Solid rocket motor ray batch inspection device

A batch detection, solid rocket technology, applied in the direction of using radiation for material analysis, etc., can solve the problem of low mass ray efficiency inside the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

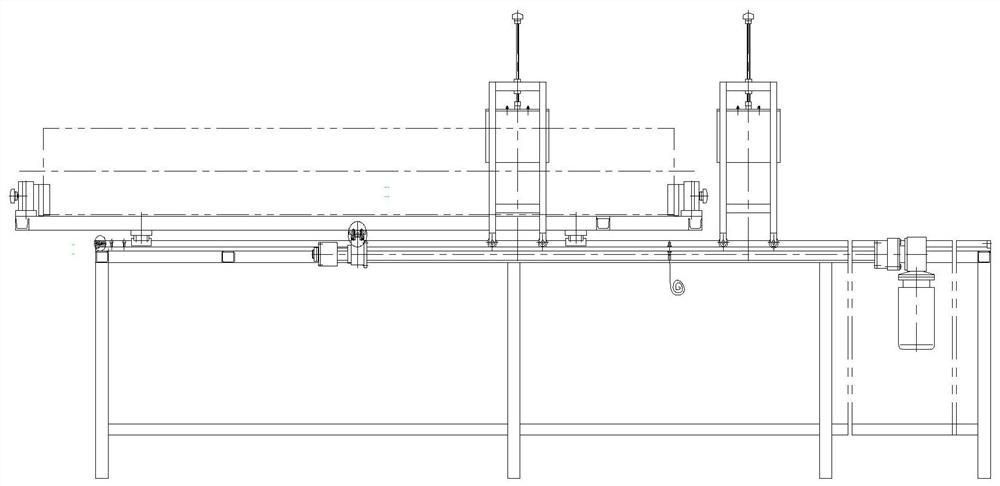

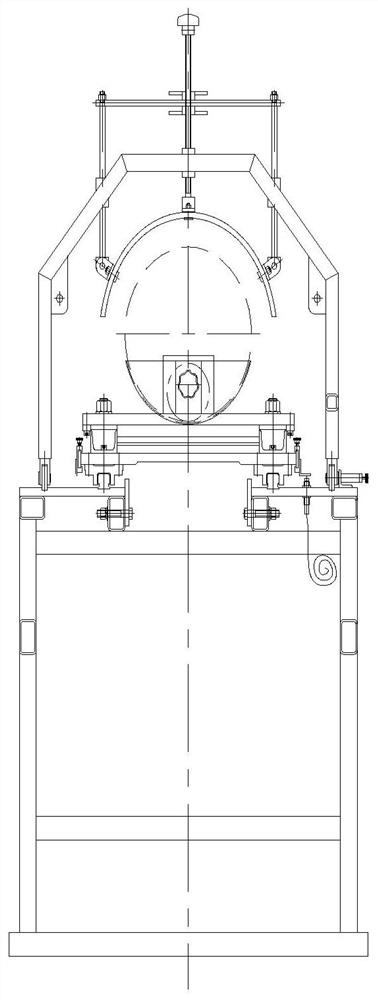

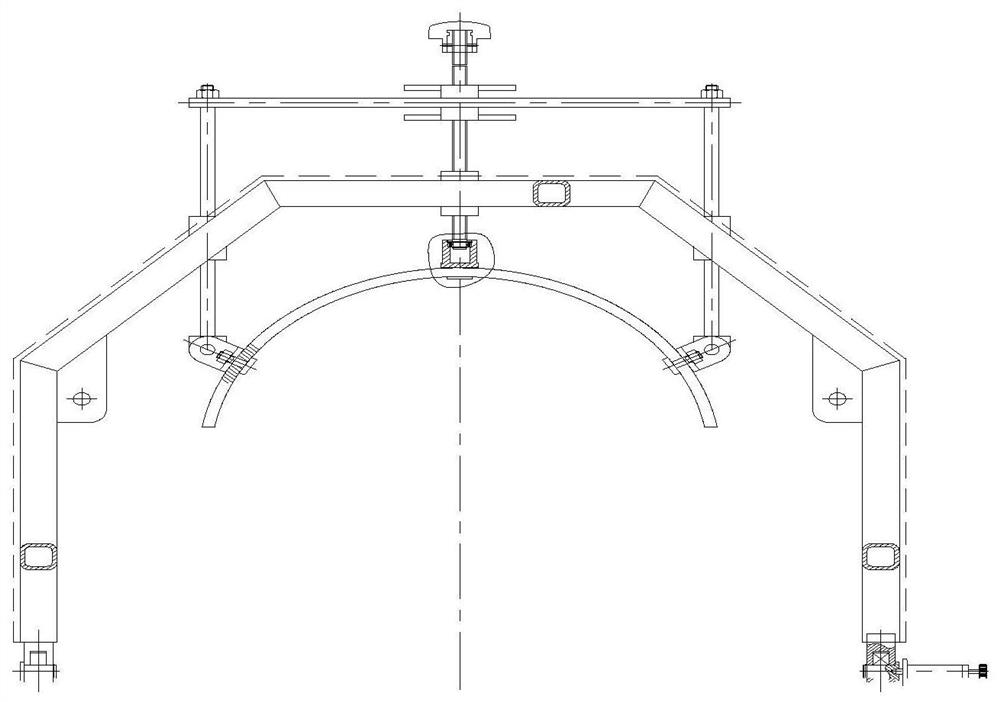

[0038] Such as Figure 1-8 As shown, the present invention provides a solid rocket motor ray batch detection device, including a ray machine, a product moving platform, a Hafu assembly, a ray shielding ring, an electrical control system, and a video monitoring system, wherein,

[0039] The two radiation shielding rings are respectively placed on both sides of the X-ray machine to form an adjustable X-ray exposure window, and the X-ray exposure window is relatively fixed on the base, and the X-ray exposure window is placed on the product mobile platform At one end, the X-ray exposure window area outside the X-ray exposure window is shielded on the product moving platform to form a radiation shielding area; the sub-products and film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com