That is, as shown in the model diagram of the new Aide Maru in Non-

Patent Document 1, since it is necessary to have a partition for the

internal combustion engine at the

stern, at the same time, it is necessary to bury the sail control mechanism in the center of the ship for other wind propulsion mechanisms. As well as the sail on the deck of the bow and its under deck, not only the additional cost of

purchasing the original equipment for sailing, but also the sailing equipment also affects the overall structure of the ship. In combination, the manufacturing cost and development cost inevitable rise

And also produce the following problems, sailing equipment brings the following negative effects

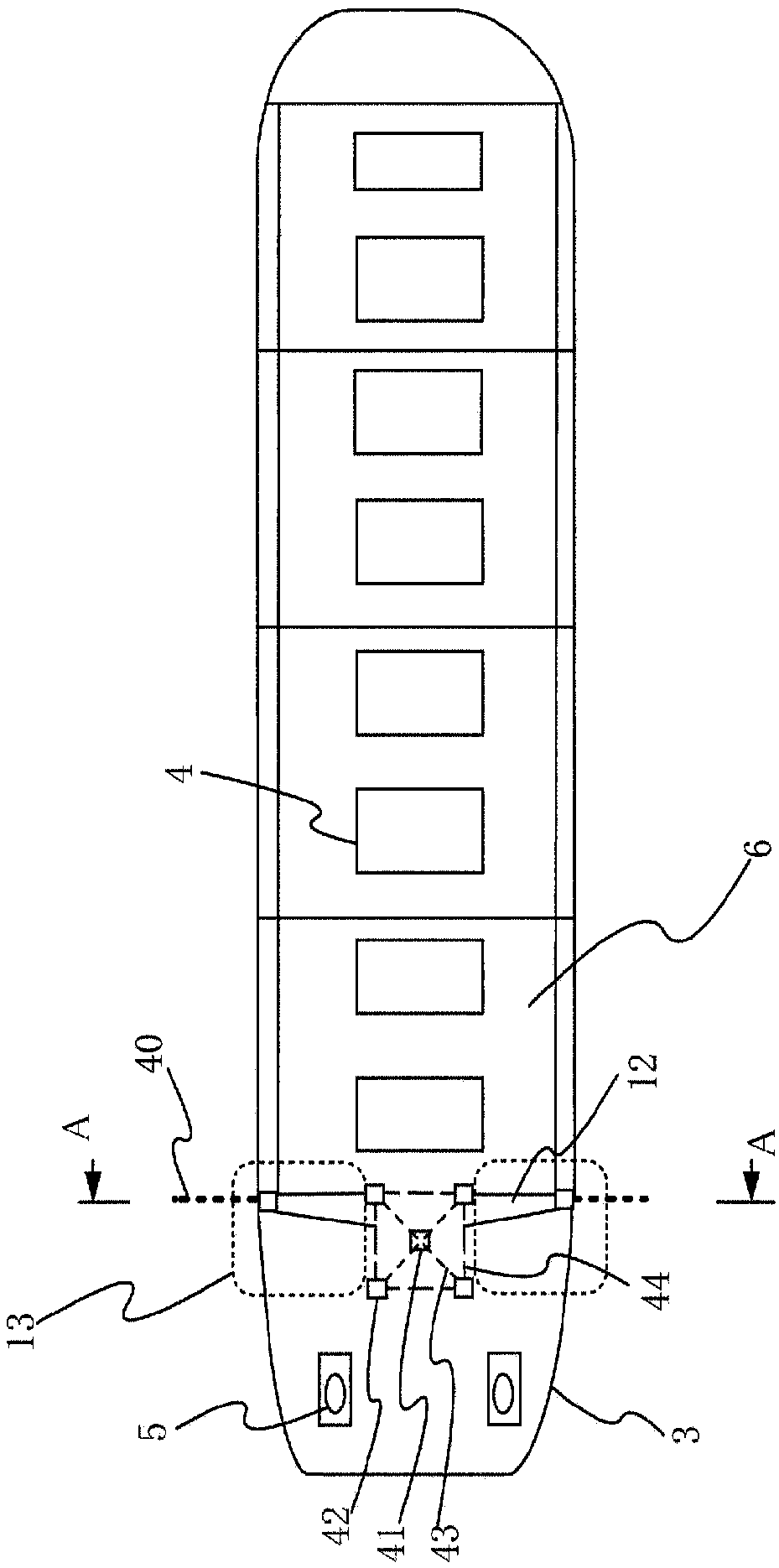

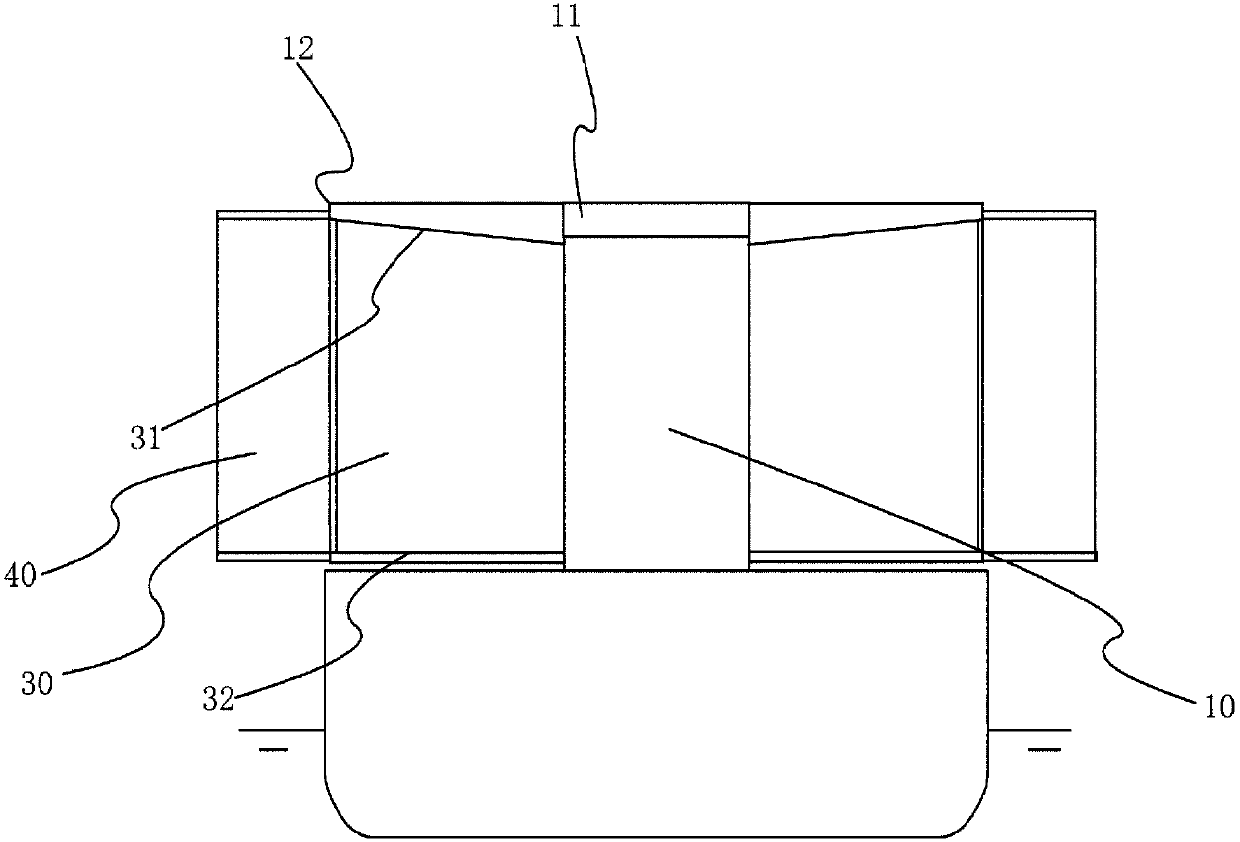

[0008] That is, the method of installing a plurality of sail masts on the deck and placing their supporting structures below the deck not only leads to an increase in manufacturing cost, but also causes the following fundamental problems as a

merchant ship: the sails occupying the space on the deck The opening of unloading is restricted by driving equipment, which hinders the loading and unloading operation of unloading, which in turn increases the time and cost of loading and unloading operations

Since the goal is to take the sail as the main part and the engine as the supplement, the area of the sail increases and the burden on its operation increases. Therefore, as disclosed in

Patent Document 1, it is conceivable to set the sail as a hard wing and make the mast is characterized by flexibility and focuses on reducing operational burdens, but if evaluated as a merchant vessel, the above problems described in

paragraph 0008 also exist

[0011] That is, the following fundamental problem as a

merchant ship still occurs: the masts of a plurality of sails are arranged on the board and the supporting structure thereof is arranged below the deck, which not only leads to an increase in manufacturing cost, but also increases the production cost due to the space occupied on the deck. The opening of the unloading is restricted by sailing the equipment, which becomes an obstacle to the loading and unloading operation of unloading, and additionally generates time and cost for loading and unloading

[0012] In addition, the following problems remain the same: not only the cargo loading space installed on the upper part of the ship is occupied by the sailing equipment, but also the cargo capacity in the ship is reduced due to the installation of auxiliary equipment for sailing below the deck. will decrease

If the amount of cargo carried decreases, the fuel cost per unit of loading will increase, so it is conceivable that even if the fuel cost per unit of the

hull decreases, the consumption of fuel per unit of loaded cargo and handling costs will increase. The result is that, likewise, even if the consumption of fuel is halved, it will not work for merchant ships

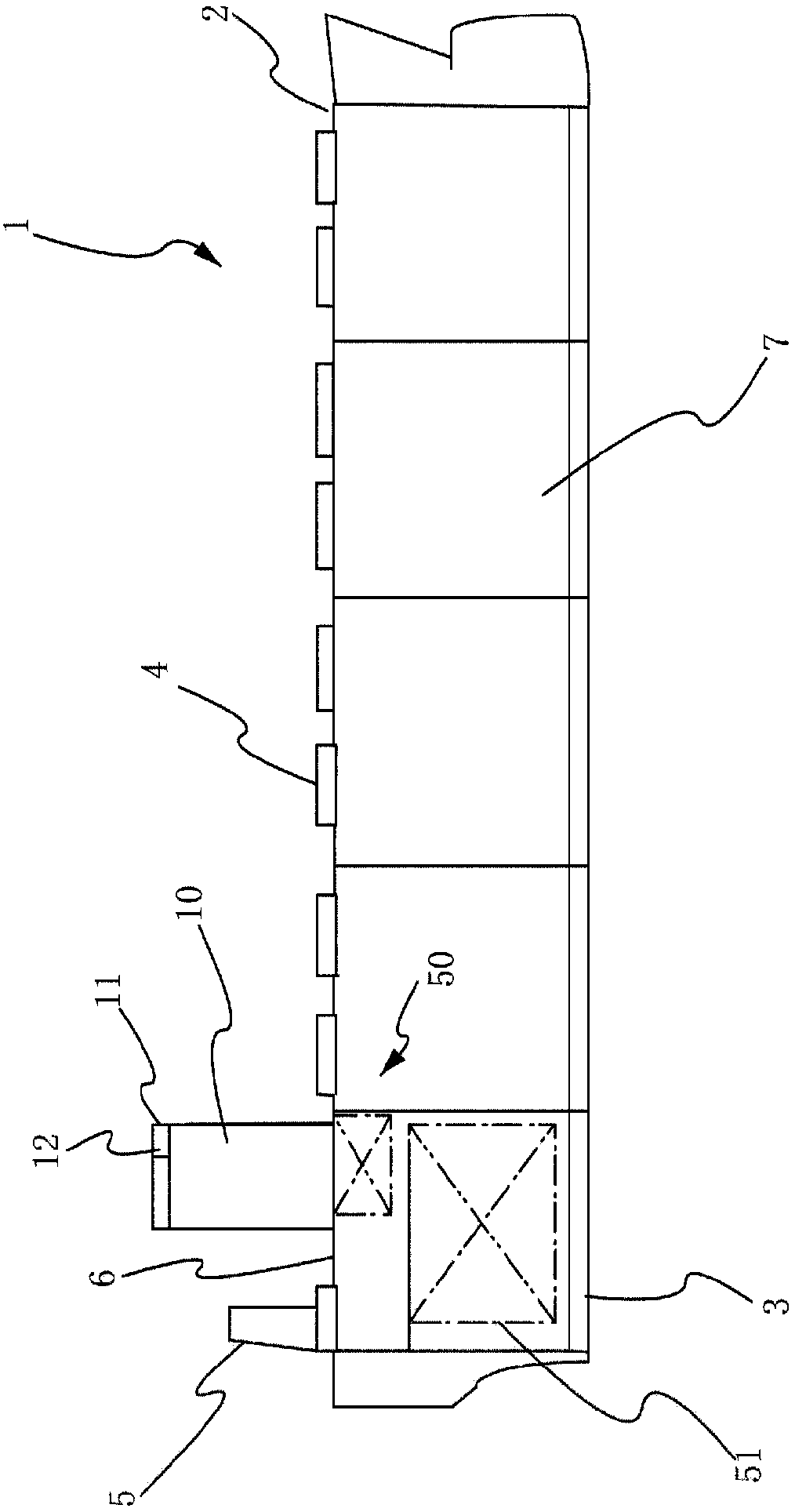

[0013] In addition, since the purpose is a

hybrid sailboat in which the sail is the main part and the engine is the supplementary form, if viewed from the stern, there are more than three huge telescopic sailboats with a width of, for example, 20m and a height of 50m when sailing. (Refer to Figure 7 of the full-

scale model of Non-

Patent Document 2), if viewed from the stern, it will hinder the forward view, so the following problems will also be added: it is different from the Japanese Industrial Standard JIS shown in Non-Patent Document 3 F0420: 2009 (ISO8468: 2007) "Ship and Ocean Technology - Bridge Configuration and Associated Devices - Requirements and Guidelines" are inconsistent

If the bridge is installed at the bow of the ship, a new

dead space may be created in the lower part, and even if the space can be used, the use of merchant ships will be limited, or the load during loading and unloading will increase.

[0016] In addition, it is also known that, in the case of adopting a separate living quarters, it is necessary to additionally install the launching equipment of the lifeboat that is usually arranged at the stern at the bow, which leads to further design changes and restrictions on deck design (Non-Patent Document 4 )

[0017] If the bridge is not arranged at the bow, as disclosed in Fig. 1 of Patent Document 2, a plurality of lower-level sails are set on the deck in order to ensure the front view, but the problem of deck occupation is not solved. It is conceivable that there is still the problem of restricted vision when sailing

Login to View More

Login to View More  Login to View More

Login to View More