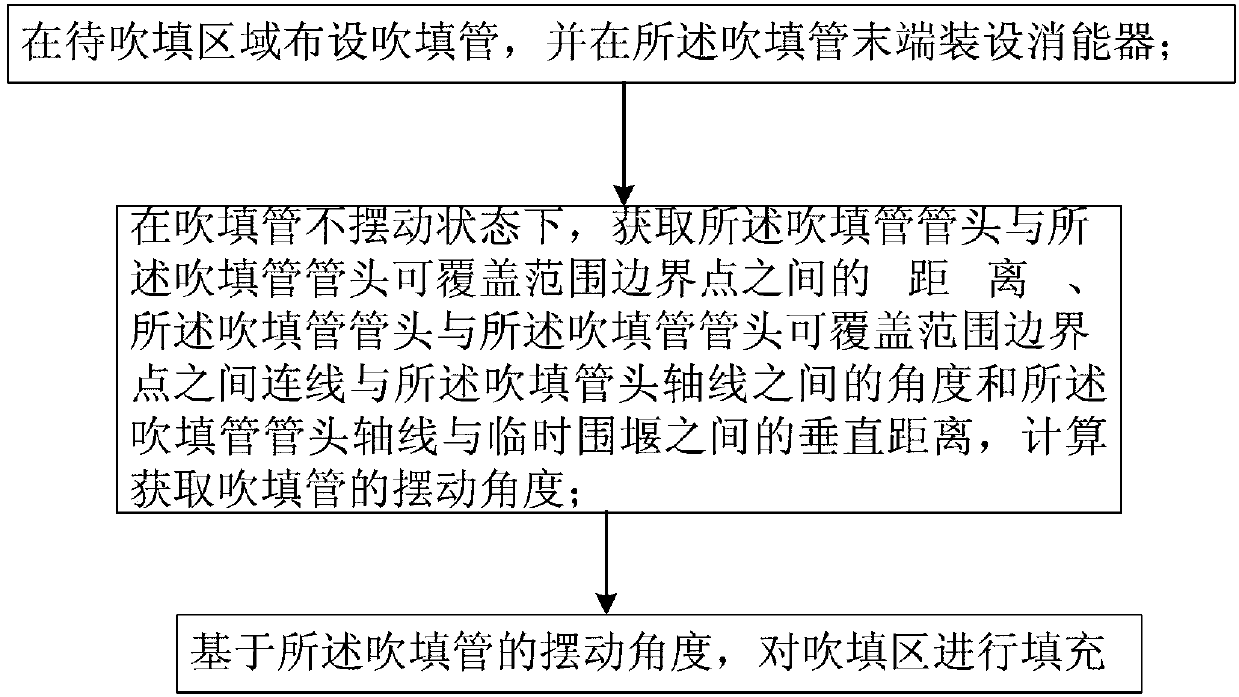

Method for improving hydraulic fill flatness

A technology of flatness and blow-fill pipes, which is applied in the fields of soil protection, instruments, and data processing applications, etc. It can solve the problems of low levelness and low precision of blow-fill, so as to improve the flatness of blow-fill and reduce the nozzle Impulse, the effect of increasing the diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

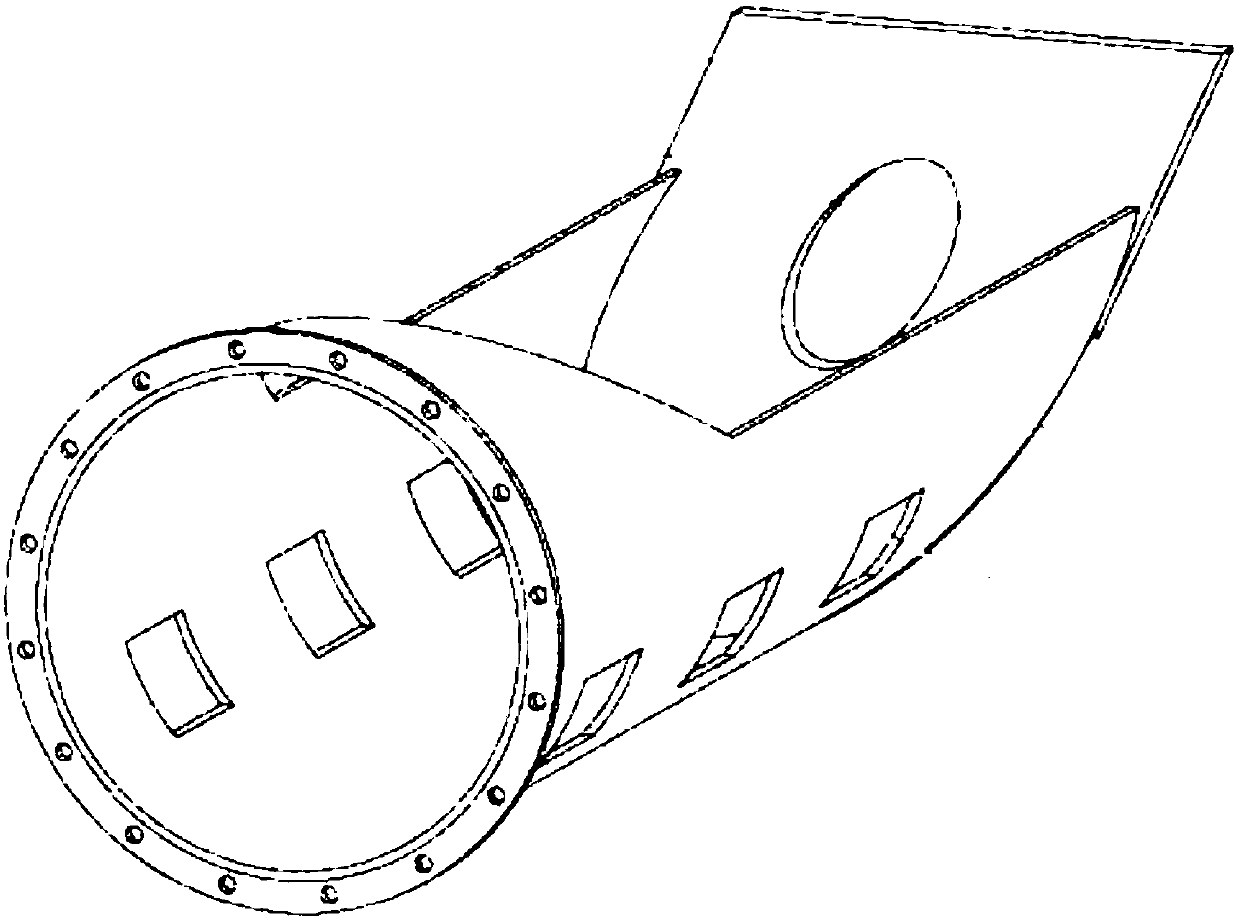

[0022] It should be noted that a method of improving the levelness of dredging and filling according to the present invention is based on floating temporary cofferdams, wherein the floating temporary cofferdams include floating breakwaters, inner weirs and reverse flow weirs, floating The vertical breakwater and the anti-reflux weir are arranged vertically to form an L-shaped fence. The inner barrier weir is installed outside the anti-reflux weir in parallel with the floating breakwater, and the anti-reflux weir is equipped with a blow-fill pipe, which passes through the anti-reflux weir. Extending to one side of the floating breakwater, and the floating breakwater is spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com