In-hole double-plunger water injection infiltration testing apparatus and working method thereof

A technology of water injection test and working method, applied in the field of geotechnical engineering, can solve the problems of unfavorable cost control and environmental protection, difficult water isolation of non-test soil layers, complicated installation of test devices, etc., so as to avoid water penetration risks and control potential risks. , the overall light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

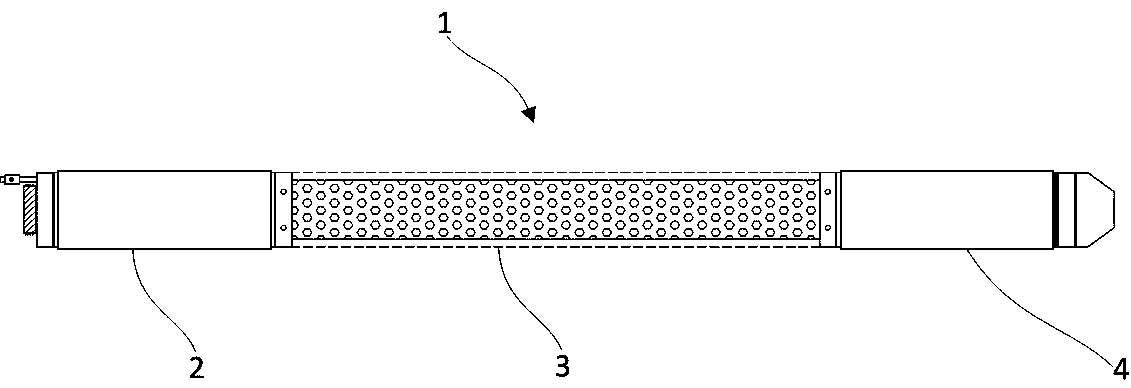

[0029] Example: as figure 1 As shown in the figure, this embodiment specifically relates to an in-hole double-plunger water injection penetration tester. The in-hole dual-plunger water injection penetration tester 1 includes an upper water-stop chamber 2, a water-injection test chamber 3 and a lower stopper that are coaxially connected in sequence. Water chamber 4.

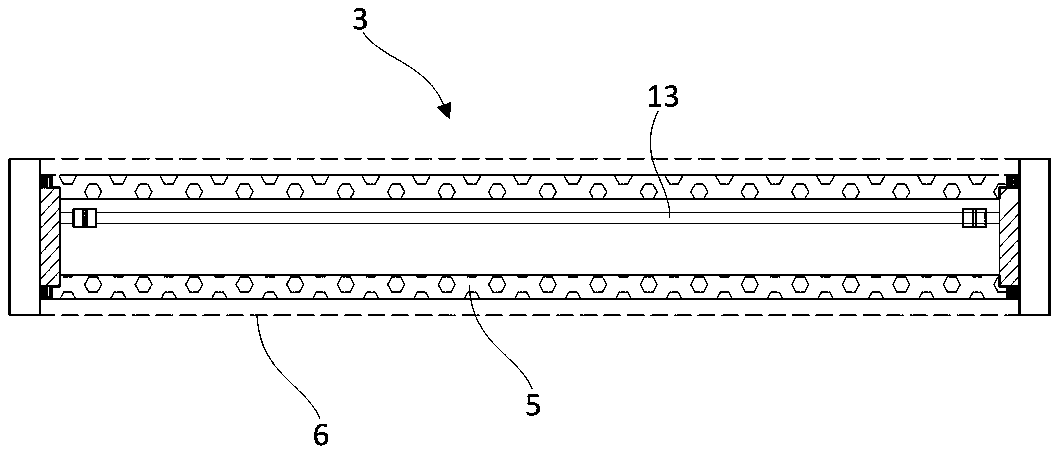

[0030] like figure 2 As shown, the water injection test chamber 3 includes a water permeable flower tube 5 and a water injection cavity filter screen 6 sleeved on the outside of the water permeable flower tube 5; It can flow to the outside of the water injection test chamber 3 .

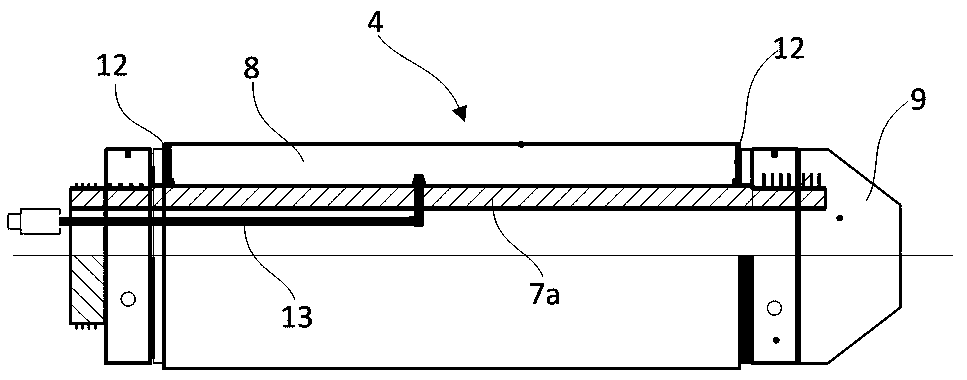

[0031] like figure 2 , 3 , 4, the upper water-stop cavity 2 and the lower water-stop cavity 4 both include a steel pipe 7 and an expansion airbag 8 sleeved on the outside of the steel pipe 7; The top of the steel pipe 7a is coaxially sealed and connected; in order to facilitate the connection, a hexagonal wrench bayonet is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com