Automobile cellular ceiling

A technology of honeycomb and ceiling, applied in the field of auto parts, can solve the problems of short-circuit burning, large volume of activated carbon package, not beautiful enough, etc., and achieve the effect of maintaining the temperature inside the car, preventing continuous water seepage and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

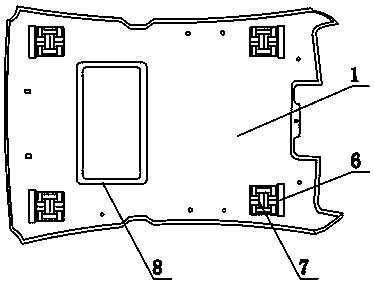

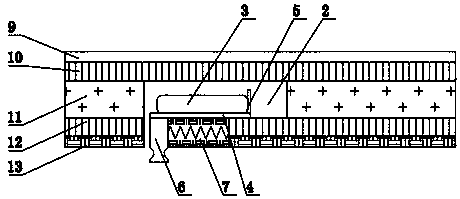

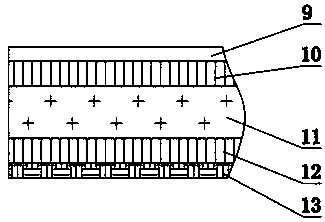

[0012] The present invention is a car honeycomb roof, comprising a honeycomb roof 1, a storage tank 2, activated carbon paper 3, a ventilating plate 4, a baffle plate 5, a handle 6, a spring fabric layer 7, a water-swellable waterstop 8, a perlite layer 9, an upper honeycomb Core 10, rubber layer 11, lower honeycomb core 12, fabric layer 13, honeycomb ceiling 1, perlite layer 9, upper honeycomb core 10, rubber layer 11, lower honeycomb core 12, fabric layer 13 are connected in sequence from outside to inside, honeycomb The four corners of the ceiling 1 are provided with storage slots 2, the storage slots 2 are embedded in the honeycomb ceiling 1, and the lower side of the storage slot 2 is installed with a ventilating panel 4, and there are small holes on the ventilating panel 4 for ventilation. A baffle 5 is arranged on the side of the panel 2, a handle 6 is installed on the lower side of the ventilating panel 2, and a spring fabric layer 7 is installed on the underside of the...

Embodiment 2

[0014] When the activated carbon paper 3 needs to be replaced, the handle 6 is pulled, and the spring in the spring fabric layer 7 contracts, and the handle 6 drives the air-permeable plate 4 to move to the inside of the storage slot 2, and a gap is generated between the handle 6 and the honeycomb ceiling 1, and the activated carbon paper 3 is placed along the gap. On the air-permeable plate 4, the side baffle plate 5 of the air-permeable plate 4 blocks the activated carbon paper 3, prevents the activated carbon paper 3 from shifting, releases the handle 6, and the spring in the spring fabric layer 7 rebounds, driving the handle 6 and the air-permeable plate 4 to return to the original position. position, the gap between the handle 6 and the honeycomb ceiling 1 is closed; when water seeps around the skylight, the water-expandable waterstop 8 around the skylight expands to seal the gap between the skylight and the honeycomb ceiling 1 to prevent further water seepage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com