Device for integrally assembling bearing and retainer ring for hole

A technology for retaining rings for holes and assembly devices, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problems of missing retaining rings for holes, low efficiency, and low assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments.

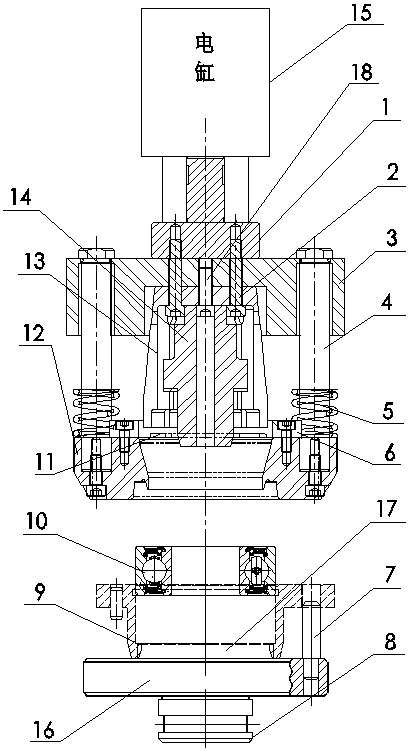

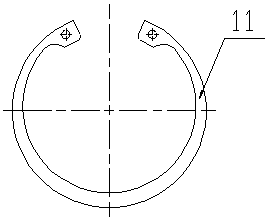

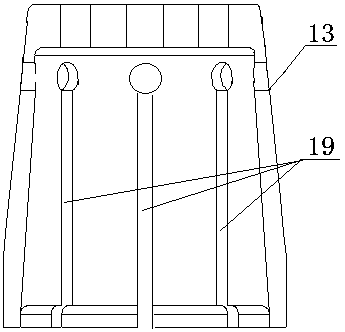

[0014] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes a linear displacement drive device, a guide seat 3, two (or three, four, etc.) guide columns 4, a spring 5, an elastic clamp tube 13, a bearing guide rod 14, and the inner holes are upper, lower, and larger. Small truncated cone-shaped funnel taper sleeve 12, limiting plate 6, workbench 16 and positioning base 8. The linear displacement driving device is a servo electric cylinder 15 (it may also be a hydraulic cylinder with a linear displacement control circuit or an air cylinder with a linear displacement control circuit). The workbench 16 is fixed on the positioning base 8, the positioning boss 17 of the assembled support frame 9 protrudes in its center, and the positioning pin 7 of the assembled support frame 9 is fixed on the edge; On the boss 17, its positioning hole is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com