Anti-leakage structure and method of shot blasting machine

A shot blasting machine, anti-leakage technology, applied in the field of machinery, can solve the problems of shot and dust leakage, easy bearing wear, bearing foreign matter noise, etc., to achieve the effect of internal cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

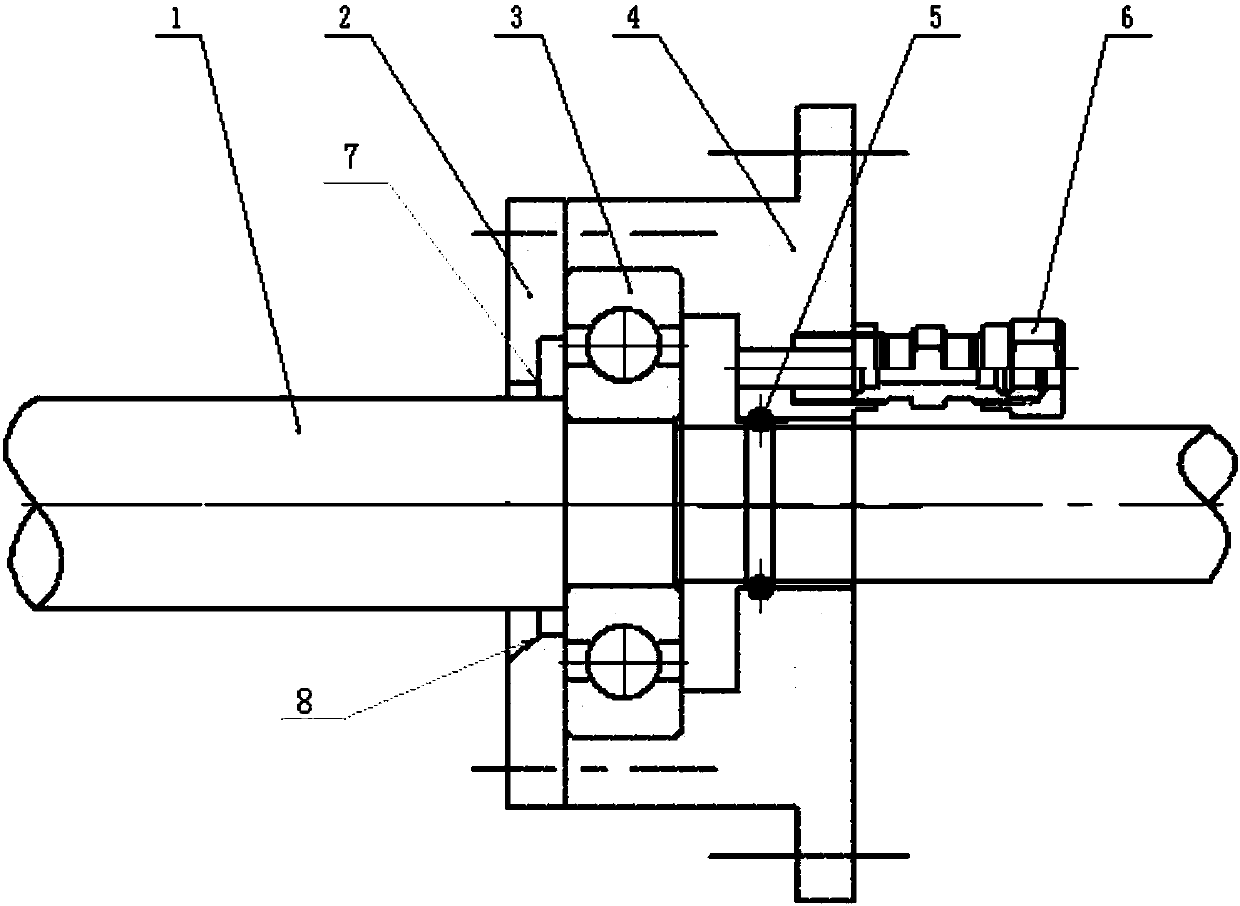

[0021] Such as figure 1 As shown, a shot blasting machine anti-leakage structure, which includes a bearing end cover 2, a bearing 3, and a bearing seat 4 arranged along the shaft 1, the bearing 3 is arranged in the bearing end cover 2 and the bearing seat 4, and at the bearing end The upper end of the inner side of the cover 2 is provided with an air inlet passage 7, and the lower end of the inner side of the end cover is provided with a pill return outlet 8. The anti-leakage structure of the shot blasting machine disclosed in the present invention blows high-pressure air from the outside inward through the gap between the inner and outer rings of the bearing 3, forming a high-pressure air curtain inside the bearing 3 to prevent pellets and dust from flying into the bearing 3. If a small amount of dust flies in, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com