OCA optical adhesive and preparation method thereof

An optical adhesive and optical adhesive layer technology, applied in the field of optical adhesives, can solve the problems such as affecting the OCA optical adhesive's properties such as slight tensile shrinkage and thermal shock resistance, large internal stress in the OCA adhesive layer, and difficulty in discharging monomers. , to achieve the effect of promoting the light curing process, solving the incomplete curing, and improving the curing effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

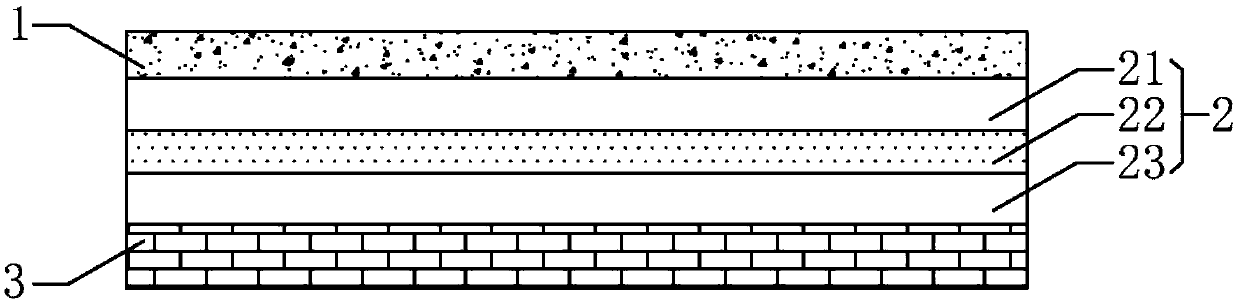

[0038] An OCA optical adhesive, comprising a light-release film layer 1, an OCA optical adhesive layer 2 and a heavy-release film layer 3 that are laminated sequentially from top to bottom, and the OCA optical adhesive layer 2 includes a laminated film layer from top to bottom The surface layer 21, the middle layer 22 and the inner layer 23, the upper surface of the surface layer 21 is attached to the lower surface of the light release film layer 1, and the lower surface of the inner layer 23 is bonded to the heavy release film layer The upper surface of 3 fits.

[0039] The light release film layer 1 is a PET release film with a release force of 5g / f; the heavy release film layer 3 is a PET release film with a release force of 30g / f; the surface layer 21 and the inner layer The Shore hardness of the layers 23 is 10A, and the Shore hardness of the intermediate layer 22 is 20A.

[0040] The thickness of the light release film layer 1 is 50 μm, the thickness of the heavy releas...

Embodiment 2

[0057] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0058] The light release film layer 1 is a PET release film with a release force of 8g / f; the heavy release film layer 3 is a PET release film with a release force of 45g / f; the surface layer 21 and the inner layer The Shore hardness of the layers 23 is 12A, and the Shore hardness of the intermediate layer 22 is 22A.

[0059] The thickness of the light release film layer 1 is 60 μm, the thickness of the heavy release film layer 3 is 88 μm; the thickness of the surface layer 21 and the inner layer 23 are both 57 μm, and the thickness of the middle layer 22 is 35 μm.

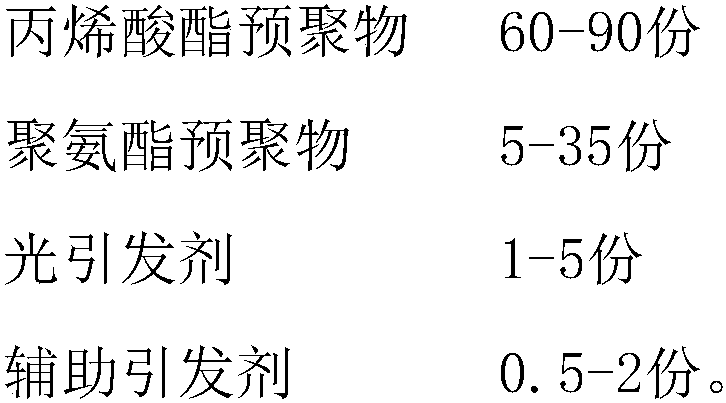

[0060] The middle layer 22 is made of the first acrylate glue, and the first acrylate glue includes the following raw materials in parts by weight:

[0061]

[0062] The photoinitiator is an α-hydroxy ketone photoinitiator, and the co-initiator is triethanolamine.

[0063] Both the surface layer 21 and the inner layer 23 ...

Embodiment 3

[0075] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0076] The light release film layer 1 is a PET release film with a release force of 12g / f; the heavy release film layer 3 is a PET release film with a release force of 65g / f; the surface layer 21 and the inner layer The Shore hardness of the layers 23 is 15A, and the Shore hardness of the middle layer 22 is 25A.

[0077] The thickness of the light release film layer 1 is 75 μm, the thickness of the heavy release film layer 3 is 100 μm; the thickness of the surface layer 21 and the inner layer 23 are both 65 μm, and the thickness of the middle layer 22 is 50 μm.

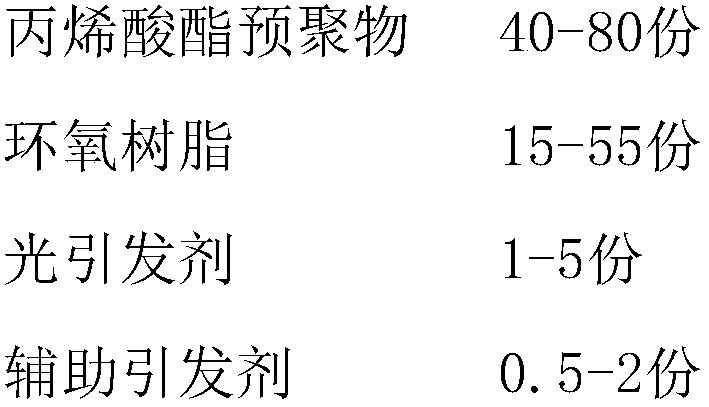

[0078] The middle layer 22 is made of the first acrylate glue, and the first acrylate glue includes the following raw materials in parts by weight:

[0079]

[0080]

[0081] The photoinitiator is an alpha-hydroxy ketone photoinitiator, the auxiliary initiator is triethanolamine; the polymerization inhibitor is a quinone po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com