A kind of automatic stripping and recycling equipment for waste cables

A technology for waste cables and recycling equipment, which is applied in the direction of dismantling/armored cable equipment, etc., which can solve the problems of low equipment automation, narrow application range, poor compatibility, etc., and achieve cost saving, high automation, and comprehensive functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

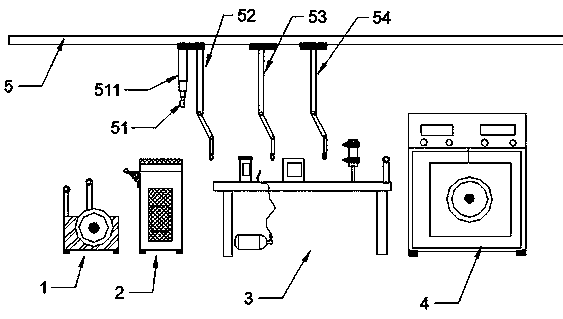

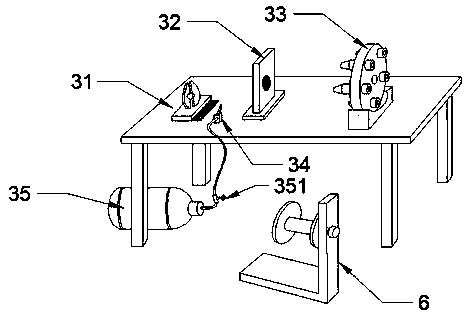

[0031] Such as Figure 1-7 As shown, an automatic stripping and recycling equipment for waste and old cables, including a wire releasing device 1 and a wire taking device 4, a cable straightening device 2 is installed at the rear end of the wire releasing device 1, and a wire stripping work is arranged at the rear end of the cable straightening device 2 Table 3, the rear end of the stripping workbench 3 is the wire take-up device 4, and the movable track 5 is set directly above the position where the cable straightening device 2 and the wire stripping workbench 3 are connected.

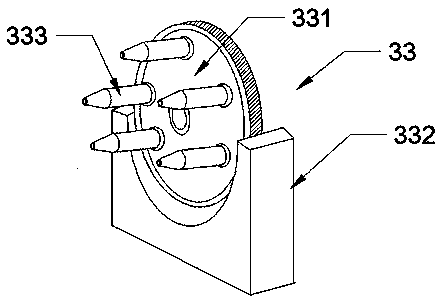

[0032] Stripping workbench 3 surfaces are provided with ring stripping cutter head 31 successively along straight line, peeling cutter 32 and pee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com