Efficient air pressure detection device

An air pressure detection and high-efficiency technology, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of relying on the technical proficiency of sampling personnel and the hidden dangers of measurement accuracy, so as to achieve strong economic practicability, ensure accuracy, The effect of eliminating the loss of light components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

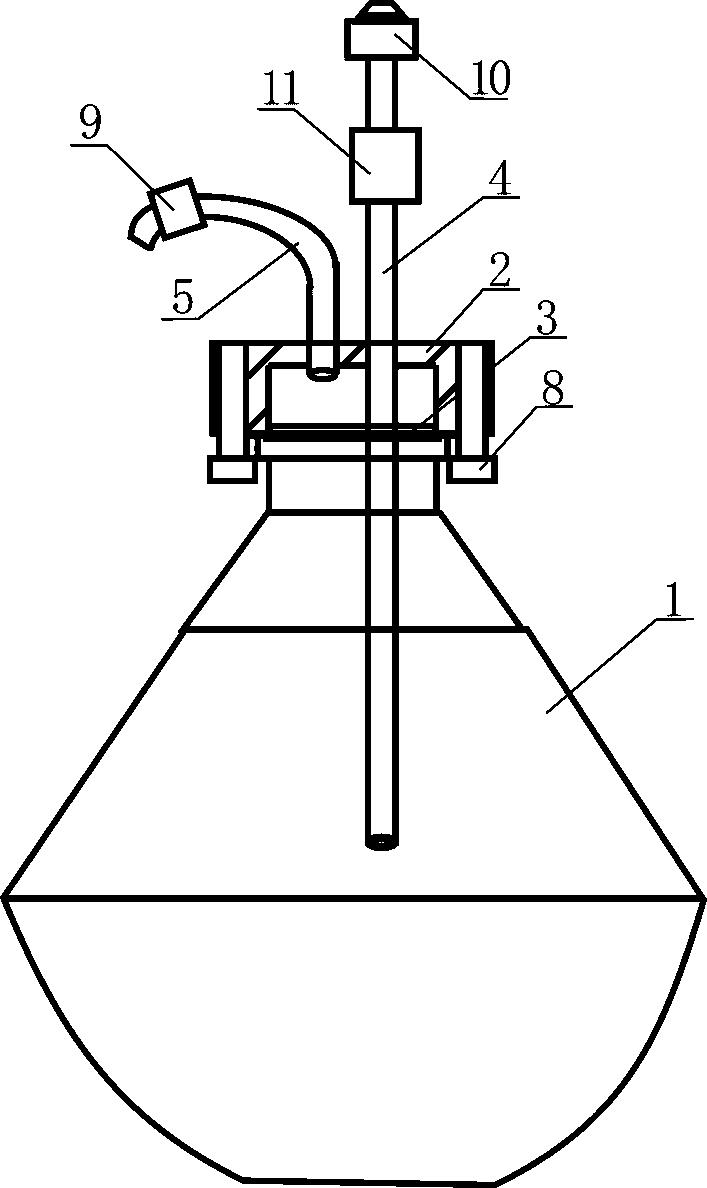

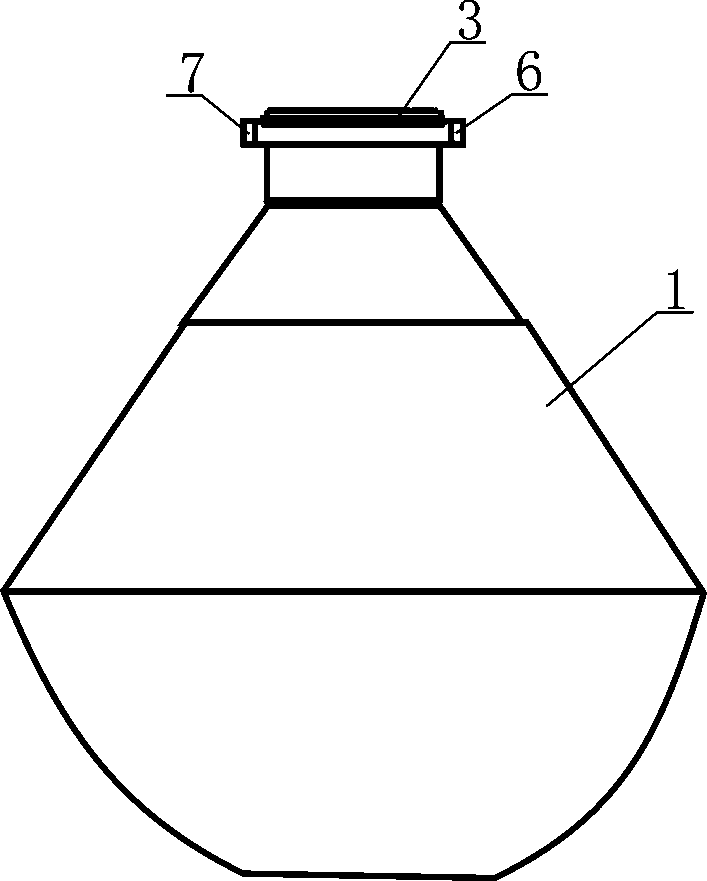

[0011] Such as figure 1 , 2 As shown, the high-efficiency air pressure detection device is mainly composed of air pressure introduction bottle 1, bottle cap 2, sealing rubber ring 3, air pressure introduction pipe 4 and air pressure outlet pipe 5. The port of the air pressure introduction bottle 1 is provided with an outward An extended flange 6, two grooves 7 are distributed along the circumferential direction on the side of the flange 6, screw holes are arranged on the end surface of the bottle cap 2, and fixing bolts 8 are arranged in the screw holes, and the bottle cap 2 is capped on the port of the air pressure introduction bottle 1, and the fixing bolt 8 is located in the groove 7. Tighten the fixing bolt 8 to fix the bottle cap 2 on the air pressure introduction bottle 1, and the sealing rubber ring 3 is set on the bottle cap 2 and the air pressure introduction bottle. Between the ports of the bottle 1, one end of the air pressure inlet tube 4 and the air pressure outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com