An energy-saving heat treatment furnace

A heat treatment furnace and furnace body technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

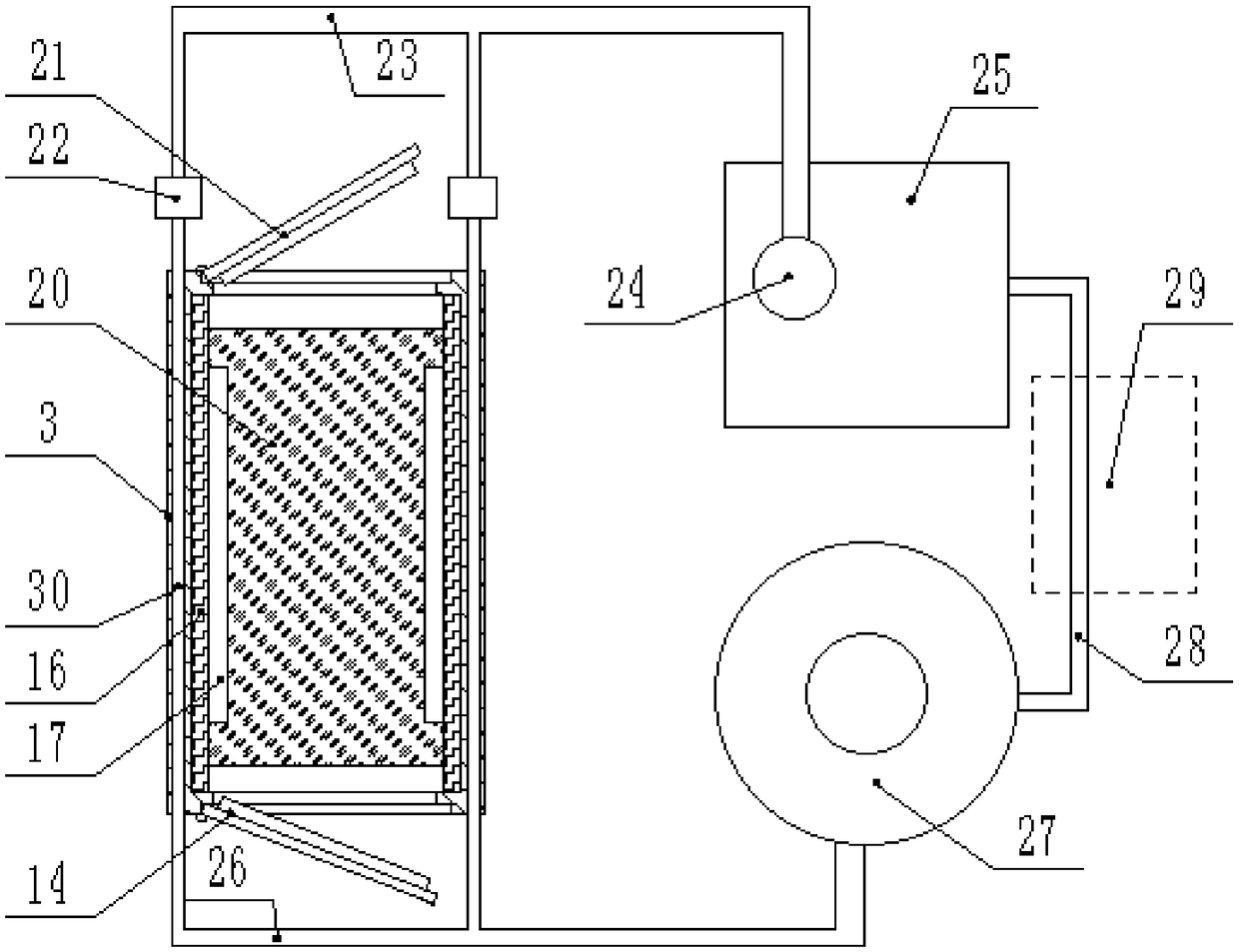

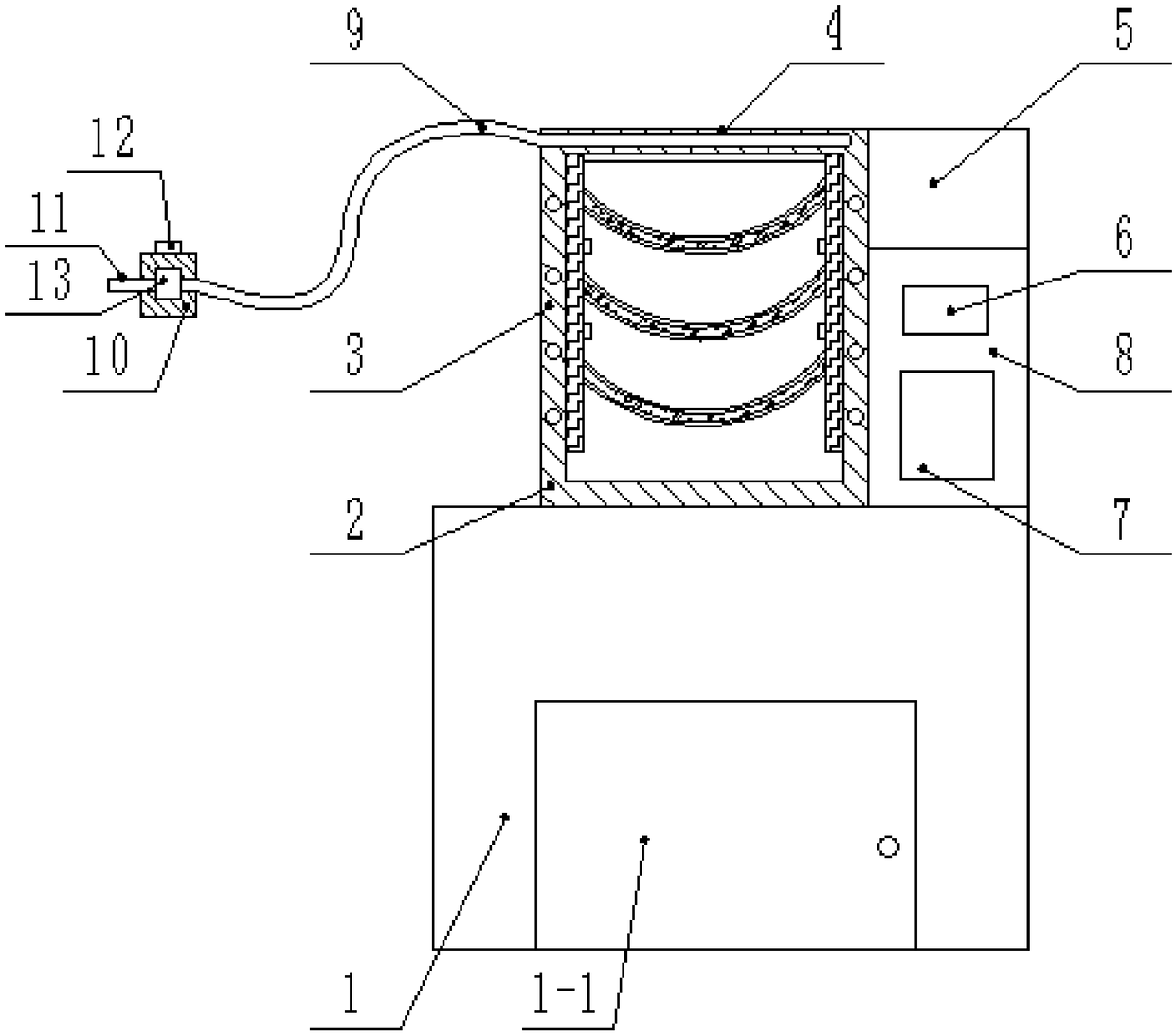

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

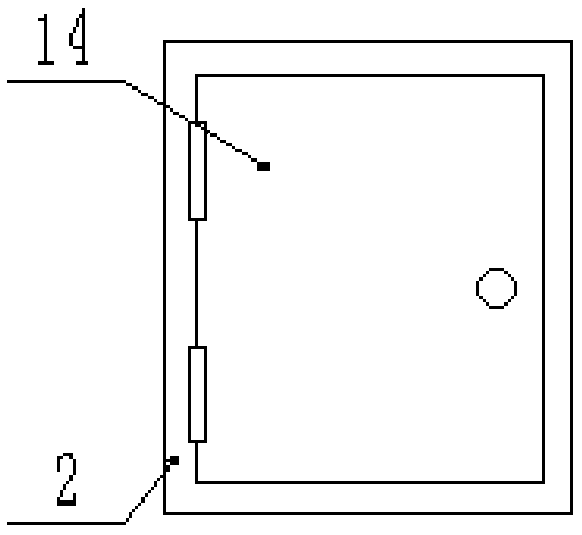

[0020] Such as Figure 1 to Figure 5 As shown, an energy-saving heat treatment furnace includes a base 1, the front of the base 1 is provided with a hinged door 1-1, the upper end of the base 1 is fixed with a furnace body 2, and the furnace body 2 includes two side plates 3 and the top plate 4, the side plate 3 is provided with a coiled water pipe 30, the interior of the top plate 4 is provided with a coiled pipe B15, the inner side of the side plate 3 is fixed with a heat insulation layer 16, and the heat insulation layer 16 Above the inner bottom of the furnace body 2, several arc-shaped heat-resistant bricks 19 are fixed between the heat-insulating layers 16, and a heating layer B20 is fixed on the outer end of the heat-resistant bricks 19. The heat-resistant bricks 19 A heating luminescent tube 17 fixed on the side of the heat insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com