Gear-shifting air cylinder of synchronizer

A shifting cylinder and synchronizer technology, applied in fluid pressure actuators, elements with teeth, belts/chains/gears, etc., to reduce shifting impact, improve shifting quality, and fast shifting response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

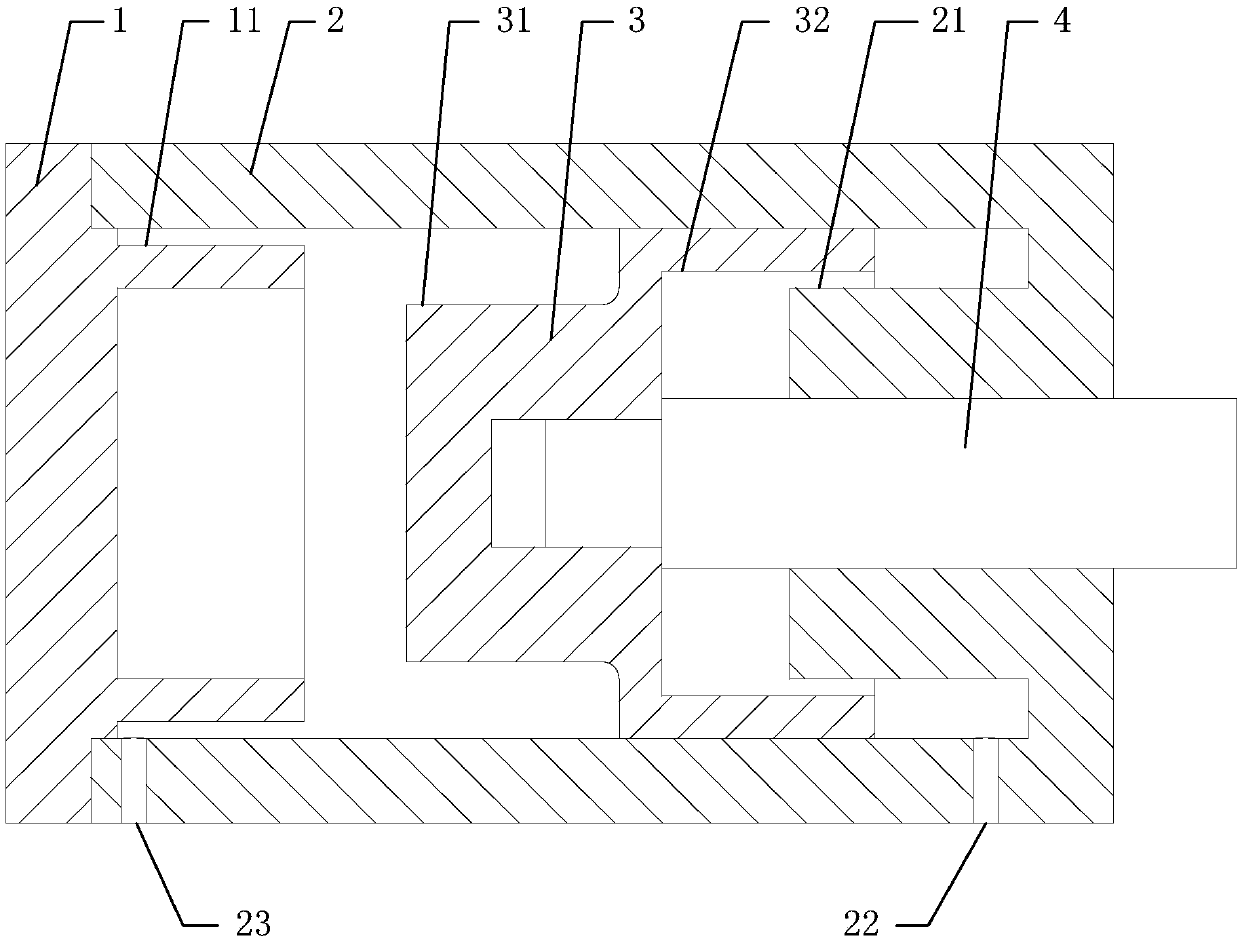

[0025] This embodiment provides a synchronizer shift cylinder, which includes an end cover 1 , a cylinder body 2 , a piston 3 and a piston rod 4 .

[0026] The end cap 1 is in the shape of a cylinder, and one end thereof is provided with an end cap boss 11. The outer surface of the end cap boss 11 is a cylindrical surface, and the inside thereof is provided with a cylindrical cavity. The end cap 1, the end cap The centerlines of the cover boss 11 and the cylindrical concave cavity are on the same straight line.

[0027] Further, the cylinder body 2 is cylindrical with one end closed, one end of its opening is connected to the end cover 1, and a cylinder boss 21 facing the end cover 1 is formed on the inner wall surface of the other end. The outer surface of the cylinder boss 21 is a cylindrical surface, and the inside is provided with a cylindrical through hole. On the side wall of the cylinder body 2, a first throttle hole 22 and a second throttle hole 23 are opened. The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com