Coconut shell ash ice cream

A technology of ice cream and coconut ash, applied in the direction of frozen desserts, fat production, fat oil/fat production, etc., to achieve the effect of eliminating toxins, enhancing firmness and rich coconut flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

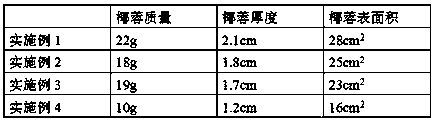

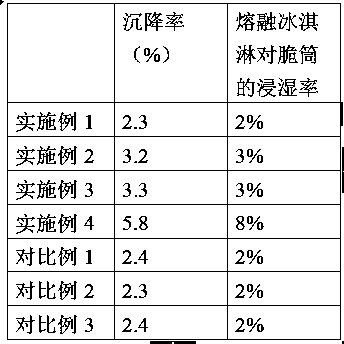

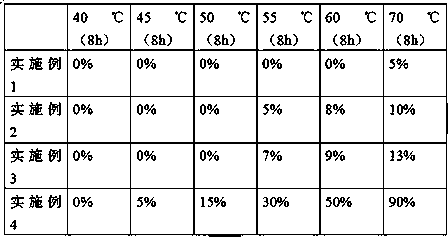

Examples

Embodiment 1

[0042] Example 1: A coconut ash ice cream: the specific preparation method is:

[0043] (1) Preparation of coconut oil: remove the coconut meat from the coconut shells, crush it, sieving to control the particle size at 40 mesh, and divide into the extraction kettle to control the pressure in the kettle to 30MPa, the temperature in the kettle to 40°C, and the stirring rate to be 1250r / min. Enter food grade CO after stirring for 45 minutes 2 , The stirring rate was changed to 650r / min, the control gas flow was 17.5L / h, kept for 40min, and the pressure was released, the separation pressure was maintained at 7.5Mpa, the separation temperature was 35℃, and the coconut oil, which was the coconut meat extract, was filtered.

[0044] (2) Preparation of natural coconut ash: select coconut shells and place them in a constant temperature oven at 125°C for 1.25h. After drying, place the dried coconut shells in a carbonization furnace. The temperature is raised to 275°C and kept under the carbon...

Embodiment 2

[0058] Example 2: A coconut ash ice cream: the specific preparation method is:

[0059] (1) Preparation of coconut oil: the coconut is shelled and the coconut meat is taken out, crushed, sieved to control the particle size at 30 mesh, and divided into the extraction kettle to control the pressure in the kettle to 20MPa, the temperature in the kettle to 30℃, and the stirring rate to be 1000r / min. After stirring for 30 minutes, pass into food grade CO 2 , The stirring rate was changed to 500r / min, the gas flow was controlled to 15L / h, kept for 30min, the pressure was released, the separation pressure was maintained at 5Mpa, the separation temperature was 30℃, and the coconut oil, which was the coconut meat extract, was filtered.

[0060] (2) Preparation of natural coconut ash: select coconut shells and place them in a constant temperature oven at 100°C for 1 hour. The dried coconut shells are placed in a carbonization furnace. The temperature is raised to 250°C and kept under the carb...

Embodiment 3

[0074] Example 3: A coconut ash ice cream: the specific preparation method is:

[0075] (1) Preparation of coconut oil: remove the coconut meat from the coconut shells, crush, sieving to control the particle size at 50 mesh, and divide into the extraction kettle to control the pressure in the kettle to 50MPa, the temperature in the kettle to 50℃, and the stirring rate to 1500r / min. Feed into food grade CO after stirring for 60 minutes 2 , The stirring rate was changed to 800r / min, the gas flow was controlled to 20L / h, kept for 50min, and the pressure was released, the separation pressure was maintained at 10Mpa, the separation temperature was 40℃, and the coconut oil was obtained by filtering the coconut extract.

[0076] (2) Preparation of natural coconut ash: select coconut shells and place them in a constant temperature oven at 150°C for 1.5 hours. Place the dried coconut shells in a carbonization furnace and heat up to 300°C and keep them ignited below the furnace. Let it be ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com