Frog lifting tool

A frog and spreader technology is applied in the field of rail spreaders for high-speed rail construction, which can solve the problems of insufficient compact structure, poor bearing strength, and inability to use frogs for hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

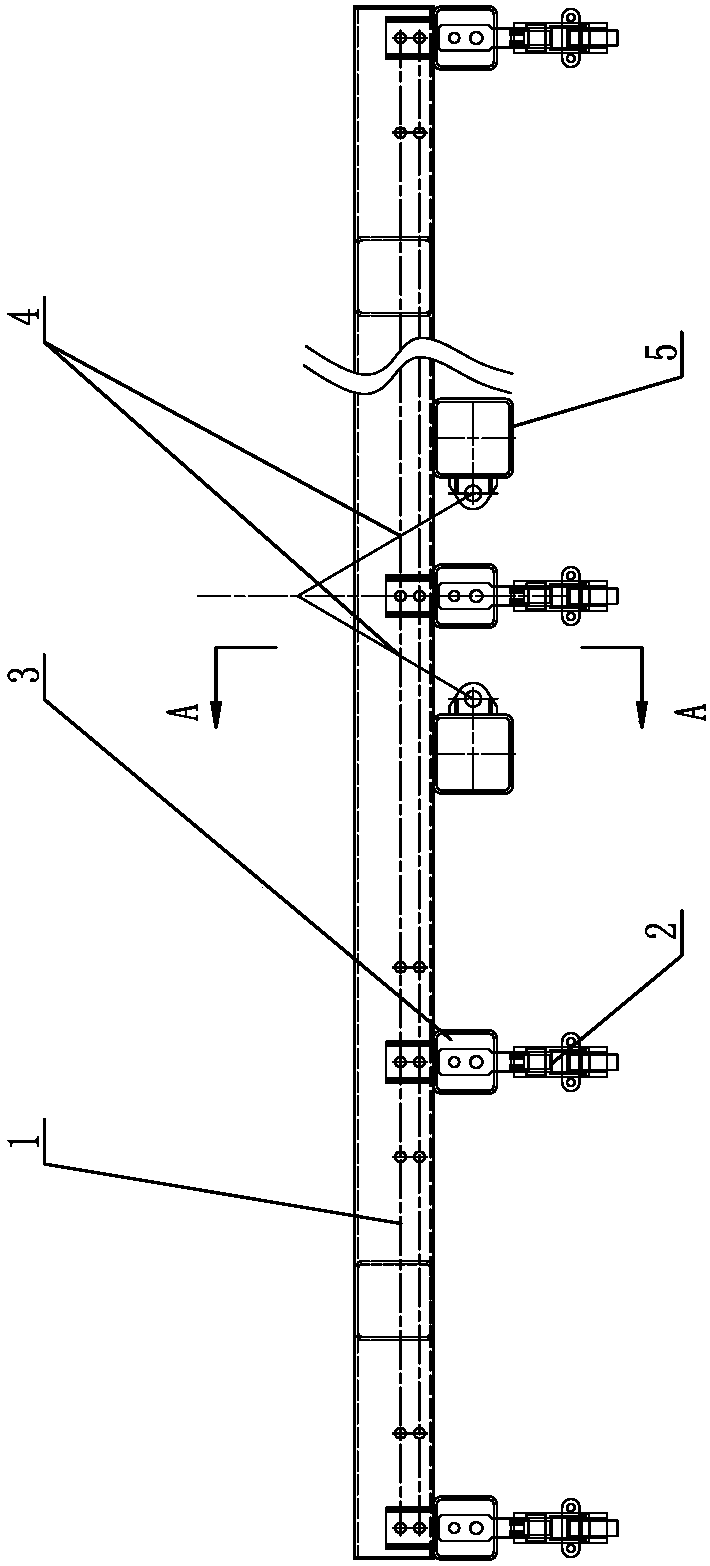

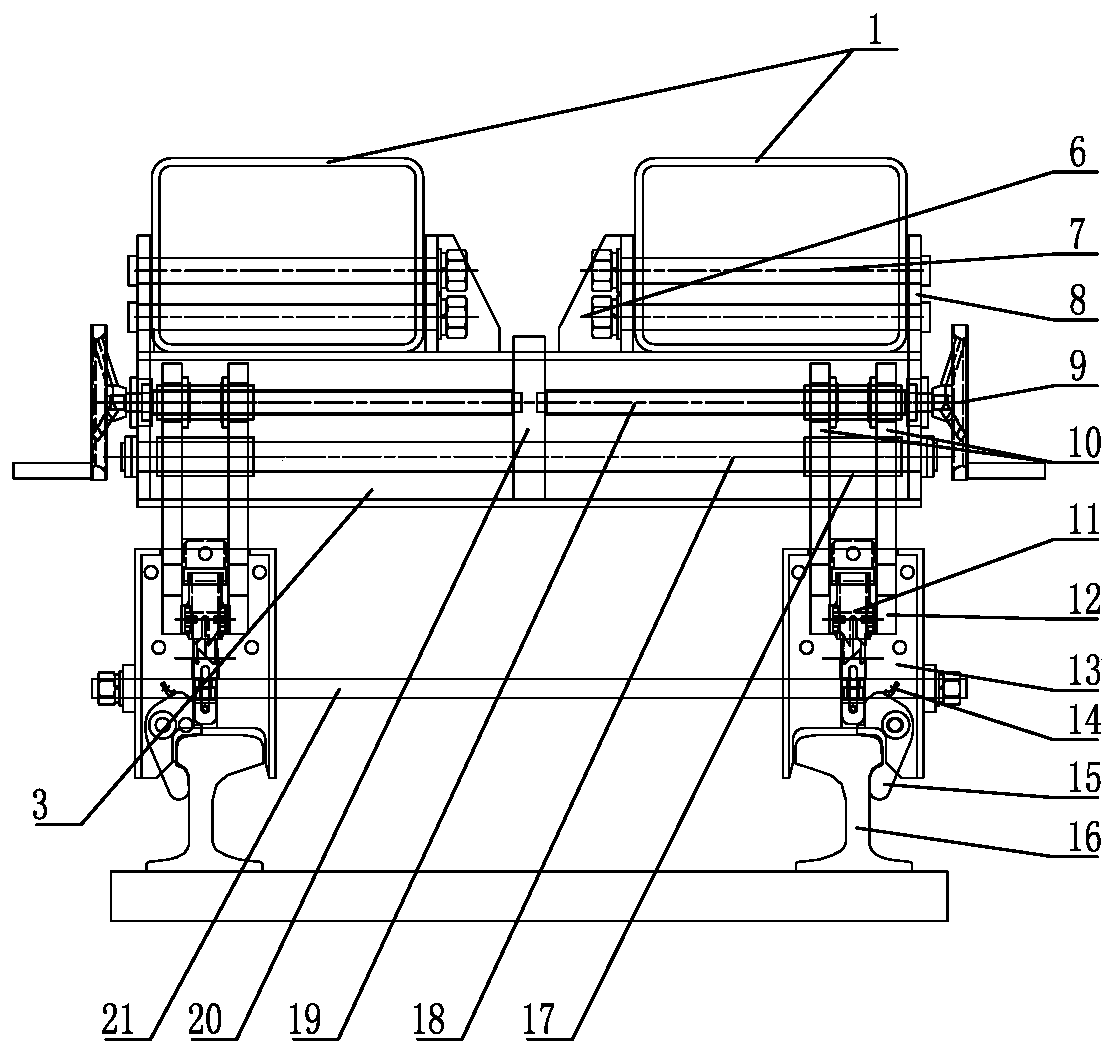

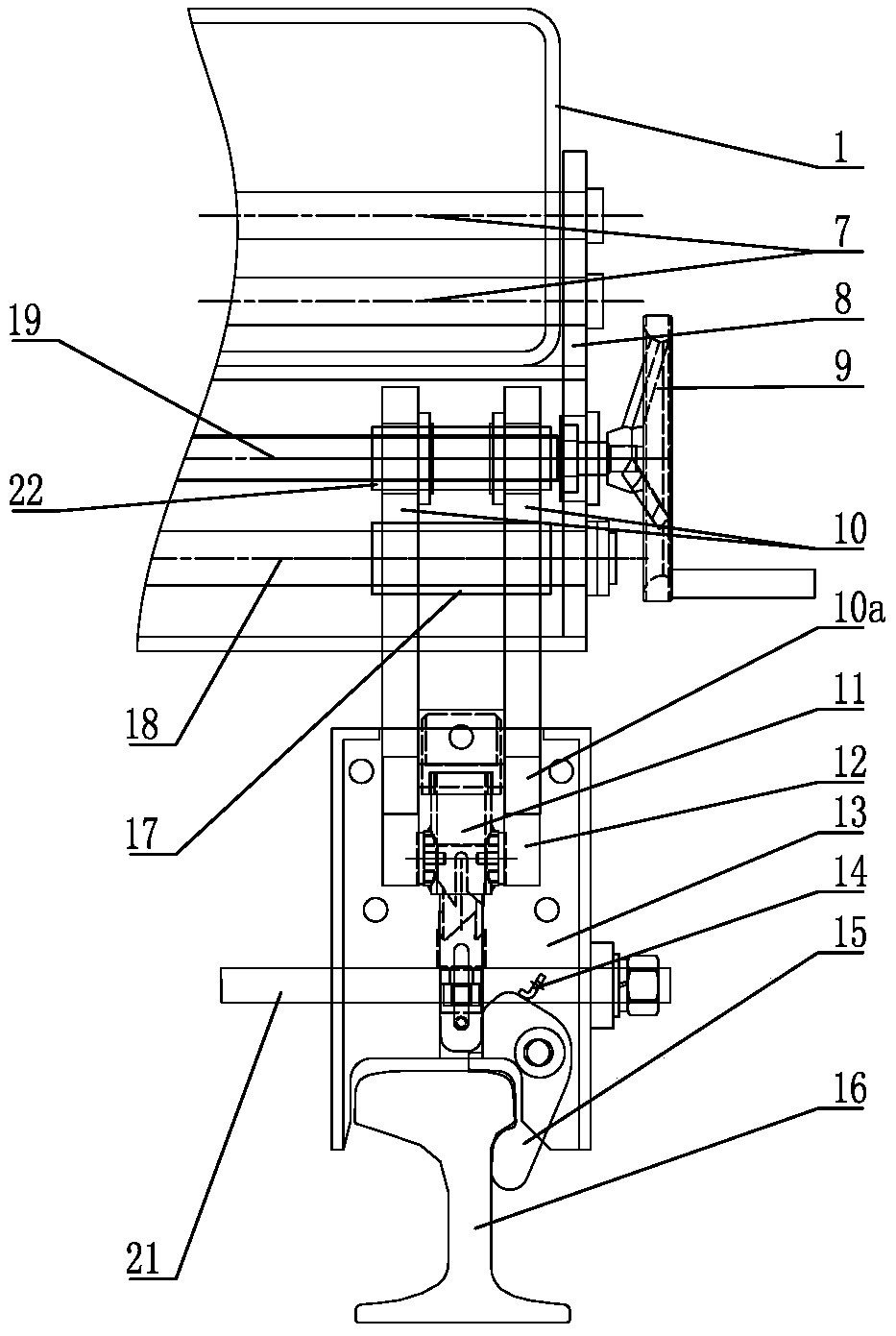

[0023] Such as Figure 1-7As shown, it is a frog spreader. Its structure includes two main hanging beams 1 arranged in parallel. Five auxiliary hanging beams are evenly spaced between the lower sides of the main hanging beams 1. The inner side of the main hanging beam 1 is connected to the The auxiliary hanging beams are connected, the outer side of the main hanging beam 1 is connected with the auxiliary hanging beams through the side plates 8, and the main hanging beam 1, the side plates 8 and the reinforcement plates 6 are fixedly connected by two connecting screws 7 arranged in parallel; There is a slide bar 18, on which two groups of lifting assemblies 2 are arranged symmetrically; each set of lifting assemblies 2 includes a sliding sleeve 17, and the sliding sleeve 17 is connected to two parallel connecting plates 10; the lower end of the connecting plate 10 is provided with The sliding part 10a, the sliding part 10a is slidably installed in the longitudinal chute 12 prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com