Woven fabric with one-way guiding and absorbing function and production technology thereof

A production process, one-way technology, used in textiles, fabrics, textiles and papermaking, etc., can solve the problems of poor dimensional stability of the cloth, residual sweat, low snagging resistance and low wear resistance of the cloth, and achieve dimensional stability. Good, maintain continuous effect, the effect of large diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

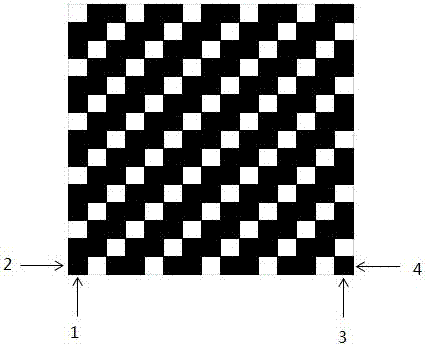

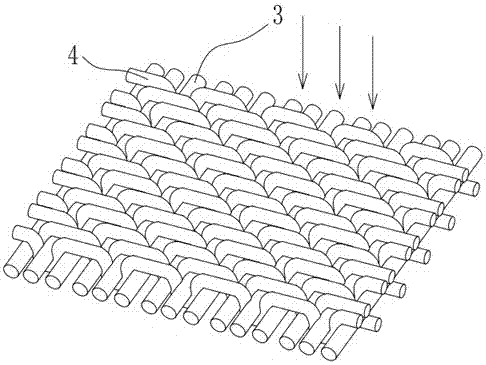

[0048] Such as Figure 1~3 As shown, this embodiment discloses a twill woven fabric with a unidirectional suction function. Its production process is as follows:

[0049]Step 1 selects the yarn: (1) the warp yarn selects 150D / 96F polyester false twist textured yarn 3, and the warp yarn needs 1100 grains; (2) the weft yarn selects 150D / 144F polypropylene false twist textured yarn 4, and this yarn is the original Draw black yarn.

[0050] Step 2 warping: at a speed of 350m / min, the warp yarns are evenly arranged together by a warping machine to form a whole shaft, and a total of 7 whole shafts need to be made.

[0051] Step 3 Sizing: At a speed of 60m / min, the yarn is sizing through a sizing machine, and finally wound on a new shaft to form a sizing shaft; the water jet loom adopts acrylic size for sizing, and the yarn is sizing The concentration is controlled at 7%, the sizing temperature is controlled at 45°C, and the slurry is HW-226 acrylic slurry from Jiangyin Haohe.

...

Embodiment 2

[0060] Such as Figure 4~6 As shown, this embodiment discloses a woven fabric with a dobby weave, which has a unidirectional suction function, and the fabric has better elasticity, and the fabric has good comfort. Its production process is as follows:

[0061] Step 1 select the yarn: (1) use 50D / 72F polyester false twist textured yarn 3 for the warp yarn, and the number of warp yarns needs to be 1100; (2) use two kinds of yarns for the weft yarn: yarn 1 uses 50D / 32F polyester physical elastic yarn Yarn 5 can make the cloth surface have a good elastic effect in the weft direction; yarn 2 uses 75D / 72F polypropylene false twist textured yarn 4, this yarn is used for the skin surface, and its touch is delicate and comfortable, of which polypropylene yarn is the original Draw black yarn; the ratio of polyester physical elastic yarn 5 and polypropylene false twist textured yarn 4 in the weft yarn is 2:1.

[0062] Step 2 Warping: At a speed of 380m / min, the warp yarns are evenly ar...

Embodiment 3

[0072] Such as Figure 7 As shown, this embodiment discloses a woven fabric with dobby weave, which has a unidirectional suction function, and the fabric has better elasticity and good comfort. Its production process is as follows:

[0073] Step 1 Select the yarn: (1) use 30D / 72F polyester false twist textured yarn 3 for the warp yarn, and the number of grains required for the warp yarn is 1320; (2) select two kinds of yarns for the weft yarn: yarn 1 selects 30D / 24F polyester mechanical elastic Yarn 6 can make the cloth surface have a certain elastic effect in the weft direction; yarn 2 uses 75D / 72F polypropylene air textured yarn 7, this yarn is used for the skin surface, and its touch is delicate and comfortable, and the polypropylene yarn is the original black color Yarn; the ratio of polyester mechanical elastic yarn 6 to polypropylene air textured yarn 7 in the weft is 2:1.

[0074] Steps 2-10 are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com