One-way valve

A technology for one-way valves and valve chambers, applied in control valves, safety valves, balance valves, etc., can solve problems affecting the control accuracy of the valve body, spring elastic attenuation, etc., achieve flexible use, long service life, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

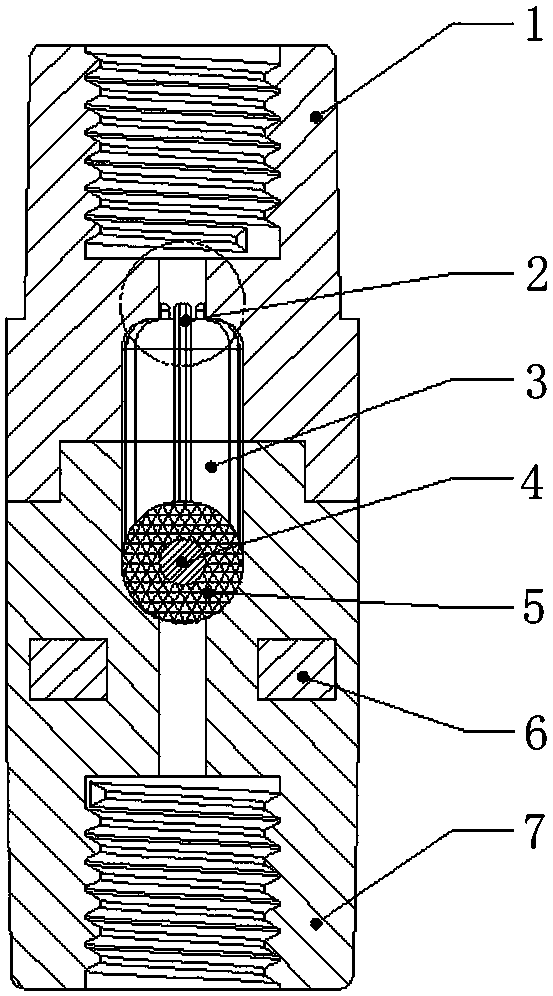

[0023] In order to further clarify the technical scheme and working principle of the present invention, the invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

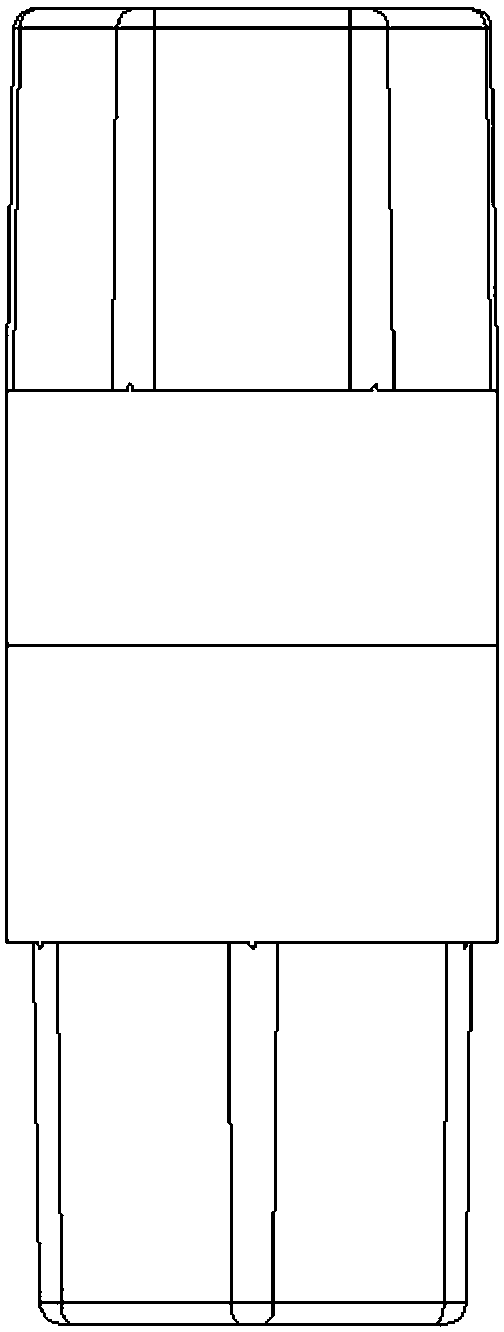

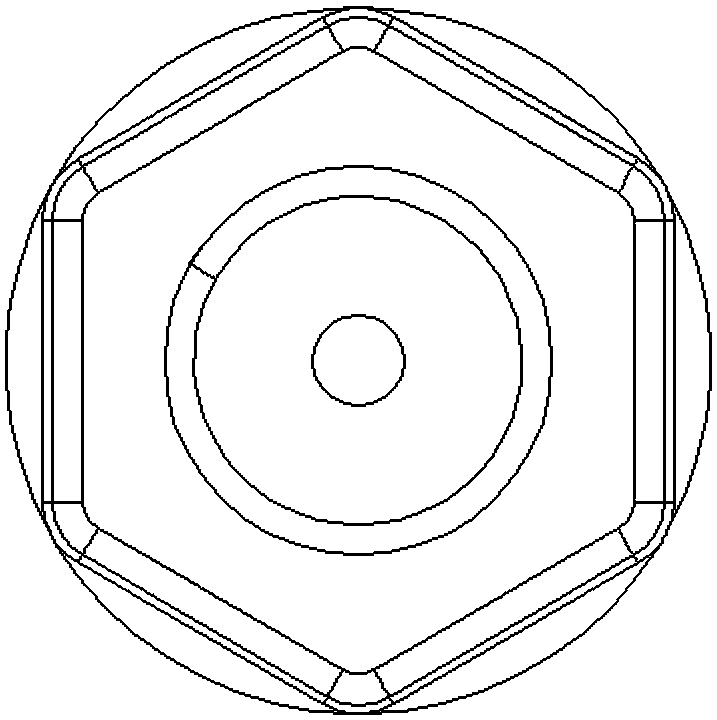

[0024] Such as Figure 1 to Figure 6 A novel one-way valve shown is composed of a housing 1, a plug, and a permanent magnet 6 for controlling the automatic reset of the plug.

[0025] A valve chamber is provided in the housing 1, and a plug is installed in the valve chamber. The housing 1 is preferably made of a non-magnetic material, such as plastic.

[0026] The valve cavity is composed of a main flow channel 3 and an overflow groove 2, such as image 3 , Figure 4 and Figure 6 As shown, the middle part of the main body flow channel 3 is a cylindrical flow channel, and the two ends of the cylindrical flow channel are convex arc-shaped concave grooves. The hemispherical shape with the same flow path diameter makes the longitudinal section of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com