Electric heating film and preparation method and application thereof

An electric heating film and electric heating layer technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of electric heating ink technology, resin aging organic solvents, etc., to improve service performance and process water-based. , the effect of high thermal energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

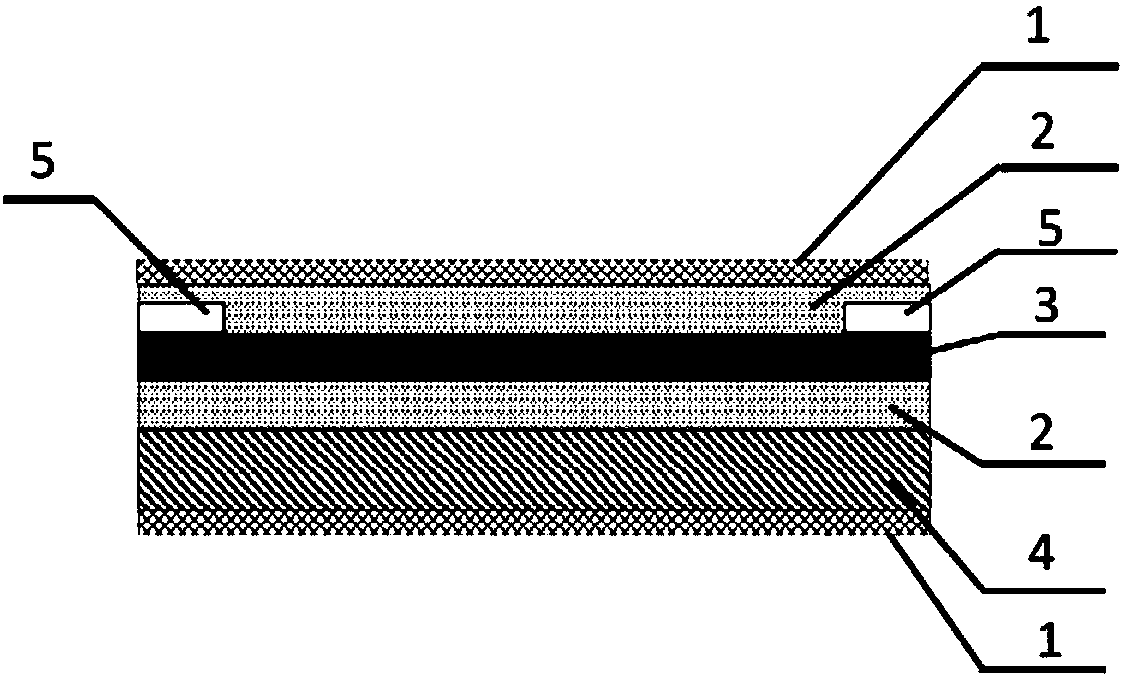

Image

Examples

preparation example Construction

[0031] Specifically, the preparation method includes the following steps:

[0032] (1) Highly conductive nano-carbon material and dispersant are uniformly dispersed in water to form a nano-carbon water-based dispersion liquid. In the nano-carbon water-based dispersion liquid, the content of nano-carbon material is 0.05~10wt%, and the content of dispersant is 0.02~ 5wt%;

[0033] (2) Mix 20-50 parts of hydrophilic resin, 1-10 parts of wetting agent, 1-10 parts of dispersant, 1-8 parts of cosolvent and 50-90 parts of water to form a fabric hydrophilic treatment solution;

[0034] (3) soaking the fiber base fabric with the fabric hydrophilic treatment solution, and then drying at 50-90°C to obtain a hydrophilic fabric;

[0035] (4) soaking the hydrophilic fabric with the nano-carbon aqueous dispersion, and then drying at 50-90° C. to obtain an electric heating layer;

[0036] (5) The electrodes are arranged in the electrothermal layer;

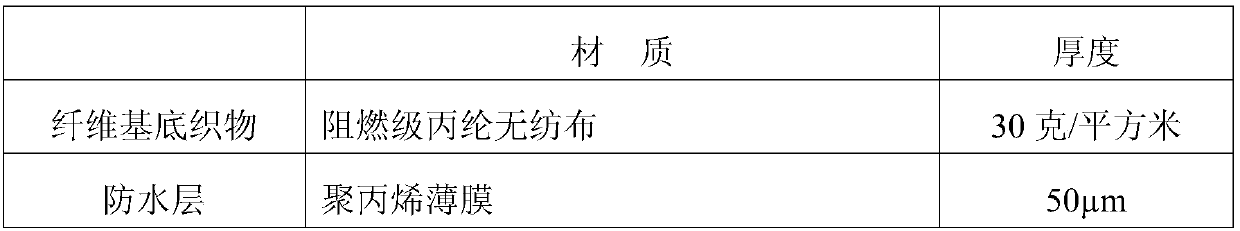

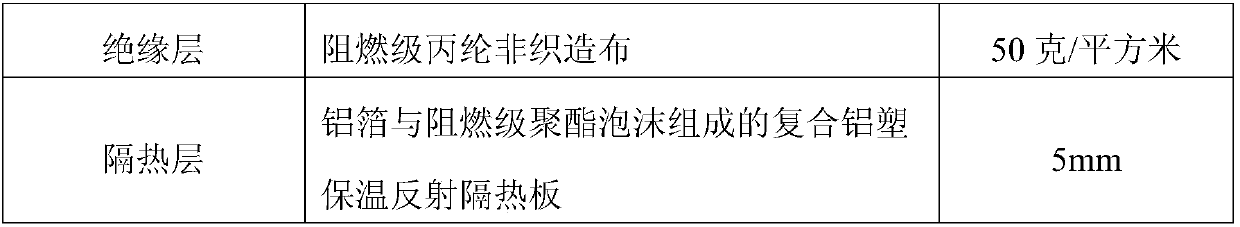

[0037] (6) The waterproof layer, insula...

Embodiment 1

[0079] First, configure the nano-carbon aqueous dispersion, wherein the content of multi-walled carbon nanotubes is 2wt%, the content of sulfate surfactant sodium lauryl sulfate dispersant is 1wt%, and the ultrasonic dispersion process is used to prepare uniformly dispersed nano Carbon water-based dispersion, stand for defoaming and use for later use. At the same time, prepare fabric hydrophilic treatment solution, disperse 30 parts of acrylamide-modified water-based acrylic resin, 2 parts of sodium secondary alkyl sulfonate, 2 parts of anionic surfactant dispersant, 5 parts of ethanol co-solvent, and 61 parts of water in high-speed dispersion Mix evenly under the machine, and set aside for defoaming. Next, the fiber base fabric is dipped into the fabric hydrophilic treatment liquid by dip coating process, and dried at 70° C. to obtain the hydrophilic fabric. Subsequently, the hydrophilic fabric is soaked in the nano-carbon aqueous dispersion by a dip-coating process, and dri...

Embodiment 2

[0084] First, configure the nano-carbon aqueous dispersion, wherein the content of multi-walled carbon nanotubes is 3wt%, the content of polyoxyethylene ether AEO-10P dispersant is 1wt%, and the ultrasonic dispersion process is used to prepare a uniformly dispersed nano-carbon aqueous dispersion , set aside after defoaming. Simultaneously, prepare fabric hydrophilic treatment solution, 20 parts of polyethylene glycol modified water-based acrylic resins, 2 parts of secondary alkylsulfonate sodium, 2 parts of anionic surfactant dispersants, 5 parts of ethanol co-solvents, 61 parts of water in Mix evenly in a high-speed disperser, and set aside for defoaming. Next, the fiber base fabric is dipped into the hydrophilic treatment solution by dip coating process, and dried at 50° C. to obtain the hydrophilic fabric. Subsequently, the hydrophilic fabric is soaked in the nano-carbon aqueous dispersion by a dip-coating process, and dried at 50° C. to obtain an electric heating layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com