Sandwich sinking pipe connector and production method thereof

A sandwich and immersed tube technology, which is applied in construction, artificial islands, infrastructure engineering, etc., can solve problems such as inability to meet the requirements of submarine immersed tubes, and achieve the effects of reducing quality risks, simple production processes, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

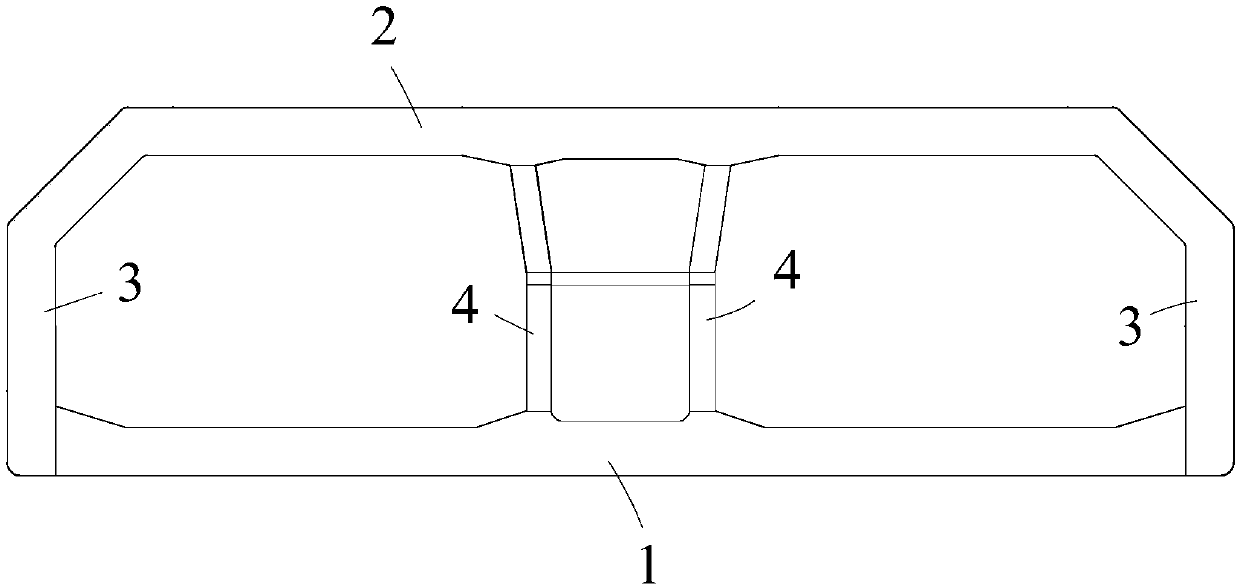

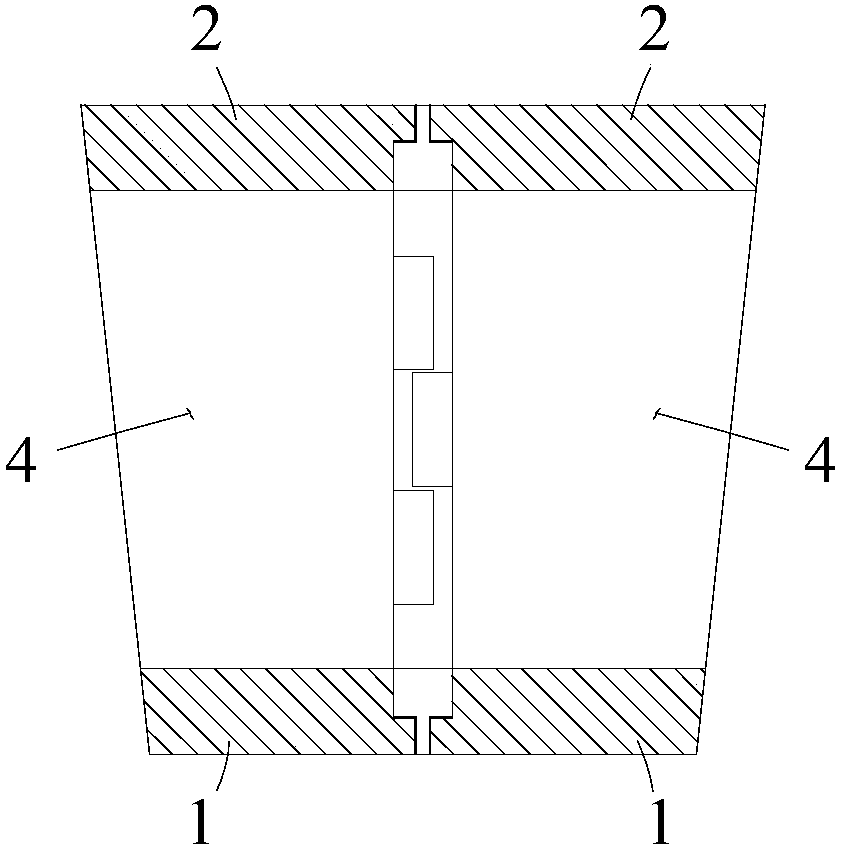

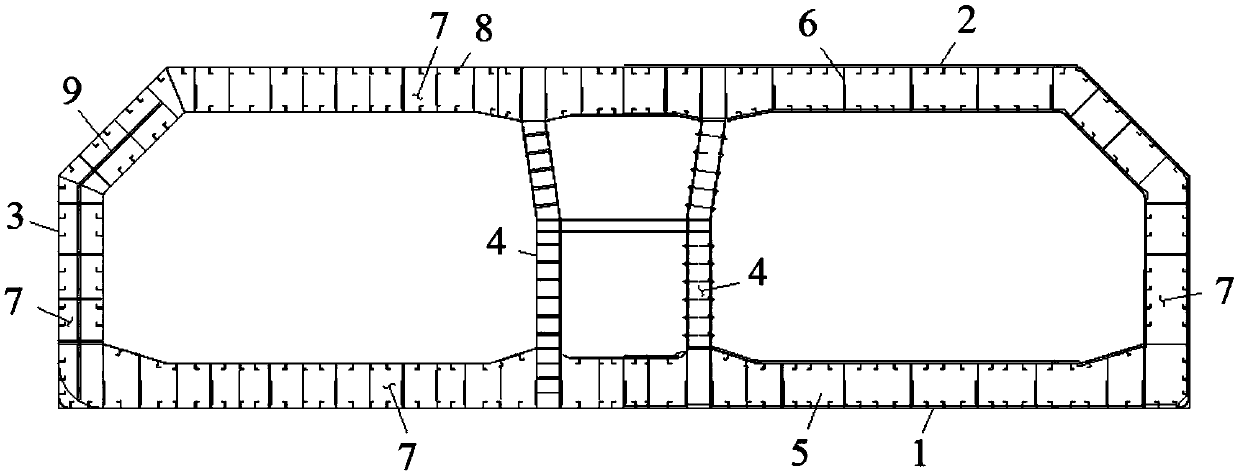

[0040] like Figure 1-5As shown, a sandwich immersed pipe joint includes a ring-shaped steel structure shell composed of a bottom plate 1, a top plate 2, and a side wall 3 connected between the bottom plate 1 and the top plate 2, and a number of longitudinal partitions are arranged in the shell. Plates 6 and transverse partitions 7, all of the transverse partitions 7 and longitudinal partitions 6 separate the housing into several mutually independent compartment units 5; each of the compartment units 5 is also provided with several Stiffening panels, each of the compartment units 5 is filled with concrete 12 .

[0041] like Figure 4-5 As shown, each of the longitudinal partitions 6 described above is arranged along the longitudinal direction of the steel structure shell, and each of the transverse partition plates 7 is arranged along the lateral direction of the steel structure shell. All the longitudinal partitions 6 and transverse partitions 7 are welded to the bottom pla...

Embodiment 2

[0046] The present invention also provides a method for producing the above-mentioned sandwich immersed pipe joint, comprising the following steps:

[0047] Step 1: Pretreatment of the steel plate. According to the prefabricated shape of the immersed pipe joint, each part of the immersed pipe joint is formed, including the steel plates required for the pretreatment of the top plate 2, the bottom plate 1, and the side wall 3; specifically, it can be based on the size of the design drawings. , Consider the deviation in the processing process, the tolerance required for assembly, the gap and the inversion value, as well as the shrinkage in the process of welding and flame correction. After calculating the precise size, reasonable lofting is carried out. Steel plate pretreatment, cutting and blanking. The plate unit is welded by two-way anti-deformation frame and multi-head portal automatic welding machine in the production, which can effectively control the welding deformation, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com