Method for extracting electrolytes from carbon residues in smelting manner

An electrolyte and electrolyte liquid technology, applied in the field of electrolytic aluminum, can solve the problem of undisposable hazardous solid waste of electrolytic aluminum, and achieve the effects of ensuring safety and reliability, reducing investment and avoiding dust generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

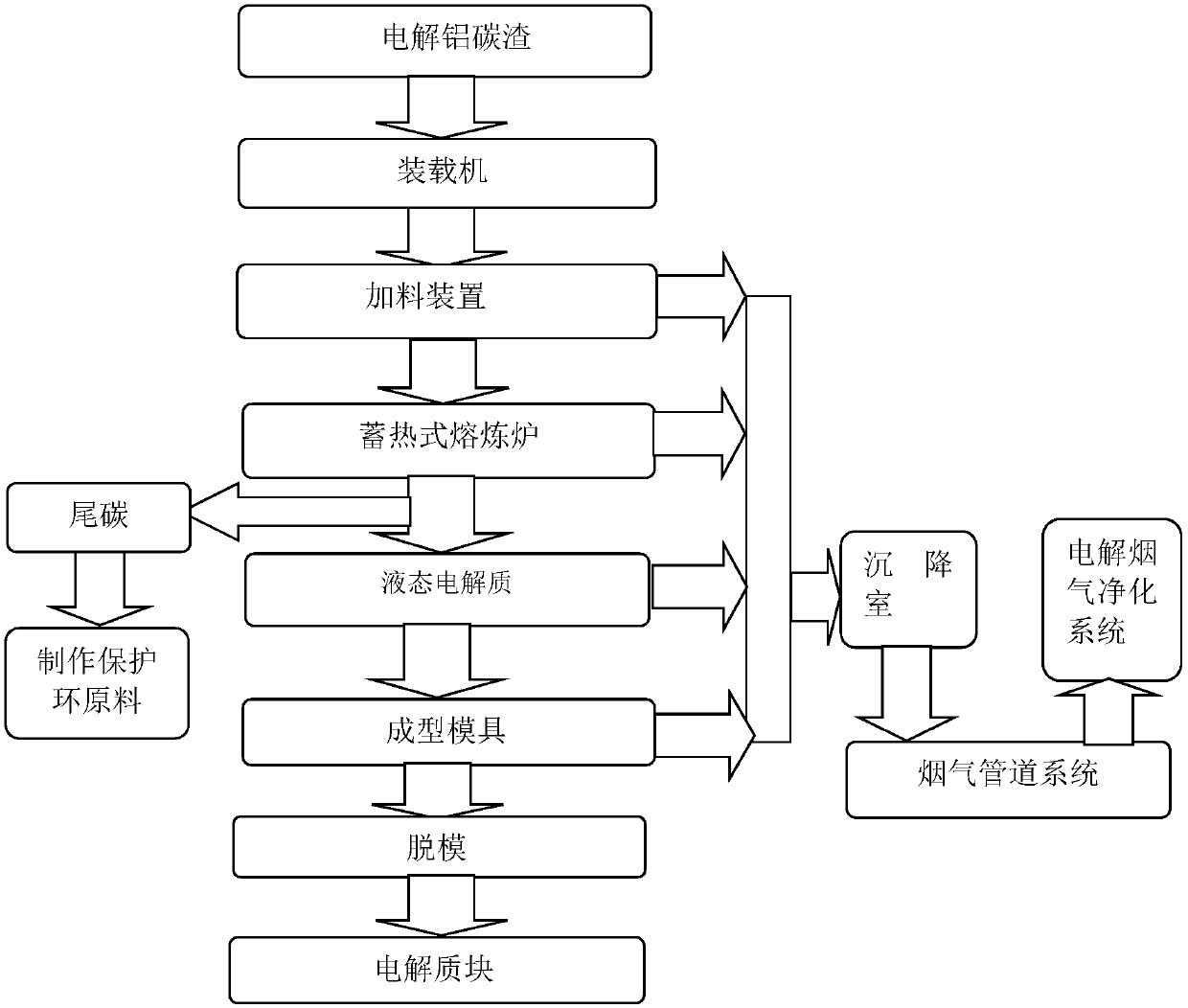

[0028]A smelting method to extract the electrolyte in the carbon slag, the specific process is as follows:

[0029] Put the carbon slag into the feeding device through the loader, then add it to the regenerative melting furnace and heat the carbon slag to 1250°C with natural gas in the regenerative melting furnace. After the electrolyte in the carbon slag is smelted into a liquid state, the carbon floats in the electrolyte liquid On the surface, remove the floating carbon and release the electrolyte into the forming mold to cool and demould to obtain an electrolyte block, which is returned to the production of electrolytic aluminum for use. During the smelting process, the carbon undergoes a combustion reaction, in which about 20% of the carbon is burned, and the remaining carbon can be used as the raw material for the electrolytic aluminum anode steel claw protection ring, so as to realize the recycling of hazardous solid waste in the factory and eliminate Generation of secon...

Embodiment 2

[0031] A smelting method to extract the electrolyte in the carbon slag, the specific process is as follows:

[0032] Put the carbon slag into the feeding device through the loader, then add it to the regenerative melting furnace and heat the carbon slag to 1300°C with natural gas in the regenerative melting furnace. After the electrolyte in the carbon slag is smelted into a liquid state, the carbon floats in the electrolyte liquid On the surface, remove the floating carbon and release the electrolyte into the forming mold to cool and demould to obtain an electrolyte block, which is returned to the production of electrolytic aluminum for use. During the smelting process, the carbon undergoes a combustion reaction, in which about 30% of the carbon is burned, and the remaining carbon can be used as the raw material for the electrolytic aluminum anode steel claw protection ring, so as to realize the recycling of hazardous solid waste in the factory and eliminate Generation of seco...

Embodiment 3

[0034] A smelting method to extract the electrolyte in the carbon slag, the specific process is as follows:

[0035] Put the carbon slag into the feeding device through the loader, then add it to the regenerative melting furnace and heat the carbon slag to 1265°C with natural gas in the regenerative melting furnace. After the electrolyte in the carbon slag is smelted into a liquid state, the carbon floats in the electrolyte liquid On the surface, remove the floating carbon and release the electrolyte into the forming mold to cool and demould to obtain an electrolyte block, which is returned to the production of electrolytic aluminum for use. During the smelting process, carbon undergoes a combustion reaction, in which about 23% of the carbon is burned, and the remaining carbon can be used as the raw material for the electrolytic aluminum anode steel claw protection ring, so as to realize the recycling of hazardous solid waste in the factory and eliminate Generation of secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com