A kind of 9ni marine cryogenic container steel plate with high flaw detection quality and its manufacturing method

A low-temperature container and steel plate technology, which is applied in the field of container steel plates, can solve the problems of long process time and high cost, and achieve the effects of good surface quality, excellent tensile properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

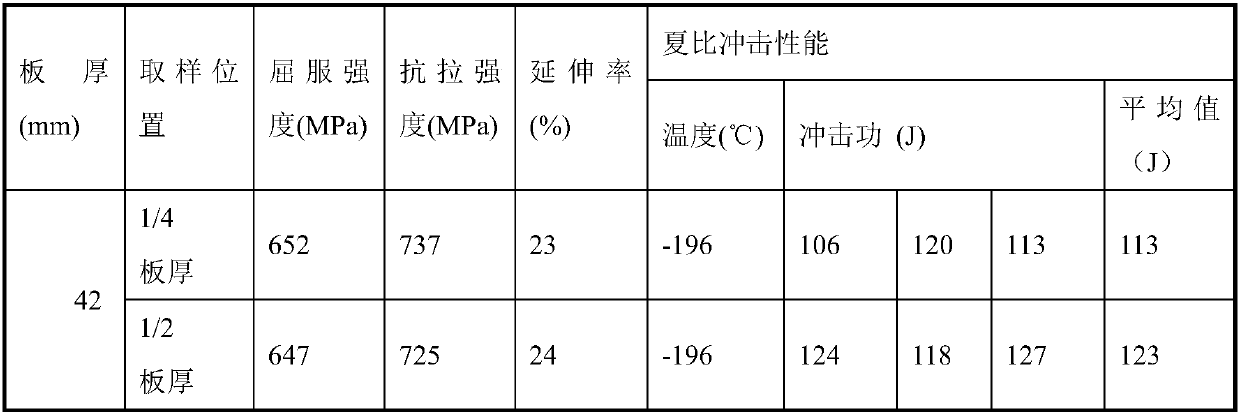

Embodiment 1

[0040] The thickness of the 9Ni marine low-temperature container steel plate involved in this embodiment is 42 mm, and the components and their mass percentages are: C: 0.04%, Si: 0.13%, Mn: 0.75%, P: 005%, S: 0.001%, Cr : 0.12%, Mo: 0.05%, Ni: 9.2%, Cu: 0.25%, Alt: 0.029%, Nb: 0.013%, N: 40ppm, the balance is iron and unavoidable impurity elements, carbon equivalent CEV (=C +Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15))=0.78.

[0041] The production process of the marine cryogenic container steel plate is as follows:

[0042] According to the chemical composition of the above-mentioned 9Ni marine low-temperature container steel plate, the smelting raw materials are arranged in order to carry out BOF smelting-RH refining-LF refining-RH refining-slab continuous casting-slow cooling pit slow cooling-slab heating-high pressure water descaling-slab rolling System-heating-controlled rolling-straightening-slow cooling-twice quenching-tempering.

[0043] Select high-quality pig iron and steel plat...

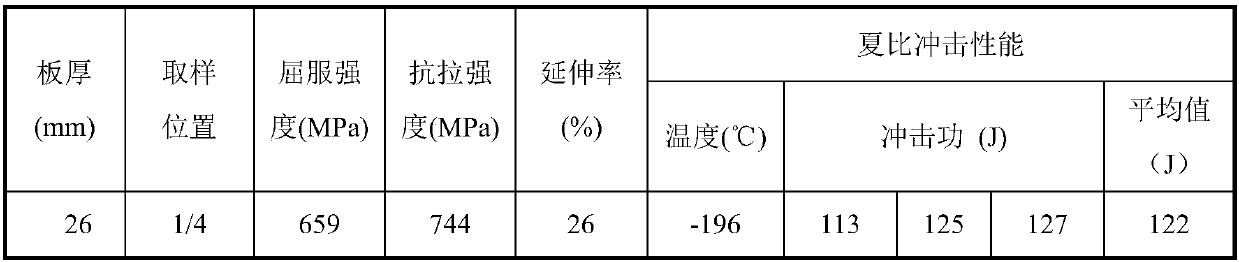

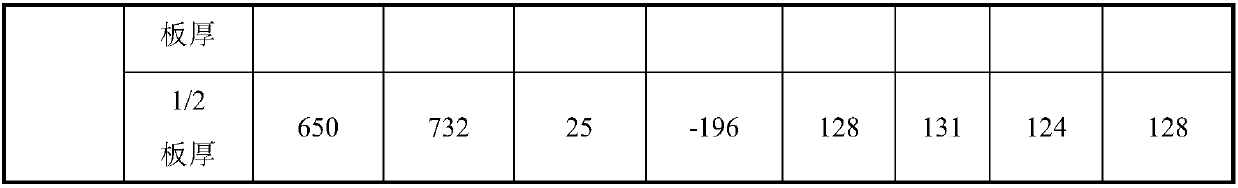

Embodiment 2

[0053] The thickness of the 9Ni marine low-temperature container steel plate involved in this embodiment is 26mm, and the components and their mass percentages are: C: 0.035%, Si: 0.12%, Mn: 0.77%, P: 005%, S: 0.001%, Cr : 0.12%, Mo: 0.05%, Ni: 9.2%, Cu: 0.25%, Alt: 0.029%, Nb: 0.013%, N: 40ppm, the balance is iron and unavoidable impurity elements, carbon equivalent CEV (=C +Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15))=0.77.

[0054] The production process of the marine cryogenic container steel plate is as follows:

[0055] According to the chemical composition of the above-mentioned 9Ni marine low-temperature container steel plate, the smelting raw materials are arranged in order to carry out BOF smelting-RH refining-LF refining-RH refining-slab continuous casting-slow cooling pit slow cooling-slab heating-high pressure water descaling-slab rolling System-heating-controlled rolling-straightening-slow cooling-twice quenching-tempering.

[0056] Select high-quality pig iron and steel plat...

Embodiment 3

[0067] The thickness of the 9Ni marine low-temperature container steel plate involved in this embodiment is 8mm, and the components and their mass percentages are: C: 0.034%, Si: 0.13%, Mn: 0.74%, P: 005%, S: 0.001%, Cr : 0.12%, Mo: 0.06%, Ni: 9.1%, Cu: 0.25%, Alt: 0.024%, Nb: 0.013%, N: 40ppm, the balance is iron and unavoidable impurity elements, carbon equivalent CEV (=C +Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15))=0.75.

[0068] The production process of the marine cryogenic container steel plate is as follows:

[0069] According to the chemical composition of the above-mentioned 9Ni marine low-temperature container steel plate, the smelting raw materials are arranged in order to carry out BOF smelting-RH refining-LF refining-RH refining-slab continuous casting-slow cooling pit slow cooling-slab heating-high pressure water descaling-slab rolling System-heating-controlled rolling-straightening-slow cooling-twice quenching-tempering.

[0070] Select high-quality pig iron and steel plate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com