Rotary locking quick joint

A rotary lock and tightening technology, which is applied in the direction of pipes/pipe joints/fittings, sealing surface connections, passing components, etc., can solve problems such as inability to lock, inconvenient disassembly, and affecting thread screwing, so as to ensure sealing and disassembly Convenience, sealing and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

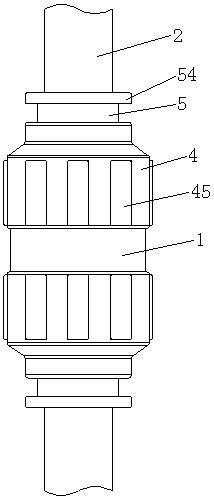

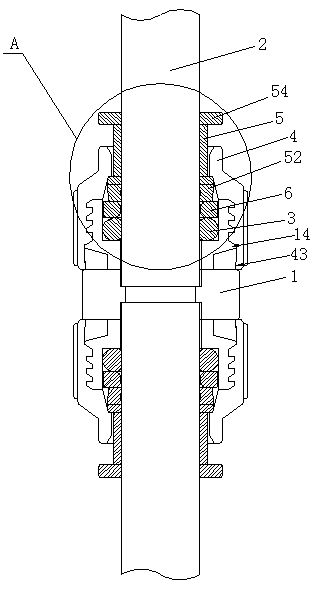

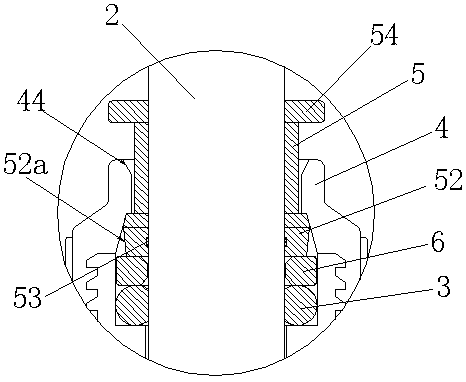

[0024] Such as Figure 1 to Figure 4 Shown is the structural representation of the present invention,

[0025] The reference signs therein are: joint body 1, connecting cavity 11, limiting edge 11a, sealing ring accommodation cavity 12, external thread 13, protruding ring 14, pipe 2, rubber sealing ring 3, locking hand wheel 4, steps Surface 41, inclined surface 42, convex edge 43, chamfer 44, convex body stripe 45, clamping piece 5, clamping shrapnel 51, convex head 52, tapered surface 52a, metal clip 53, rib 54, pressure ring 6.

[0026] Such as Figure 1 to Figure 4 as shown,

[0027] The rotary lock type quick connector includes a joint body 1, and a connecting chamber 11 that is compatible with the pipeline 2 is arranged in the joint body 1, and a sealing ring accommodation chamber 12 is arranged above the connecting chamber 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com