Portable optical cable fusion welding operating platform

An operation platform and portable technology, which is applied to the fixed work of ADSS optical cable joints, power system operation platforms, and portable optical cable fusion operation platforms, can solve the problems of unstable fixation when optical cables are connected, achieve a wide range of use, shorten welding time, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

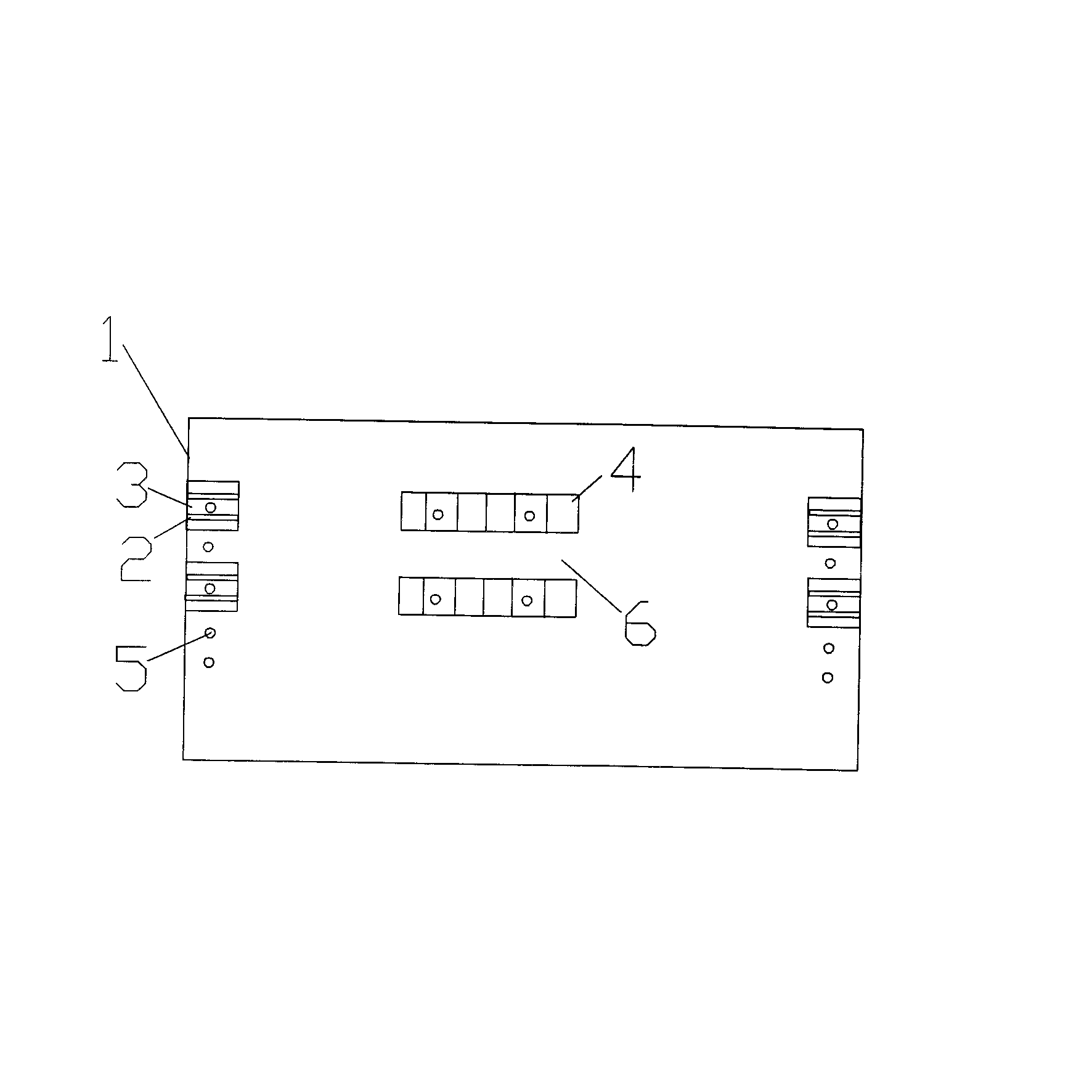

[0020] As shown in the figure, including a platform 1, a plurality of adjustment threaded holes 5 are provided on both sides of the edge of the platform, and the bolts fix the rubber splint 3 on the platform, and the adjustment threaded holes match the splint threaded holes. Grooves 2 are arranged on both sides of the splint, and the distance between the two grooves matches the distance between the two optical cables on the optical cable splice box. The rubber grooves can be adjusted according to the thickness of the optical cables. The center of the platform 1 is provided with a plurality of central adjustment threaded holes, two rubber baffles 4 are fixed on the center of the platform by bolts, the central adjustment threaded holes match the baffle threaded holes, and the two rubber baffles form a fixing slot 6 .

[0021] The present invention was tested in the whole process of line connection work in a communication rural network project, with a total of 64 melting heads, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com