Seven-day wine making method

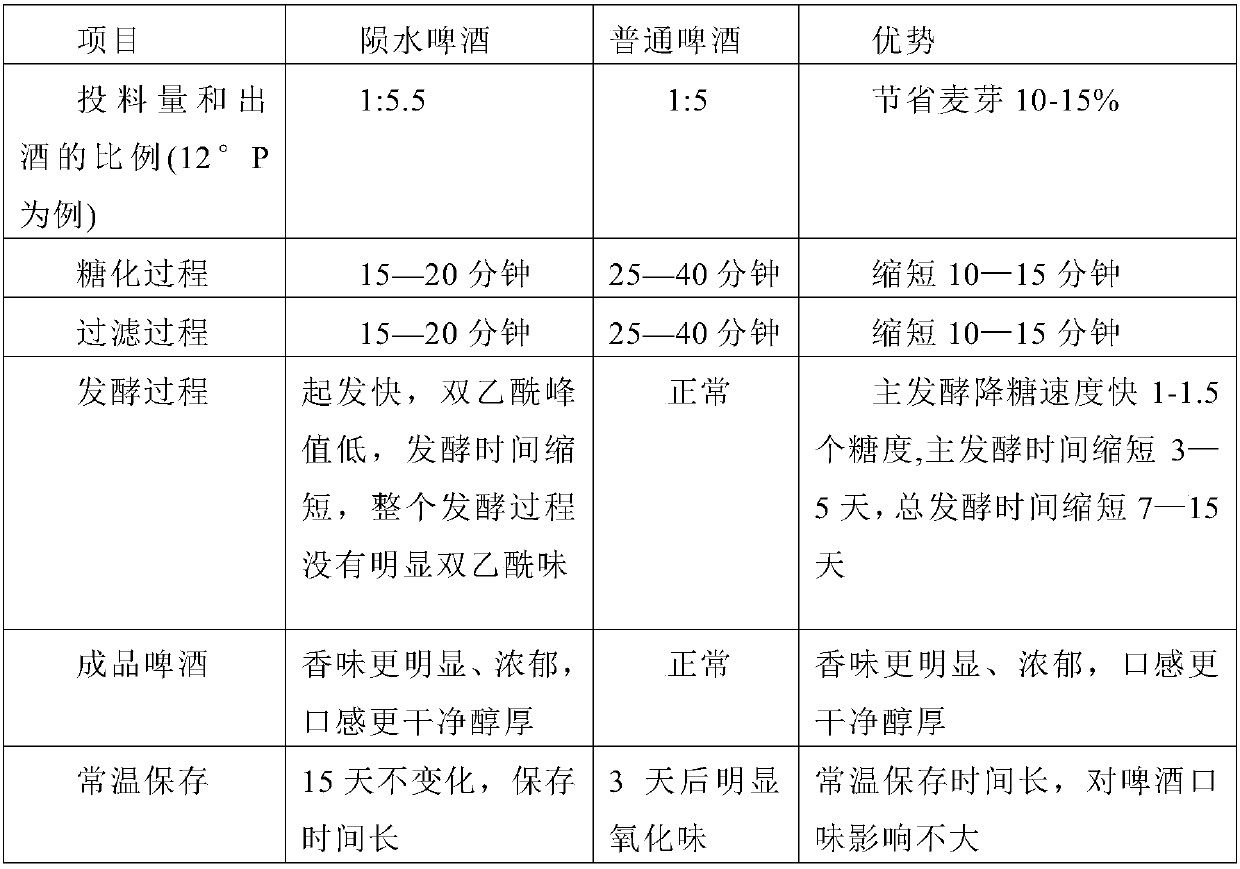

A wort and meteorite technology, applied in the field of seven-day brewing, can solve the problems of long fermentation time, long fermentation time, complicated process, etc., and achieve the effects of improving quality and taste, increasing production capacity and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Dark beer example 1 (1000L wort as an example)

[0052] A. Raw material ratio and crushing: 135kg of light malt, 27kg of scorched malt, 9kg of wheat malt and 9kg of black malt. Mix the raw materials and pulverize after mixing. The degree of pulverization is controlled so that the husk is broken and not broken, that is, fine powder and coarse The ratio of grain to wheat husk is 3:3:4 to obtain the primary mixture;

[0053] B. Saccharification: first add 650L of water to the saccharification tank, the mass ratio of the amount of water added to the total amount of materials added is 1:3.6, and when the temperature in the saccharification tank rises to 52°C, add 800ml of water first The meteorite quick-forming agent, fully stir evenly, then add all the primary mixture materials in step A into the saccharification tank, stir well, keep it for 10 minutes, then raise the temperature in the saccharification tank to 63°C and keep it for 20 minutes. Continue to heat up the saccharifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com