Ultraviolet sterilization intensive culture device for aquiculture

Aquaculture and ultraviolet technology, applied in gardening tools/equipment, botanical equipment and methods, applications, etc., can solve the problems of sterilization, time-consuming sterilization of uncultivated animals, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

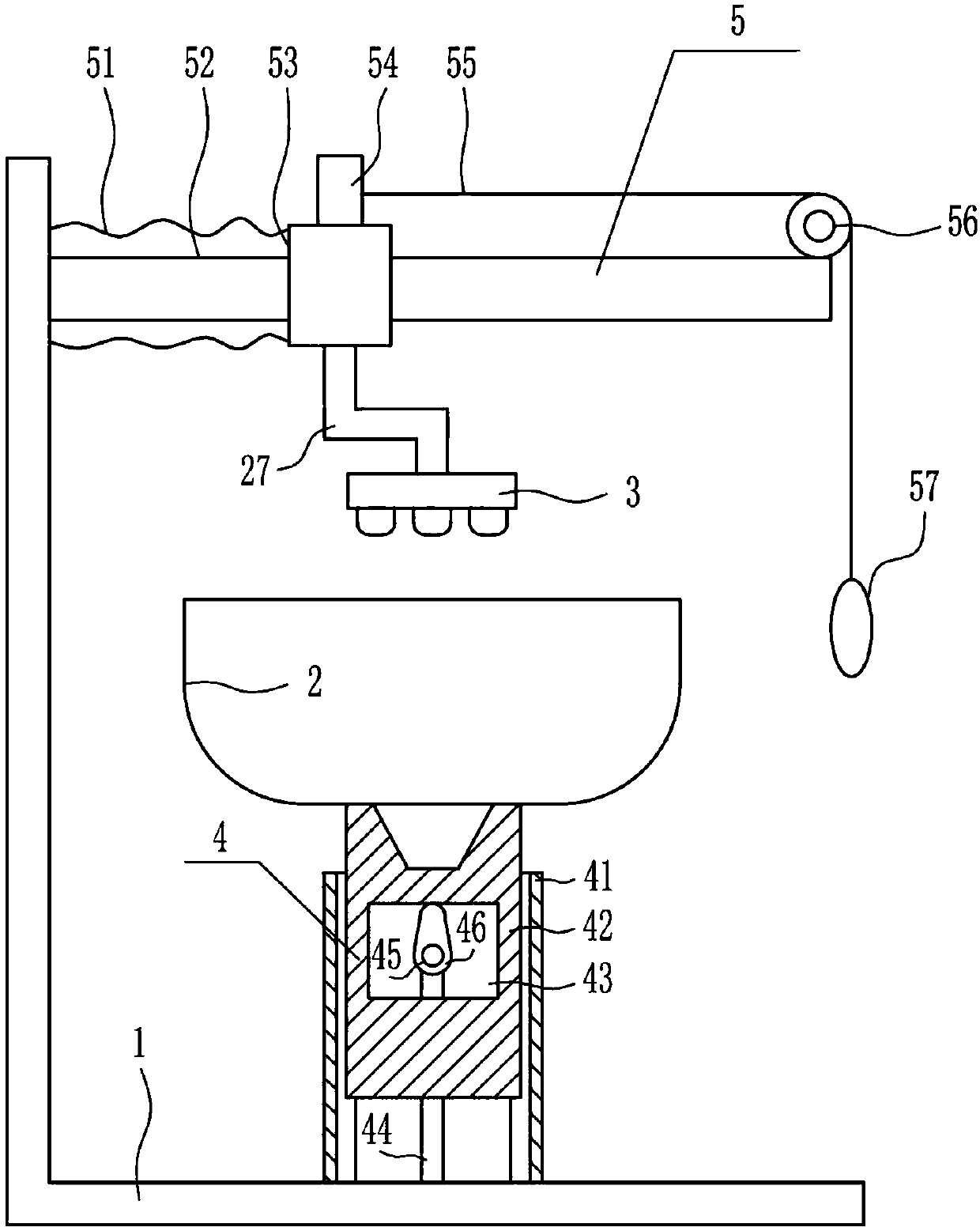

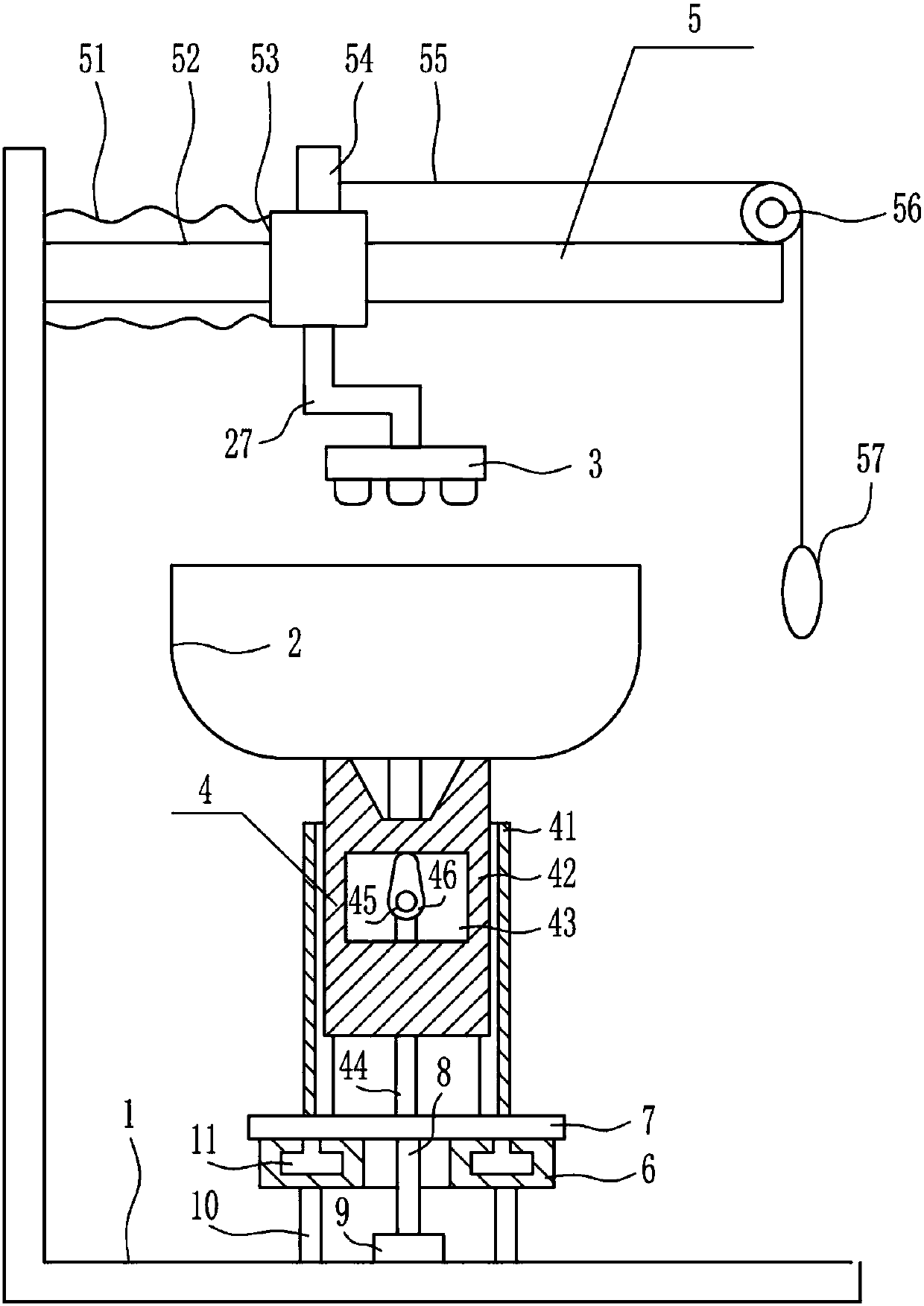

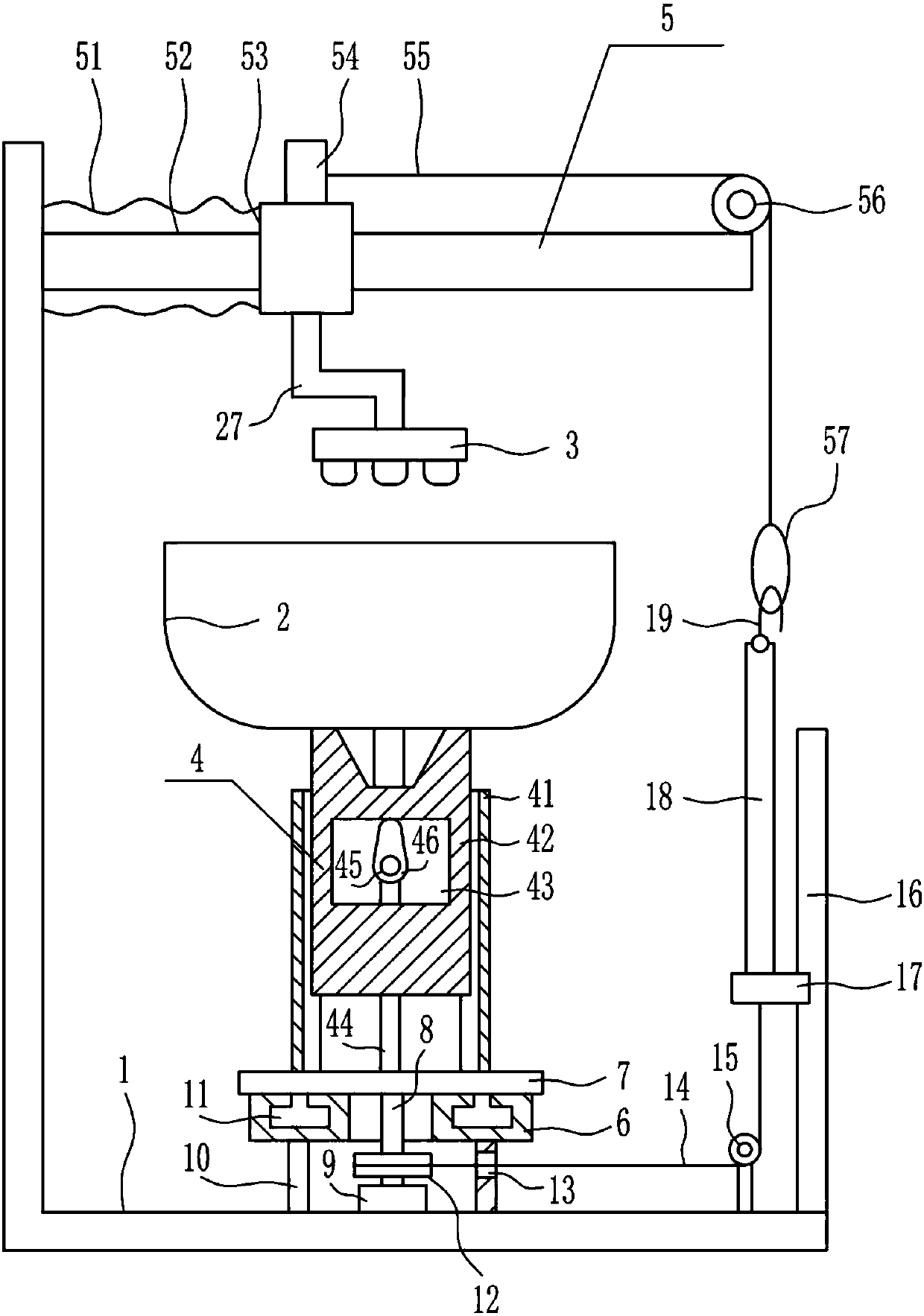

[0032] A kind of ultraviolet sterilizing intensive cultivation equipment for aquaculture, such as Figure 1-5 As shown, it includes a frame 1, a culture basin 2, an ultraviolet sterilizing lamp 3, an adjustment mechanism 4, a moving mechanism 5 and a second connecting rod 27, and an adjustment mechanism 4 is connected to the top of the frame 1, and an adjustment mechanism 4 is connected to the adjustment mechanism 4. Breeding pot 2, frame 1 inner left upper part is connected with moving mechanism 5, is connected with second connecting rod 27 on moving mechanism 5, is connected with ultraviolet sterilizing lamp 3 at the bottom of second connecting rod 27, and ultraviolet sterilizing lamp 3 is positioned at Right above the culture pot 2.

Embodiment 2

[0034] A kind of ultraviolet sterilizing intensive cultivation equipment for aquaculture, such as Figure 1-5 As shown, it includes a frame 1, a culture basin 2, an ultraviolet sterilizing lamp 3, an adjustment mechanism 4, a moving mechanism 5 and a second connecting rod 27, and an adjustment mechanism 4 is connected to the top of the frame 1, and an adjustment mechanism 4 is connected to the adjustment mechanism 4. Breeding pot 2, frame 1 inner left upper part is connected with moving mechanism 5, is connected with second connecting rod 27 on moving mechanism 5, is connected with ultraviolet sterilizing lamp 3 at the bottom of second connecting rod 27, and ultraviolet sterilizing lamp 3 is positioned at Right above the culture pot 2.

[0035] The adjustment mechanism 4 includes a slideway 41, a moving block 42, a first connecting rod 44, a first motor 45 and a cam 46. The left and right symmetrical slideway 41 is connected in the middle of the top of the frame 1, and the ins...

Embodiment 3

[0037] A kind of ultraviolet sterilizing intensive cultivation equipment for aquaculture, such as Figure 1-5 As shown, it includes a frame 1, a culture basin 2, an ultraviolet sterilizing lamp 3, an adjustment mechanism 4, a moving mechanism 5 and a second connecting rod 27, and an adjustment mechanism 4 is connected to the top of the frame 1, and an adjustment mechanism 4 is connected to the adjustment mechanism 4. Breeding pot 2, frame 1 inner left upper part is connected with moving mechanism 5, is connected with second connecting rod 27 on moving mechanism 5, is connected with ultraviolet sterilizing lamp 3 at the bottom of second connecting rod 27, and ultraviolet sterilizing lamp 3 is positioned at Right above the culture pot 2.

[0038] The adjustment mechanism 4 includes a slideway 41, a moving block 42, a first connecting rod 44, a first motor 45 and a cam 46. The left and right symmetrical slideway 41 is connected in the middle of the top of the frame 1, and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com