Automatic high-efficiency fresh tea leaf classification device

A classification device, tea technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of low degree of automation, small feeding caliber, and feeding speed that cannot be too fast. , to achieve the effect of improving production efficiency, low production cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

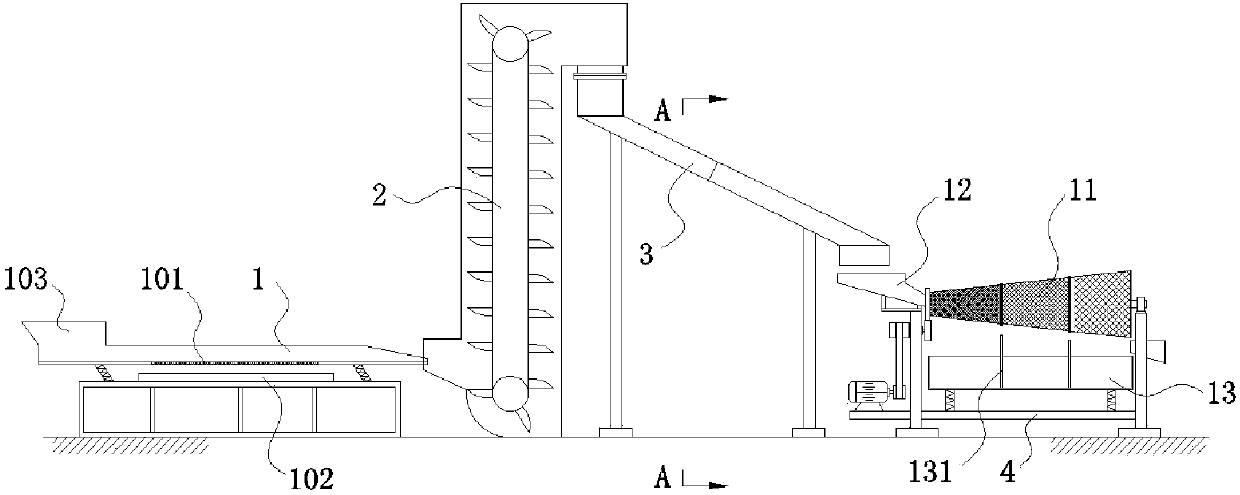

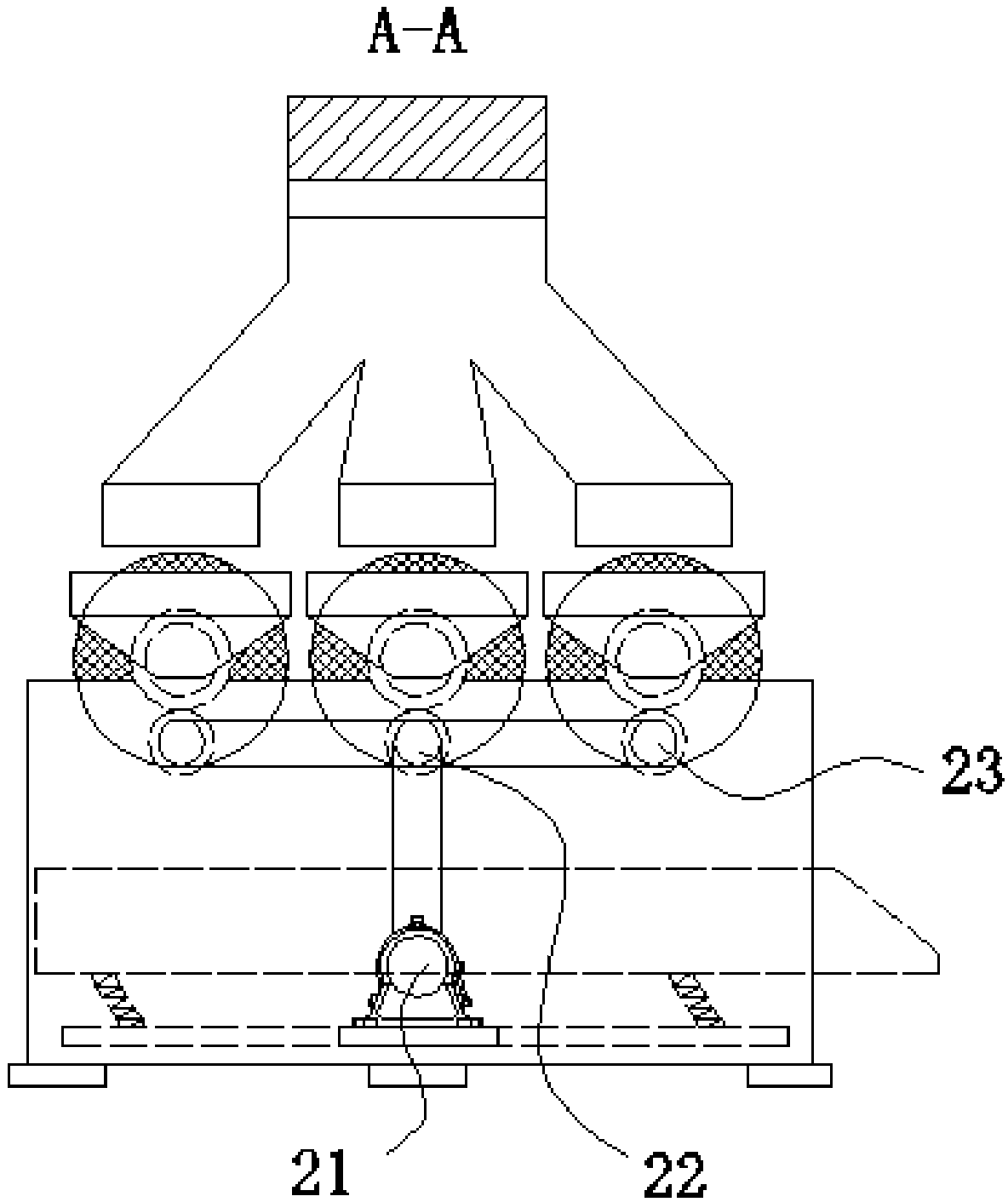

[0013] As shown in the figure: an automatic and high-efficiency tea leaf grading device, including a vibrating conveying trough 1, a tea hoist 2, a conveying chute 3 and a tea classifier 4, the vibrating conveying trough 1 is connected with the tea hoist 2, and the tea leaves are lifted The machine 2 is connected to the conveying chute 3 through a flange, and the tea classifying machine 4 is provided with three netted grading drums 11, and the entrances of the drums are respectively provided with feeding hoppers 12, and the lower part of the conveying chute 3 has three chute outlets, Connected with the feed hopper 12 respectively, the lower part of the tea classifier 4 is provided with an integral vibration discharge classification tank 13, and the vibration discharge classification tank 13 is provided with a partition 131 to form a classificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com