Electrocatalyst and preparation method thereof

An electrocatalyst and thin film technology, applied in the field of electrocatalyst and its preparation, can solve the problems of inability to meet industrial production requirements, low electrocatalyst activity, low production efficiency, etc., and achieve industrialized large-scale production, stable performance, and adjustable composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

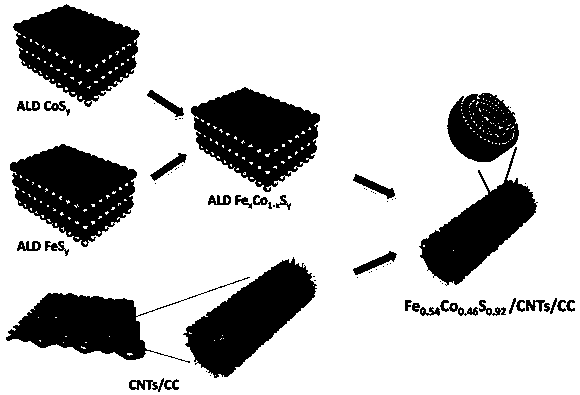

[0054] 1. Combine figure 1 Shown, this embodiment Fe 0.54 co 0.46 S 0.92 / CNTs / CC electrode preparation steps are as follows:

[0055] The carbon cloth was soaked in 0.1M Ni(NO 3 ) 2 Put the dry carbon cloth in the middle of the tube furnace, put 5mL of the mixed solution of ethanol and isopropanol with a volume ratio of 5:1 on the upstream of the tube, pass nitrogen for 20min, and then 20min The temperature was raised to 800°C and maintained for 10 minutes; after the end, it was cooled to room temperature to obtain CNTs / CC.

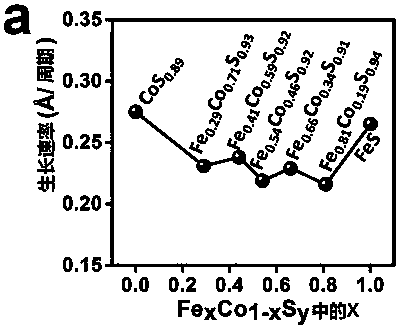

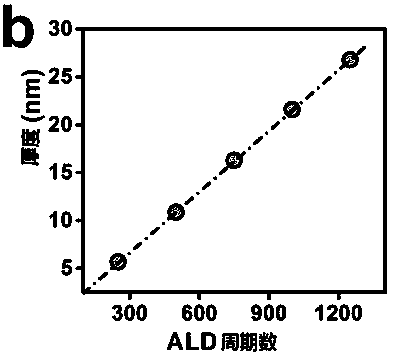

[0056] Put the CNTs / CC substrate into the ALD chamber, set the PE-ALD program, feed high-purity nitrogen, and control the deposition at 250 °C. Heat bis(N,N'-diisopropylacetamidino)cobalt to 75°C, and then mix the heated bis(N,N'-diisopropylacetamidino)cobalt with H 2 S is introduced into the ALD cavity to control bis(N,N'-diisopropylacetamido) cobalt and H 2 The exposure pressure of S is 0.4Torrs and 0.062Torrs respectively, and CoS is deposited ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com