Trench gate super-junction MOSFET device and preparation method therefor

A trench gate and trench technology, which is applied in semiconductor/solid state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing on-resistance, increasing on-resistance, reducing device size, etc., achieving compact structure, reducing On-resistance, the effect of improving avalanche resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

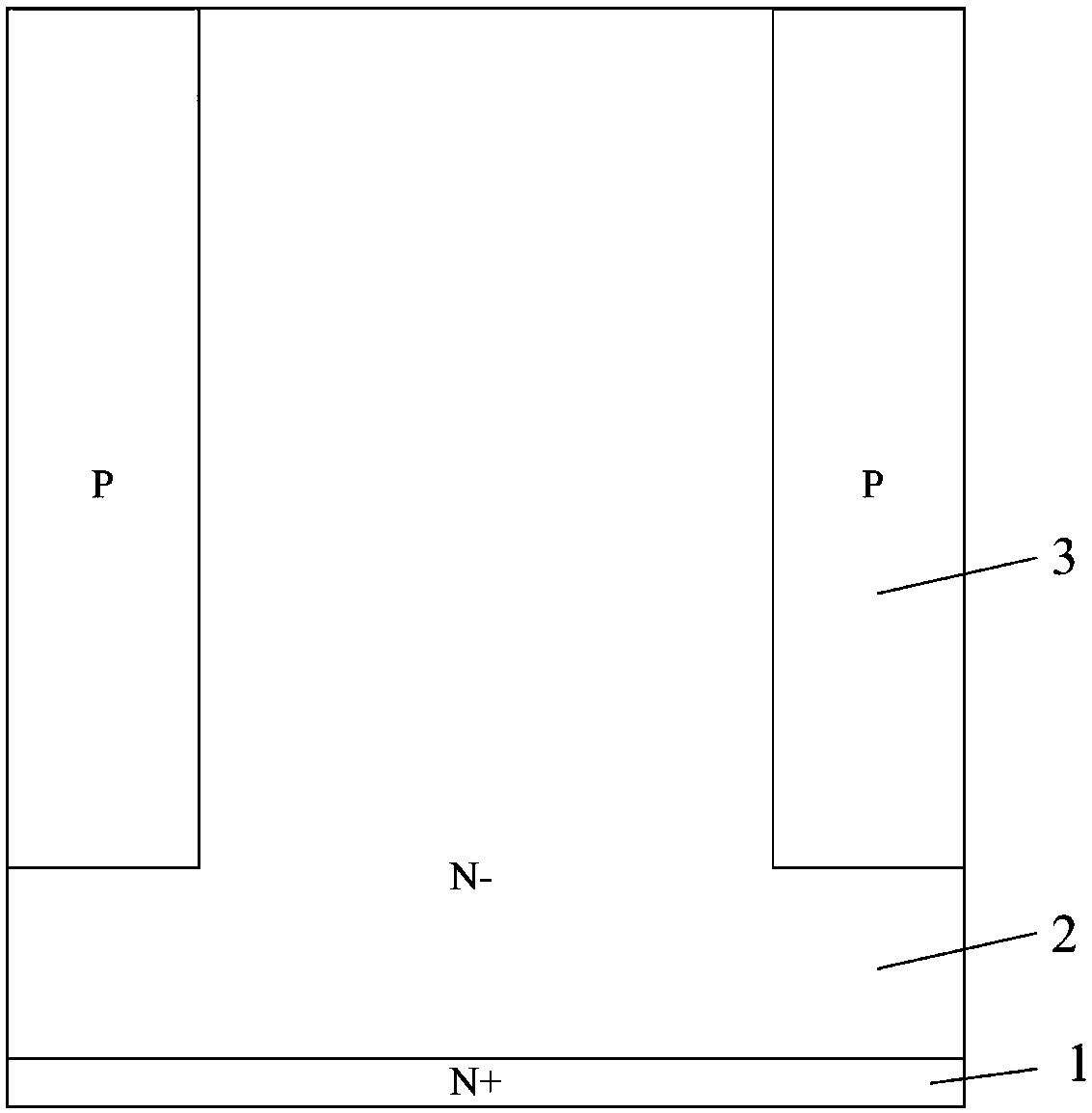

[0037] Such as figure 1 with Picture 9 Shown: In order to effectively reduce the channel resistance and improve the avalanche tolerance, taking the N-type MOSFET device as an example, the present invention includes a semiconductor substrate and a cell area located in the central area of the semiconductor substrate. The semiconductor substrate includes an N+ substrate 1 and a The N-type epitaxial layer 2 above the N+ substrate 1; a super junction structure is arranged in the N-type epitaxial layer 2 in the cell region, and the super junction structure includes a number of alternately distributed N pillars and P pillars 3;

[0038] The P pillar 3 extends vertically downward from the top of the N-type epitaxial layer 2, a cell trench 11 is provided between adjacent P pillars 3, and a P-type base is provided on the outer side and upper side of the cell trench 11 Reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com