Commercial vehicle long-oil-change-cycle hub assembly and adjustment method thereof

A wheel hub and assembly technology is applied in the field of commercial vehicle long oil change wheel hub assembly and its assembly and adjustment, which can solve the problems of frequent maintenance, few maintenance times and high maintenance costs, and achieves improved maintenance interval mileage and maintenance. Low cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

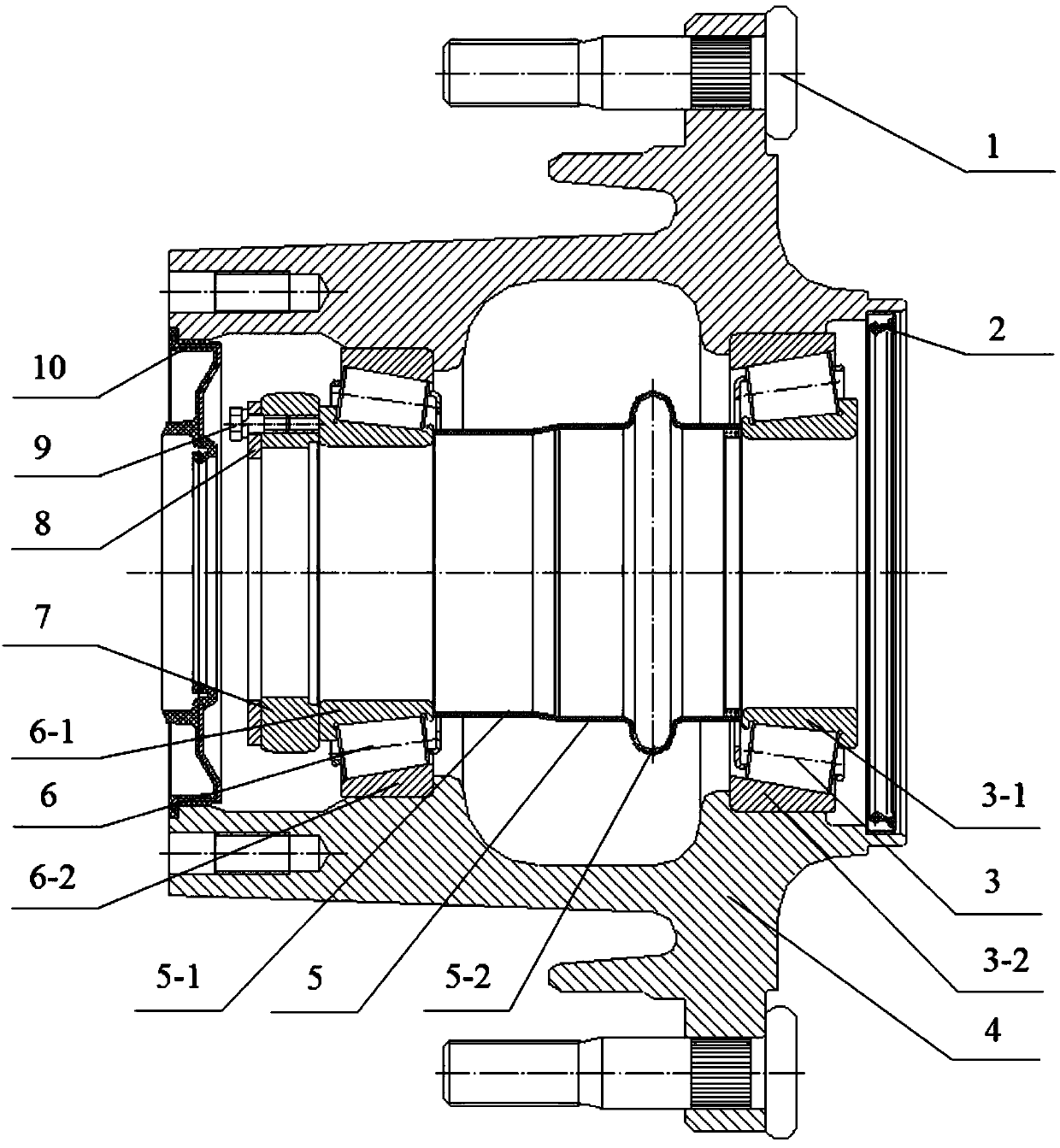

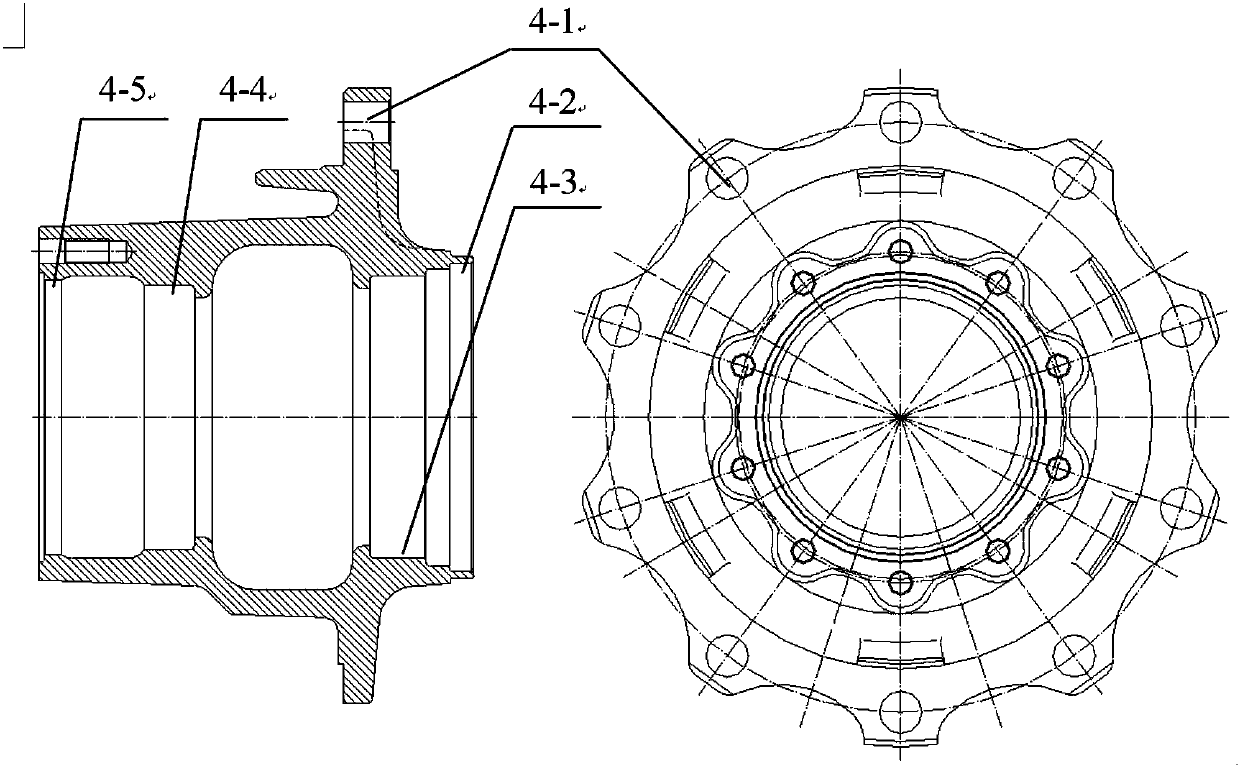

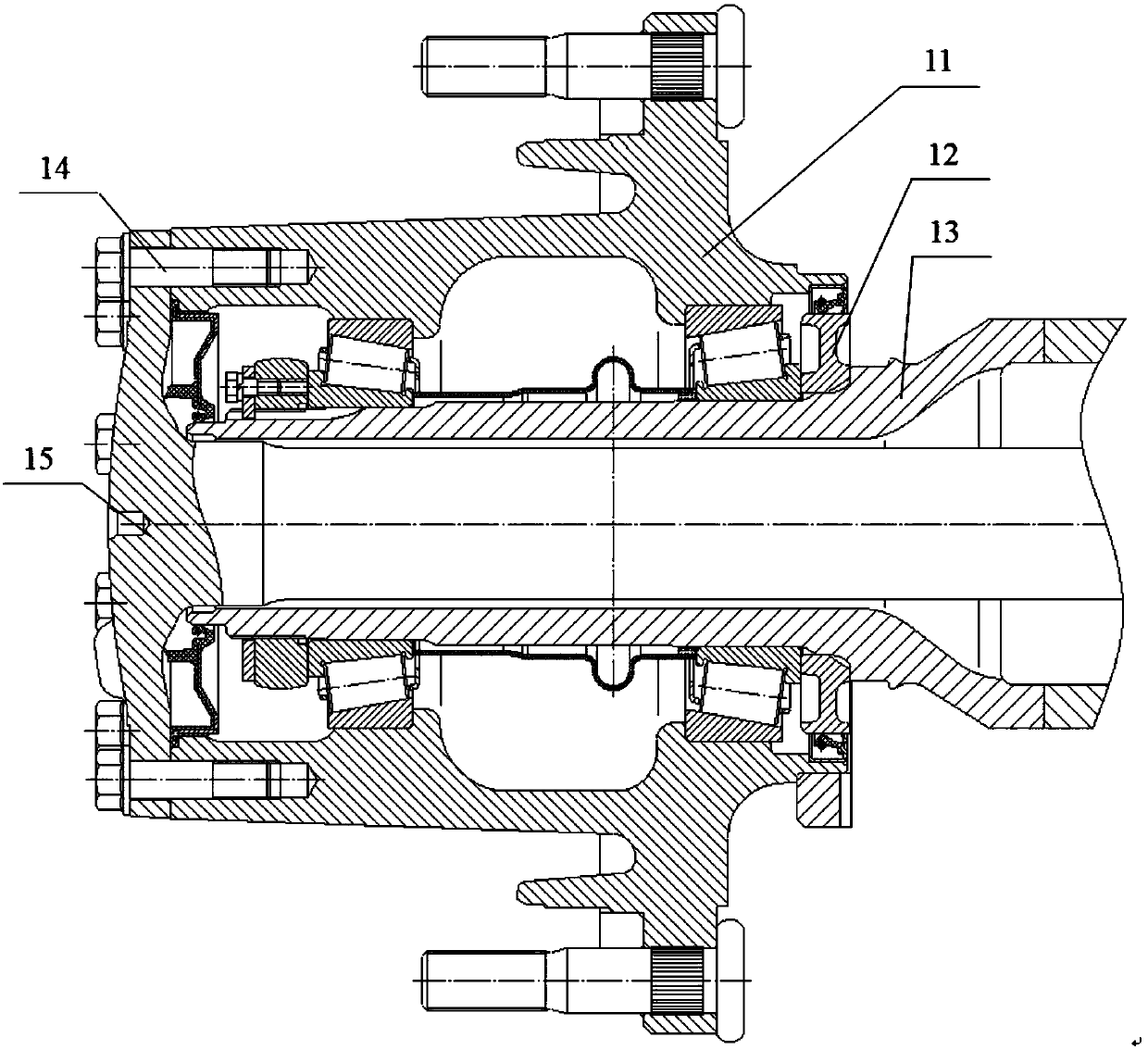

[0029] A commercial vehicle long oil change hub assembly and an assembly method thereof according to the present invention will be described below in conjunction with the accompanying drawings.

[0030] as attached figure 1 As shown, a long oil change hub assembly for a commercial vehicle of the present invention is composed of a tire bolt 1, a high-performance wear-resistant hub inner oil seal 2, a hub inner bearing assembly 3, a hub 4, a wave spacer 5, a hub The outer bearing assembly 6, the shaft nut 7, the shaft nut locking plate 8, the combination bolt 9, and the high-performance wear-resistant hub outer oil seal 10 are composed. A wave spacer 5 is provided between the wheel hub outer bearing inner ring roller assembly 6-1 and the wheel hub inner bearing inner ring roller assembly 3-1. The corrugated spacer 5 is composed of a straight wall part 5-1 and a corrugated part 5-2. The corrugated part 5-2 is shaped like a normal distribution figure that bulges outwards. The cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com