Fine grain dry separator for weakening magnetic effect loss

A technology of dry separation machine and magnetic effect, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc. It can solve the problems of shortening the decay period of the magnetic property of the magnetic system, accelerating the decay of the magnetic property of the magnetic system, and increasing the power loss of the magnetic system. , to reduce power loss, prolong service life and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

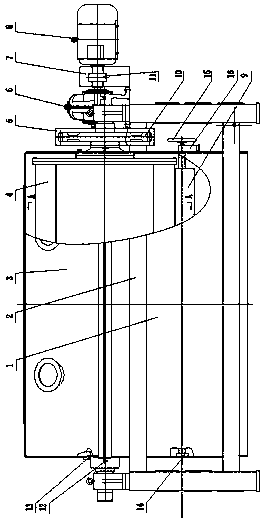

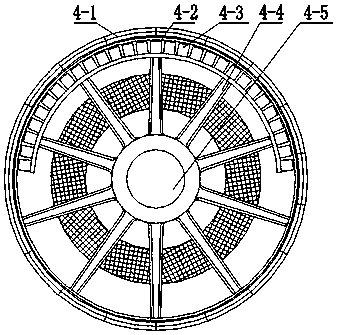

[0014] With reference to accompanying drawing, a kind of fine-grain dry separation machine that weakens magnetic effect loss comprises lower casing 1, frame 2, upper casing 3, permanent magnet cylinder 4, first safety cover 5, speed reducer 6, second Safety cover 7, motor 8, ore unloading adjustment device 9, gear 10, coupling 11, soft rubber seal 12, sealing material seal 13, seat body 14, adjustment handle 15, adjustment plate support 16, lower box body 1 through Bolts are fixed on the frame 2, the shaft seat of the permanent magnet cylinder 4 is arranged on the frame 2 and connected by bolts, the permanent magnet cylinder 4 is arranged in the upper box body 3 and the lower box body 1, and the upper box body 3 and the lower box body The connection of the lower box 1 is sealed with soft rubber 12 and connected with bolts, the contact surfaces of the permanent magnet cylinder 4 and the upper box 3 and the lower box 1 are sealed with a sealing material 13, and one end of the unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com