Ridge array semiconductor laser and manufacturing method thereof

A technology of semiconductors and lasers, applied in the field of ridge array semiconductor lasers and its production, can solve problems such as increasing slope efficiency, reducing threshold current, affecting laser applications, etc., and achieves consistent output characteristics and uniform temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the specific embodiments set forth herein. Rather, the embodiments are provided to explain the principles of the invention and its practical application, thereby enabling others skilled in the art to understand the invention for various embodiments and with various modifications as are suited to particular intended uses.

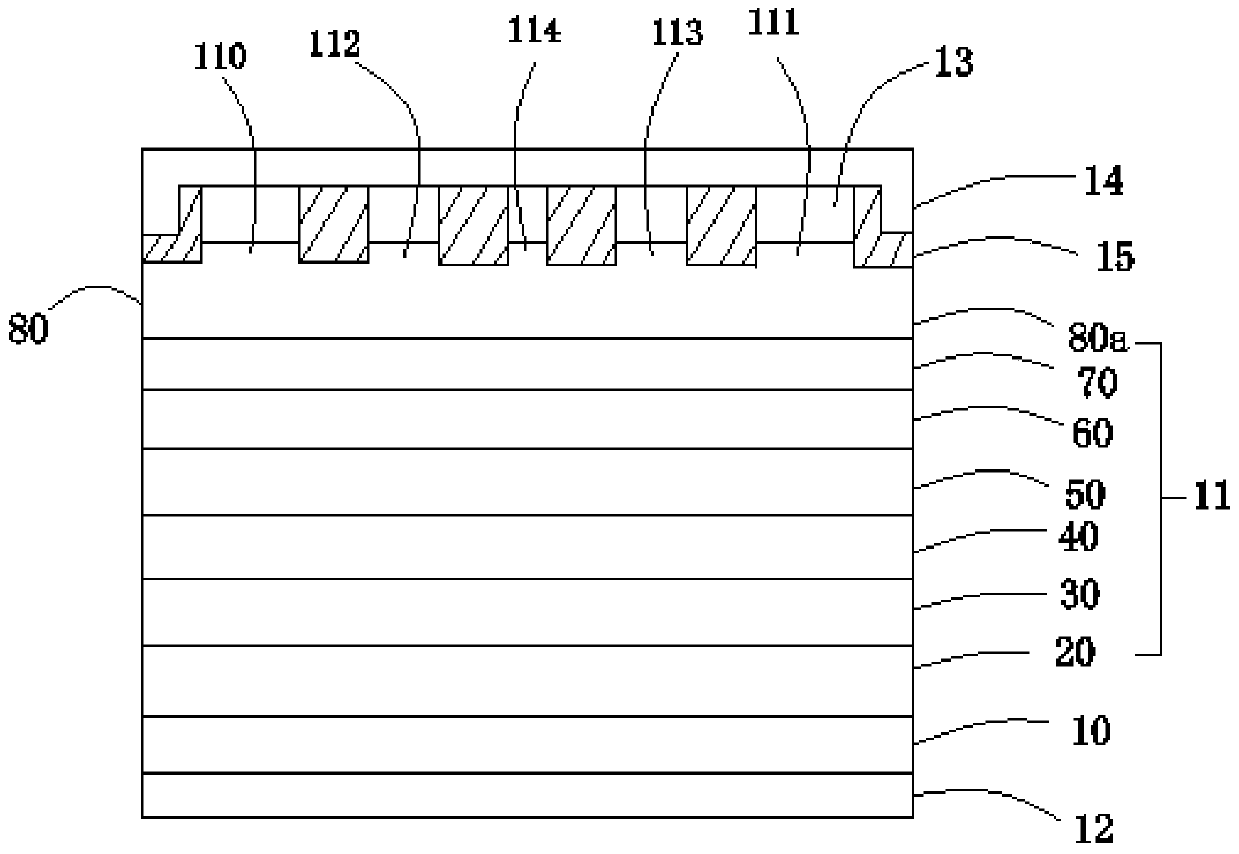

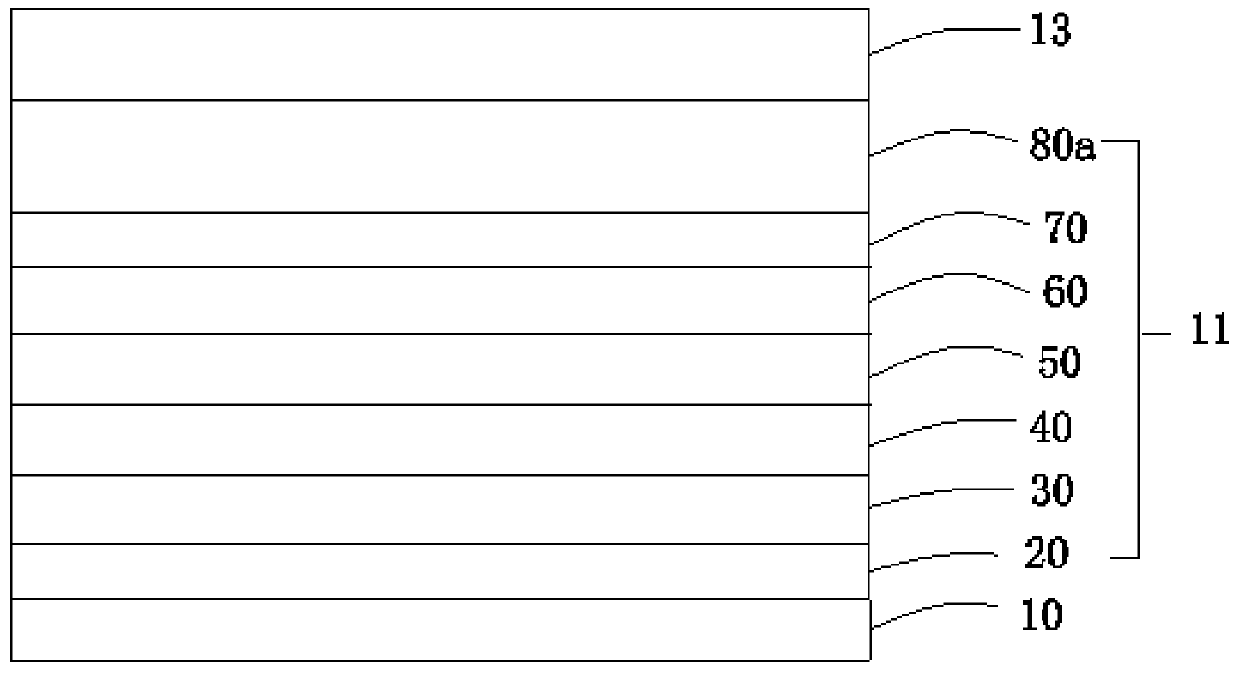

[0023] refer to figure 1 and figure 2 , the ridge array semiconductor laser provided by this embodiment includes a substrate 10, an epitaxial structure 11 formed on the top of the substrate 10; the top of the epitaxial structure 11 has a ridge-shaped semiconductor layer 80, and the ridge-shaped semiconductor layer 80 includes a plurality of ridges Shaped parts 110, 111, 112, 113, 114, wherein the widths of the plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com