Tempering furnace achieving vacuum gas quenching

A vacuum air quenching and tempering furnace technology, applied in the field of boiler equipment, can solve the problems of high requirements for heating elements and cooling materials, high cost, and high price, and achieve the effects of long service life, simple structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

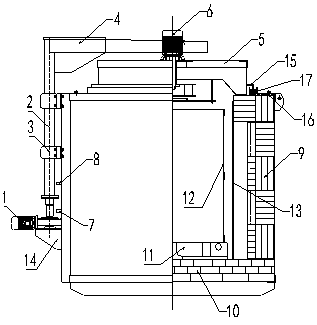

[0009] Depend on figure 1 As known, a vacuum air-quenched tempering furnace is composed of a furnace body 1, an inner tank 2 and a furnace cover 3. The furnace body 1 includes a furnace base 4, a furnace shell 5 and a furnace lining 6, and the furnace shell 5 is fixed on the furnace On the base 4, the furnace shell 5 has a furnace surrounded by a furnace lining 6, and the inner tank 2 is arranged in the furnace, and the bottom of the furnace is fixed with refractory bricks, and a barrel-shaped stainless steel inner tank 2 is fixed on the refractory bricks. With the opening facing upwards, high-strength refractory bricks have sufficient strength to withstand pressure and have good high-temperature resistance. The furnace cover 3 is fixedly equipped with a fan device 7, a hanger 8, a manual valve 9, a protective gas pipe 11, and a vacuum tube 12. For opening and closing the furnace cover 3 and the furnace body 1, a sealing ring is provided between the furnace cover 3 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com