Fireproof flame-retardant plastic flooring and manufacture method thereof

A technology for plastic floor, fire and flame retardant, applied in the fields of plastic floor and its preparation, polyacrylic acid pentabromo, alkene nitrile copolymer 42-56, can solve problems such as poor fire resistance and flame retardancy, and achieve improved flame retardancy, The effect of low smoke production and high oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A fire-resistant and flame-retardant plastic floor, made of the following raw materials by weight (kg): polyphenylene sulfide 78, vinyl chloride-acrylonitrile copolymer 42, polyacrylate pentabromobenzyl 22, antimony trisulfide 8, hexasil Magnesium acid 10, polyphenylsulfone diphenyl phosphonate 15, methyl pentachlorostearate 13, expandable graphite 10, tris(2,3-dibromopropyl) isocyanurate 4, boric acid tris 7 isooctyl ester, 5 zirconium oxychloride, 9 sodium tungstate, 14 dicyclohexyl phthalate, 8 dioctyl tetrachlorophthalate, 5 chlorinated paraffin, 13 high alumina fine powder.

[0015] A method for preparing a fire-resistant and flame-retardant plastic floor, comprising the following steps:

[0016] (1) Polyphenylene sulfide, vinyl chloride-acrylonitrile copolymer, pentabromobenzyl polyacrylate, polyphenylsulfone diphenyl phosphonate, methyl pentachlorostearate, dicyclohexyl phthalate , Add chlorinated paraffin into the high-speed mixer, mix at 80-90°C for 4-8 minute...

Embodiment 2

[0021] A fire-resistant and flame-retardant plastic floor, made of the following raw materials in weight (kg): polyphenylene sulfide 84, vinyl chloride-acrylonitrile copolymer 50, polyacrylate pentabromobenzyl 27, antimony trisulfide 11, hexasil Magnesium acid 13, polyphenylsulfone diphenyl phosphonate 20, methyl pentachlorostearate 17, expandable graphite 12, tris(2,3-dibromopropyl) isocyanurate 7, boric acid tris Isooctyl ester 10, zirconium oxychloride 8, sodium tungstate 13, dicyclohexyl phthalate 16, dioctyl tetrachlorophthalate 11, chlorinated paraffin 8, high aluminum fine powder 14.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] A fire-resistant and flame-retardant plastic floor, made of the following raw materials in weight (kg): polyphenylene sulfide 91, vinyl chloride-acrylonitrile copolymer 56, polyacrylate pentabromobenzyl 34, antimony trisulfide 14, hexasil Magnesium acid 15, polyphenylsulfone diphenyl phosphonate 25, methyl pentachlorostearate 19, expandable graphite 15, tris(2,3-dibromopropyl) isocyanurate 9, boric acid tris Isooctyl 13, zirconium oxychloride 10, sodium tungstate 16, dicyclohexyl phthalate 19, dioctyl tetrachlorophthalate 14, chlorinated paraffin 10, high alumina fine powder 17.

[0025] The preparation method is the same as in Example 1.

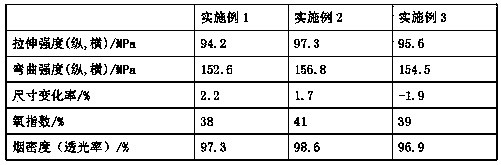

[0026] The performance test results of the plastic floor made in the above-mentioned Examples 1-3 are shown in the table below.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com