Brick discharging and green brick piling dual-purpose device

A dual-purpose device, the technology of stacking blanks, applied in the directions of transportation and packaging, conveyor objects, stacking of objects, etc., can solve the problem of inability to realize fully automatic mechanized operation, inability to realize automatic operation of unloading bricks, and separation of bricks that cannot be bonded. and other problems, to achieve the effect of large clamping force, accurate grasping and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

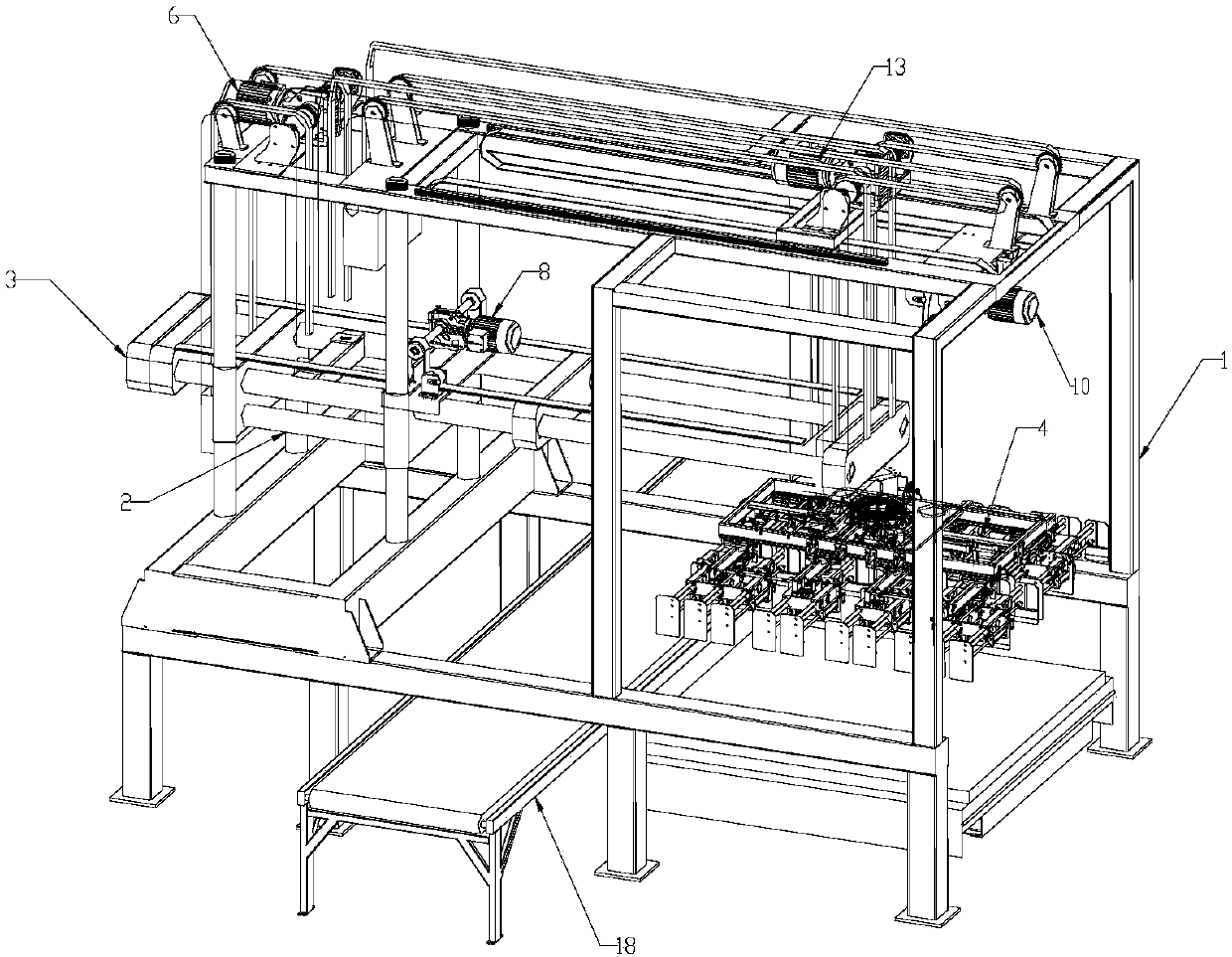

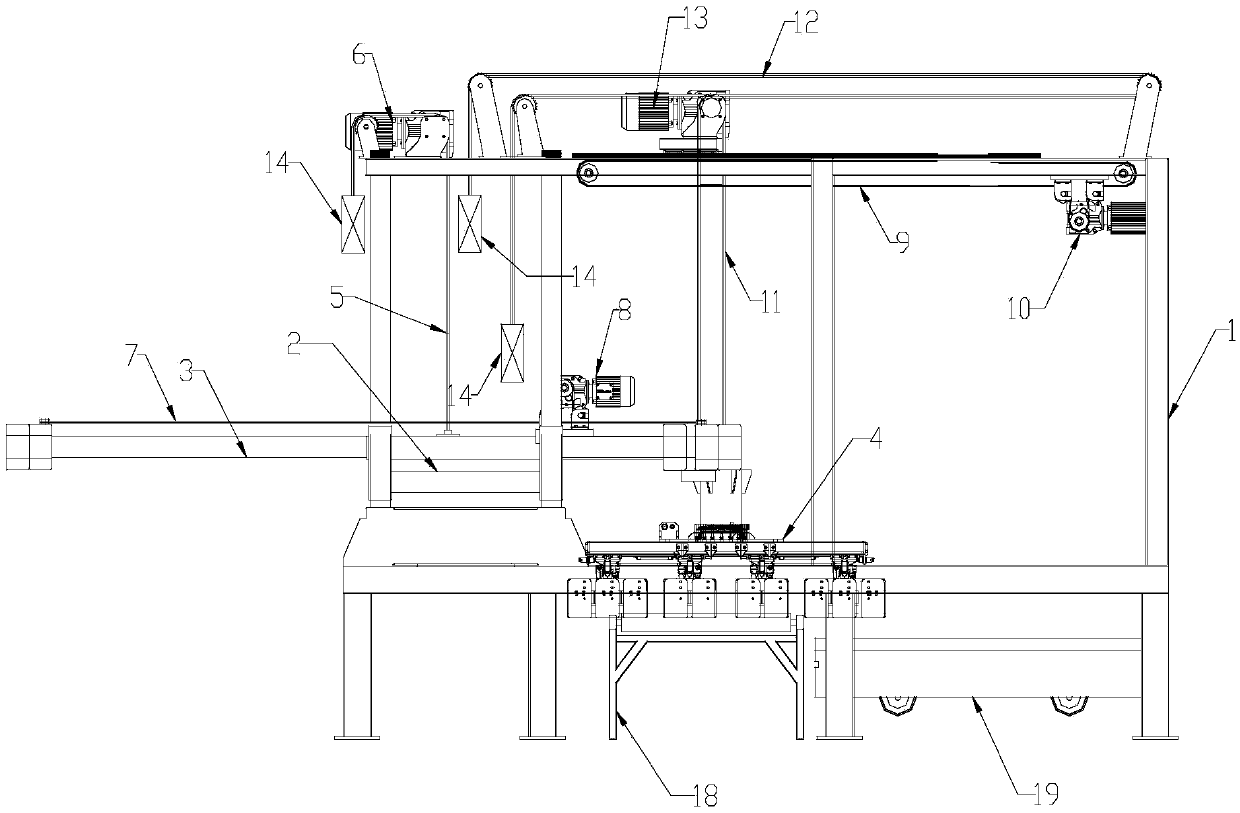

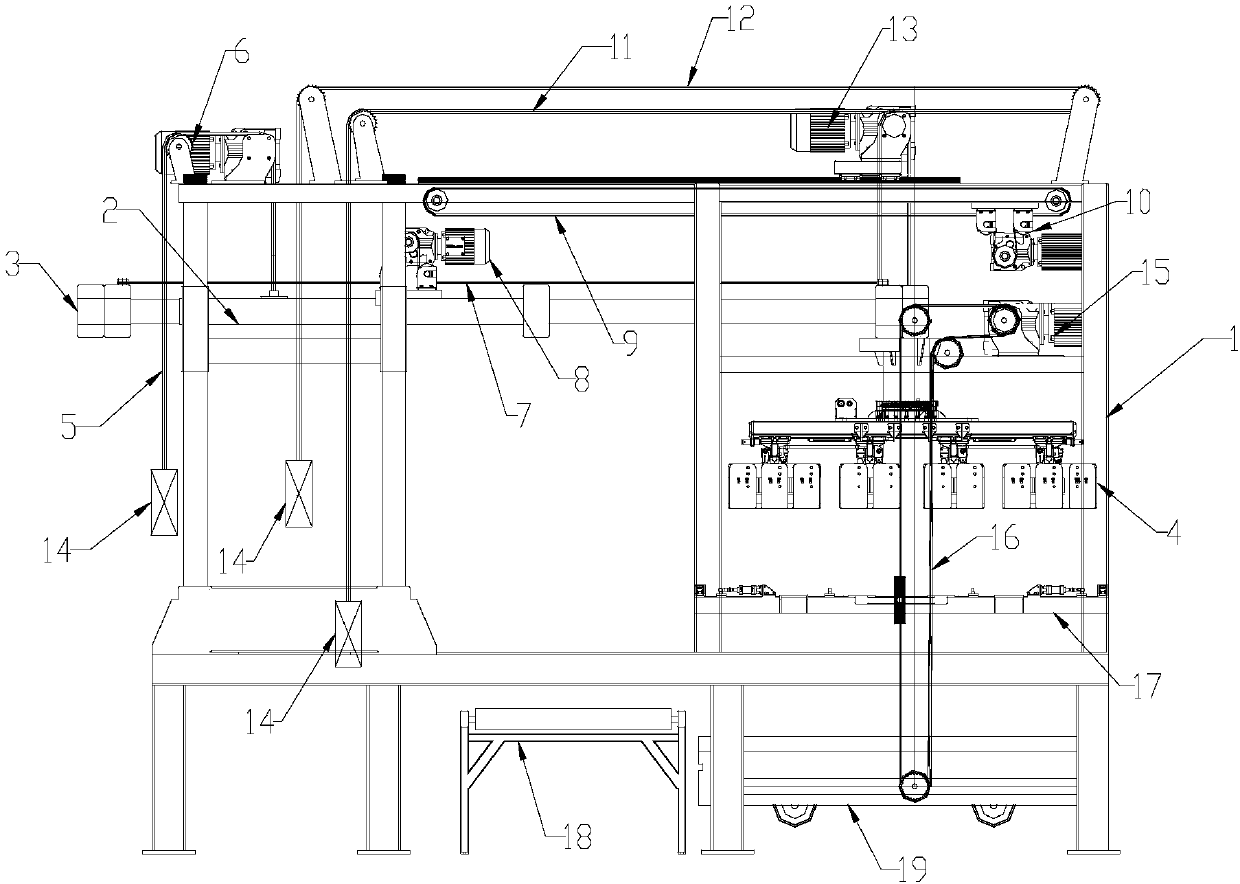

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , figure 2 , the present invention provides a dual-purpose device for unloading bricks and arbors, which includes a machine frame 1, a lifting frame 2, a laterally moving frame 3 and a chuck for unloading bricks and arbors 4, and one end of the laterally moving frame 3 is connected with a brick unloading and arbor clip The disk 4 and the lateral moving frame 3 are set in the lifting frame 2, and the lifting frame 2 is set on one side of the frame 1, and the lifting frame 2 is connected with the lifting motor 6 arranged on the top of the frame through the lifting synchronous belt 5, and the lifting synchronous belt 5 One end is connected with the counterweight 14; the lateral movement frame 3 is provided with a transverse sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com