Control mechanical arm, molecular hybridization instrument and operation method of control mechanical arm

A technology of manipulators and control mechanisms, applied in the field of manipulators, can solve problems such as insufficient automation, simple functions, and space occupation of molecular hybridization instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] Embodiments of the present invention will be described in detail below.

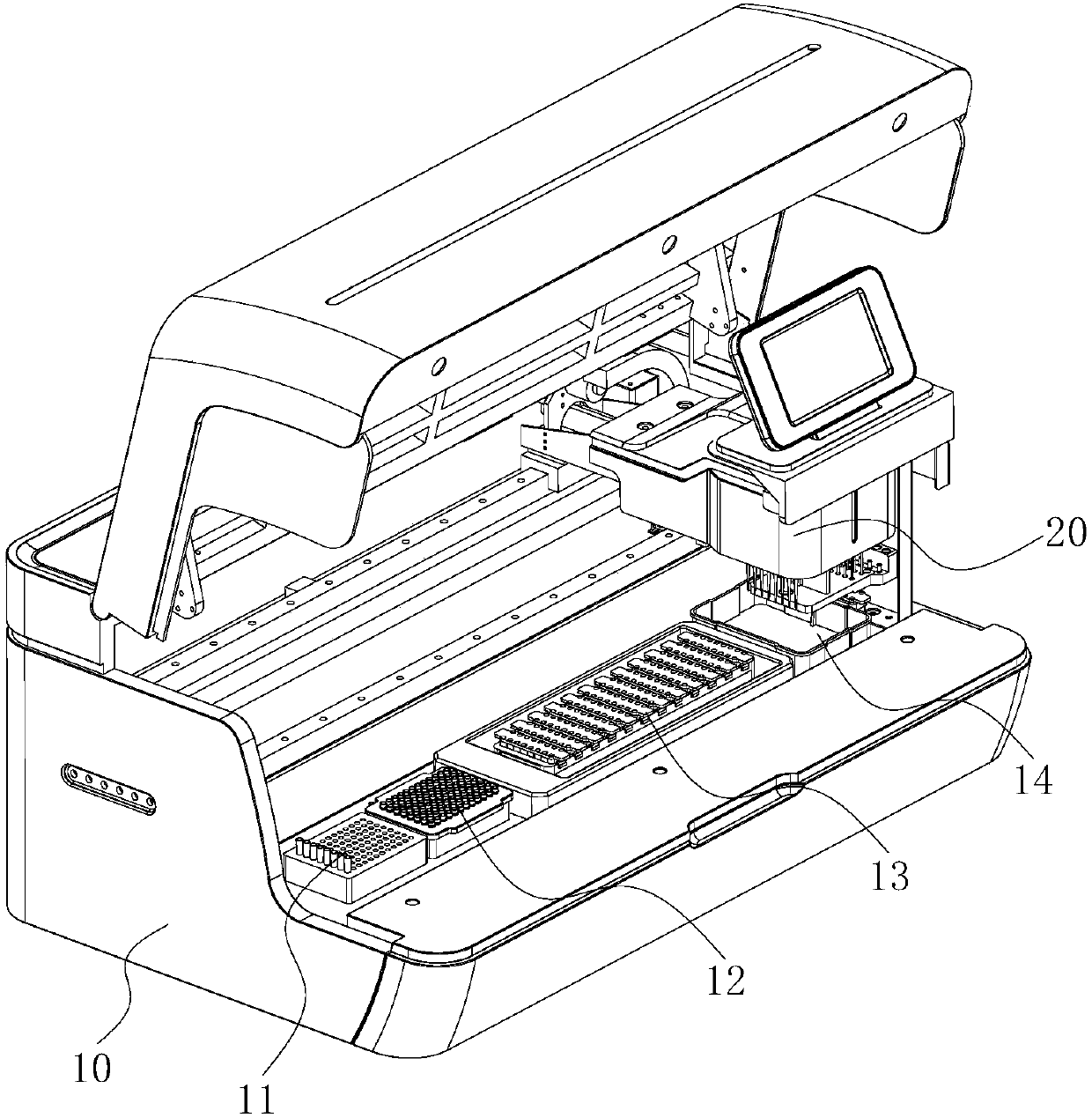

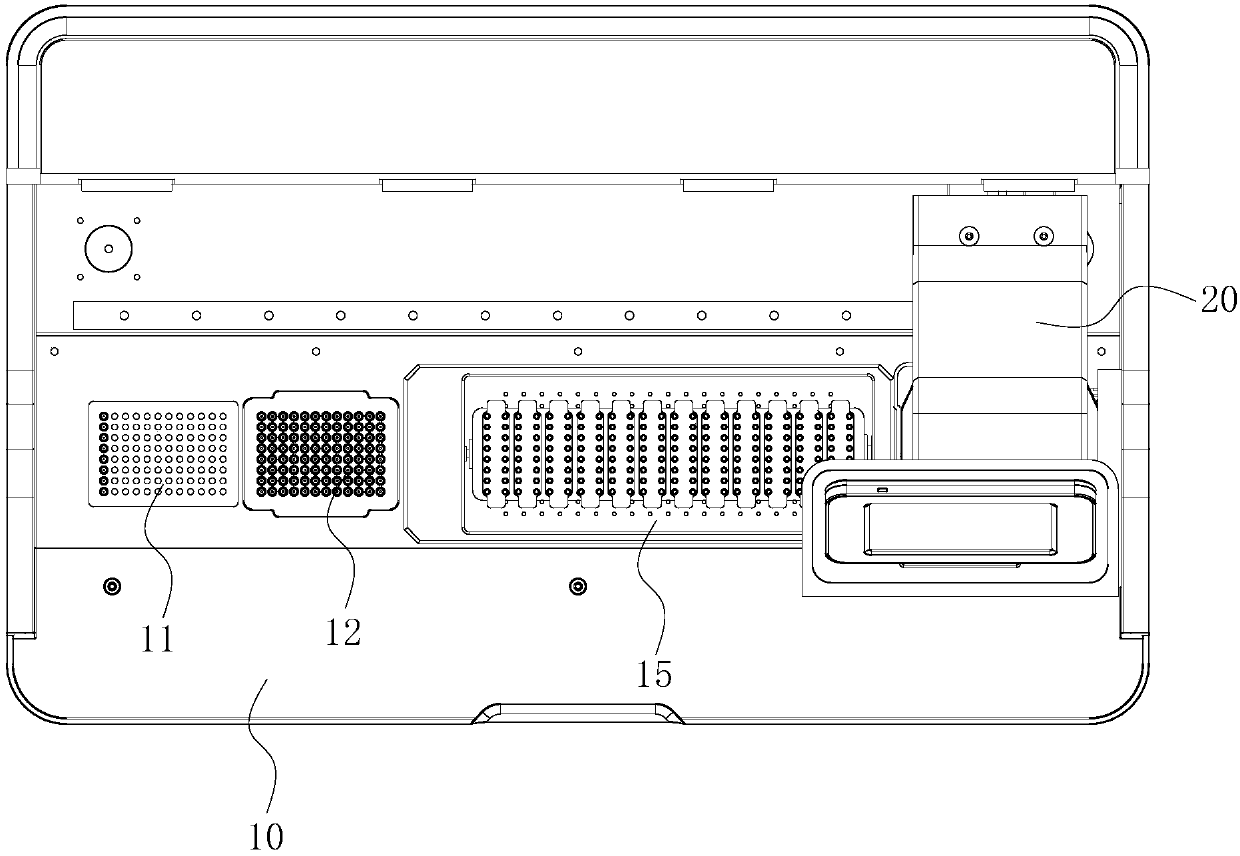

[0120] Such as Figure 1 to Figure 17 As shown, the molecular hybridization instrument includes a frame body 10, and the frame body 10 is provided with a tip placement part 11, a sample placement part 12, a reaction part 13, a waste collection part 14, a control manipulator 20 and a manipulator moving drive mechanism,

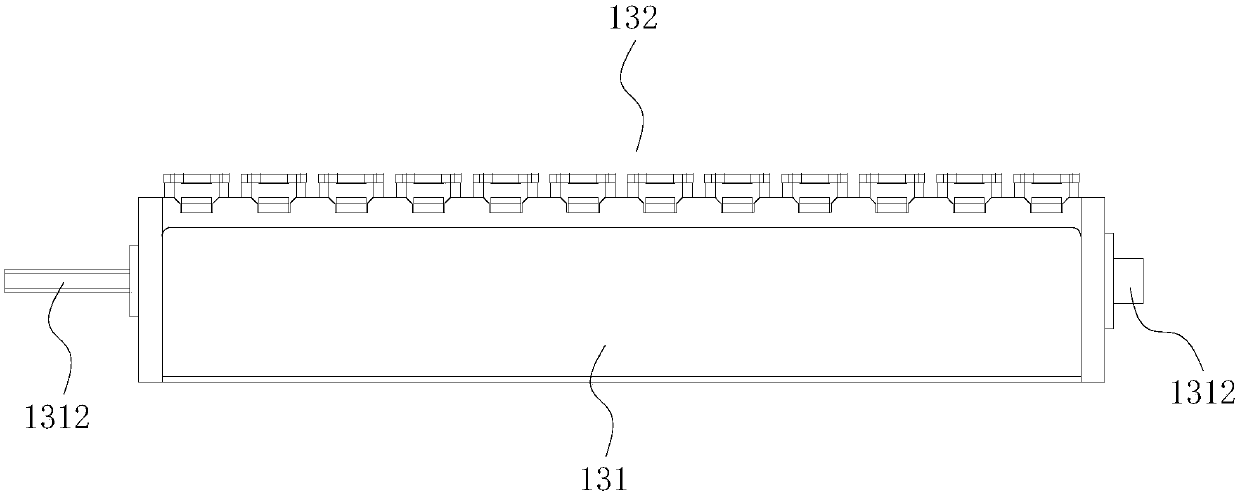

[0121] The tip placement part 11 has a plurality of tip placement chambers; the sample placement part 12 has a plurality of sample placement chambers; the reaction part 13 has a rotating chamber 131 and a reaction chamber 132, and the rotating chamber 131 is rotatably arranged in the frame body 10, and the rotating chamber 131 has a placement chamber 1311, and the reaction chamber 132 is arranged in the placement chamber 1311, and the reaction chamber 132 has a reaction chamber; the waste collection part 14 has a waste collection chamber;

[0122] The manipulator 20 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com