Rotary spraying robot for automobile hub mold

A technology of rotary spraying, automobile wheel hub, applied in manipulators, spraying devices, manufacturing tools, etc., can solve problems such as inability to adapt to large-scale production, low quality of spraying mold release agents, threats to workers' health, etc., and achieves major engineering application value , Guarantee the effect of spraying, eliminate the effect of spraying dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

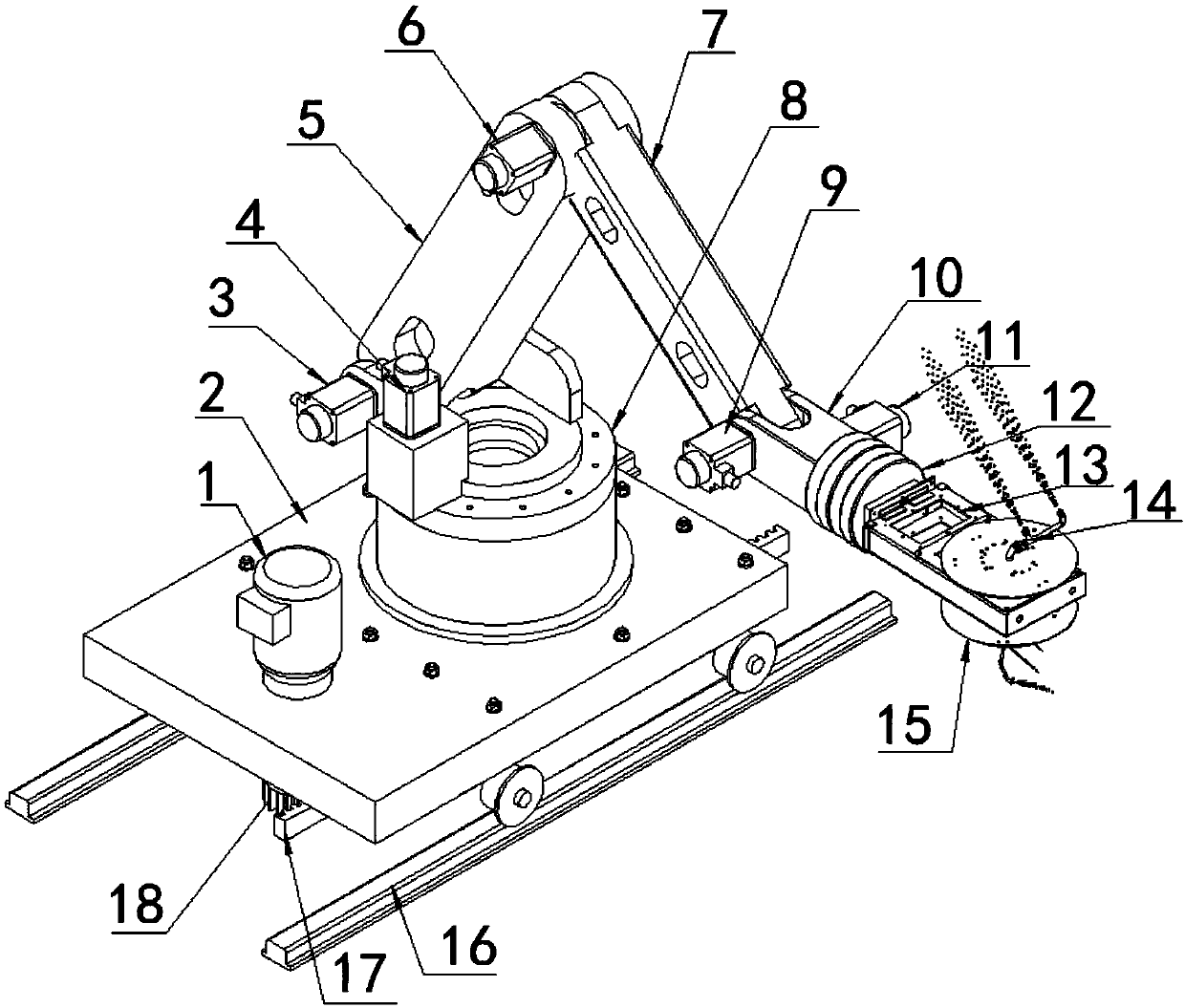

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0018] A rotary spraying robot for automobile wheel hub moulds, comprising a walking trolley 2, a rotary seat 8, a plurality of joints, a rotary arm 12 and a rotary spraying machine 15, two walking rails 16 are fixed on the ground at intervals in parallel, between the two walking rails A toothed rack 17 is installed parallel to the rails at intervals, and a walking trolley is slidably installed on the two traveling rails, and a gear 18 meshing with the rack is installed on the bottom surface of the walking trolley. Motor 1 drives. A rotating seat is fixed on the top surface of the walking trolley, and the rotating seat is driven to rotate by the rotating motor 4. Two shaft seats are fixed at symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com