Tea strip tidying machine

A technology of tea stripping machine and stripping tank, which is applied in the direction of tea treatment before extraction, which can solve the problems of easy stretching of leaves, poor tea color, and affecting the effect of tea stripping, so as to achieve the effect of improving the stripping effect and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

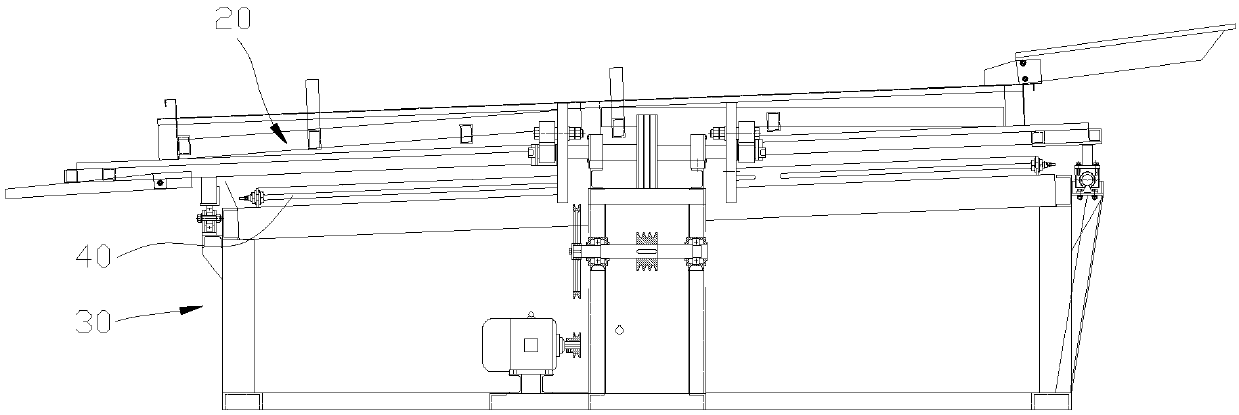

[0010] Combine below Figures 1 to 4 The present invention is described in further detail.

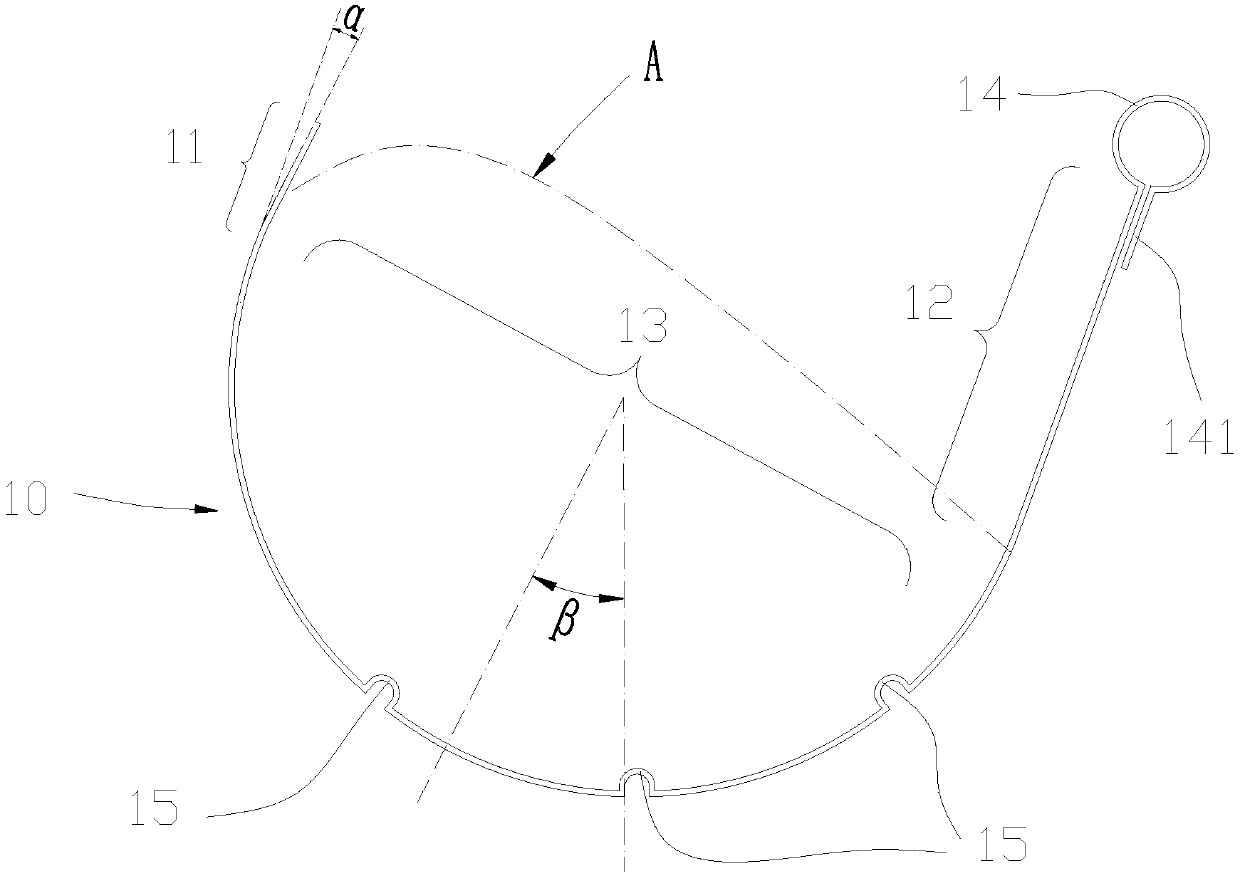

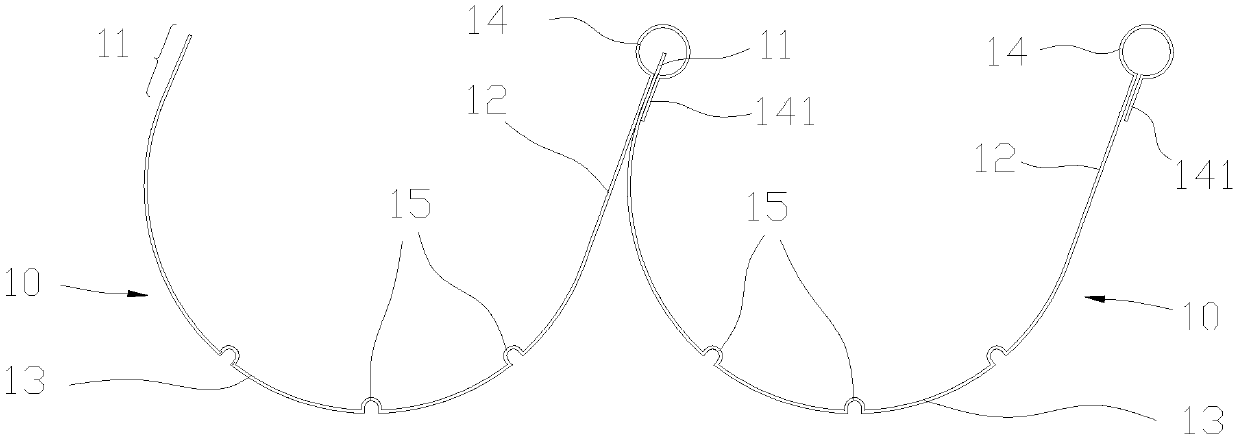

[0011] A kind of tea carding machine, comprising the frame 20 that arranges carding tank 10, and the frame 20 that is connected with drive mechanism makes reciprocating motion perpendicular to the length direction of carding tank 10, and the channel shape of carding channel 10 is U-shaped on the whole and The notch points diagonally.

[0012] In the above scheme, the groove shape of the sorting groove 10 is U-shaped as a whole and the notch is directed obliquely. figure 1 The tea leaves drop path A shown in this way not only enables the tea leaves to be heated evenly, but also ensures that the tea leaves emit moisture quickly during the process of tea leaves being thrown down, ensuring that the tea leaves are tight and prevent the leaves from drying when the strips of tea leaves are dried. Stretching, greatly improving the effect of tea leaves.

[0013] Straightening groove 10 compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com