Counterpoint device of cutting machine

A technology of alignment device and cutting machine, which is applied in the field of TFT-LCD manufacturing process, can solve the problems of increased production cost, expensive porous carbon fiber material, unfavorable popularization, etc., and achieve the effect of ensuring smooth use, reducing cost, and ensuring alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

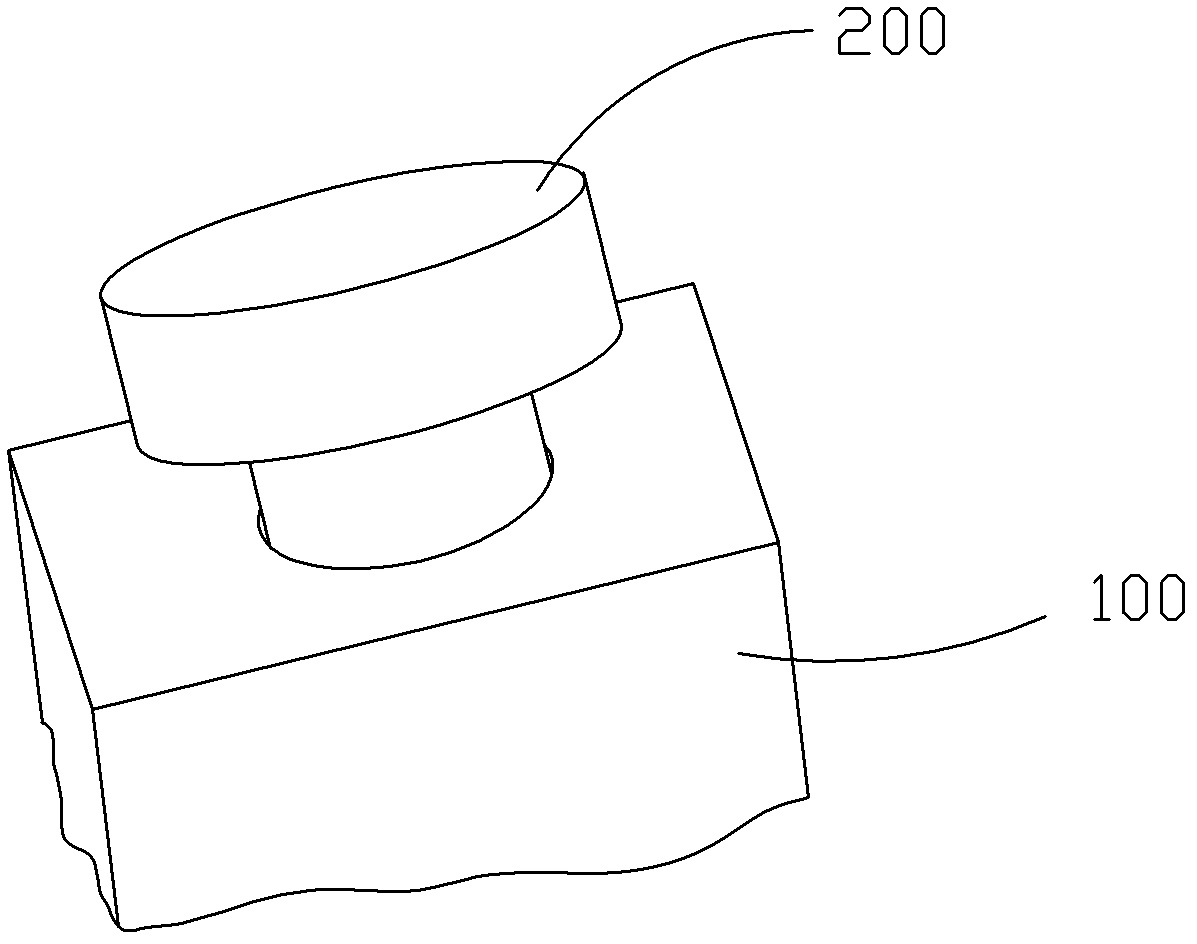

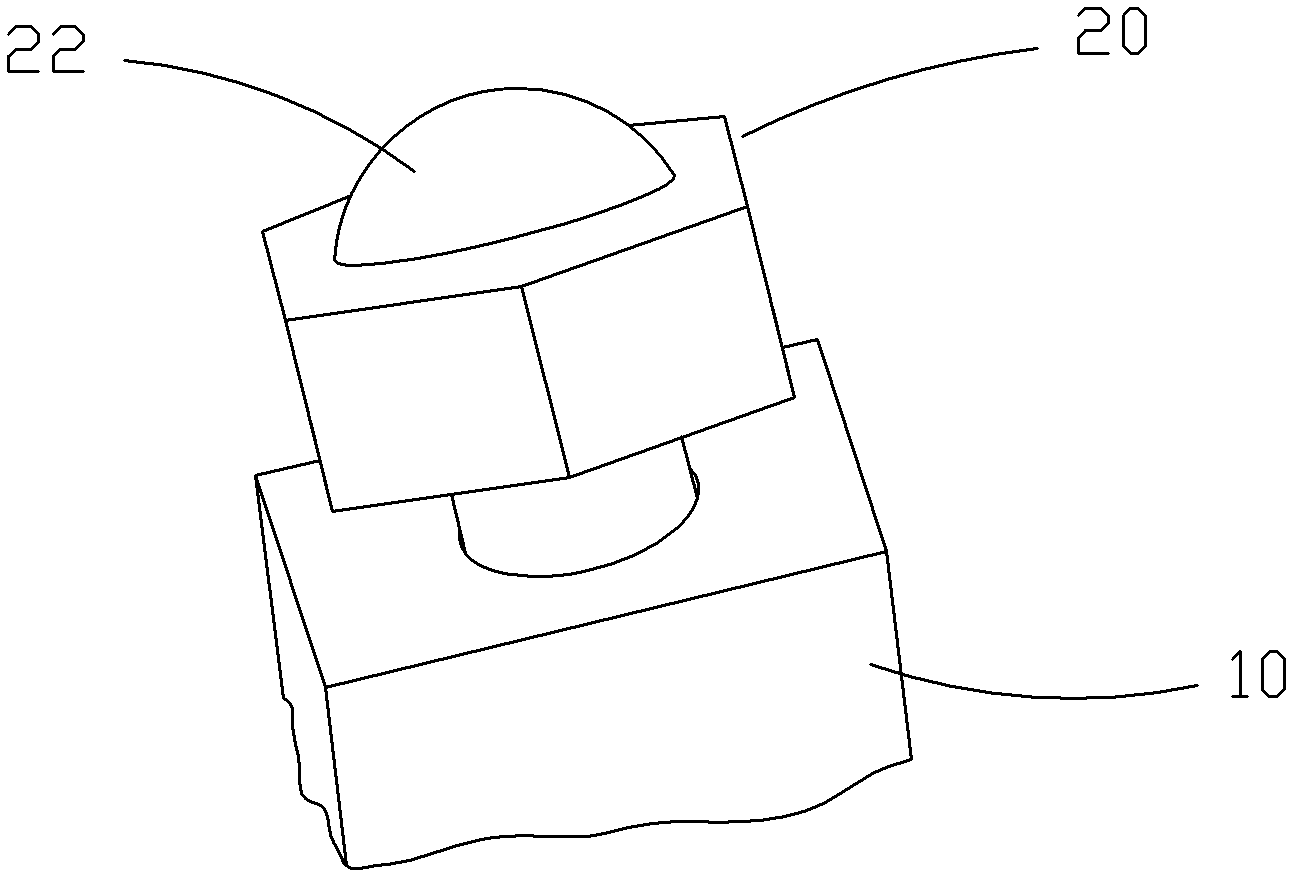

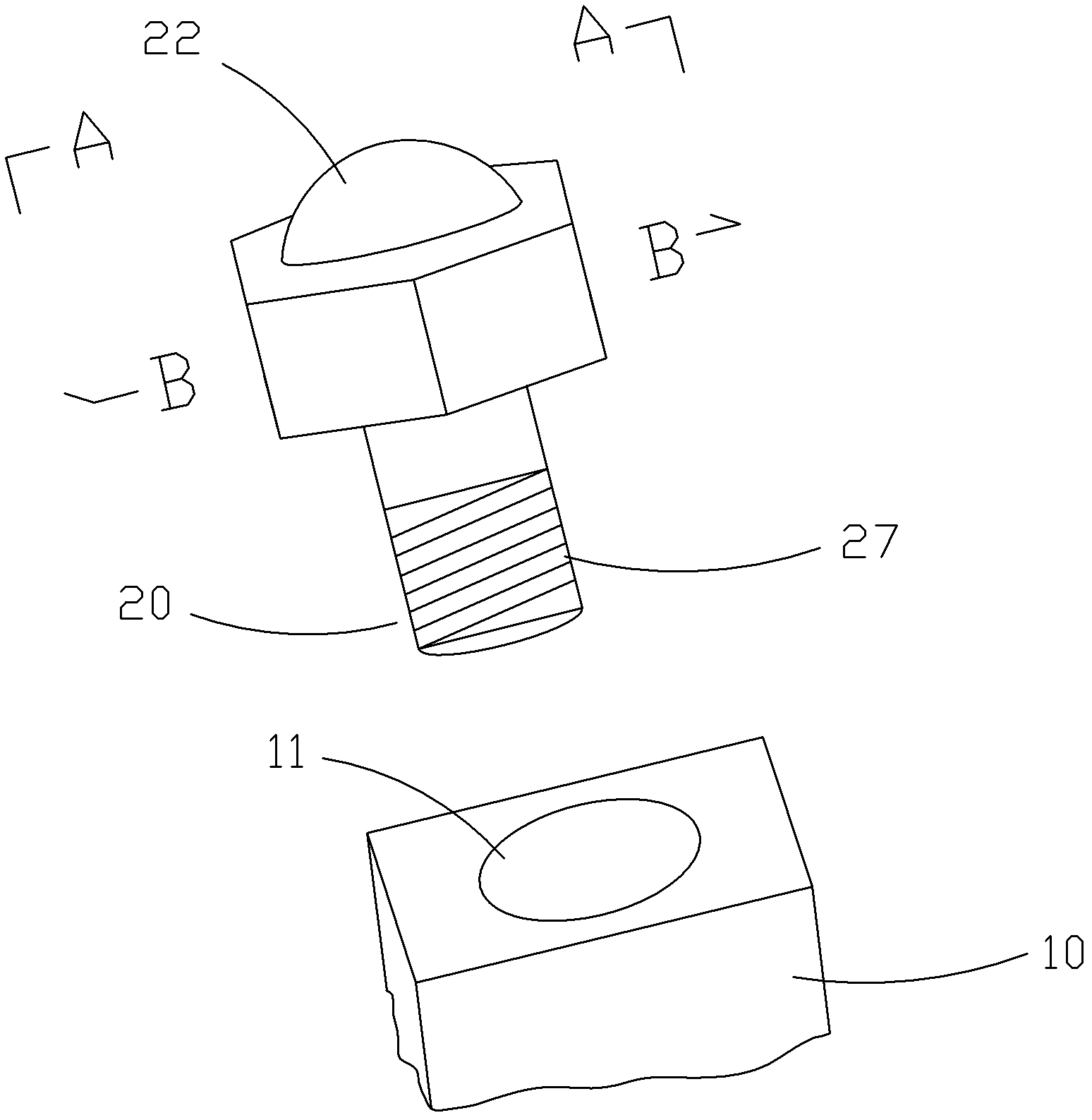

[0022] Such as Figure 2-6 As shown, the present invention provides an alignment device for a cutting machine, which includes: a mounting base 10, and a universal ball 20 installed on the mounting base. works the same way. In the present invention, the universal ball 20 is used to replace the floating pad made of porous carbon fiber material to align the glass substrate, so as to reduce the cost.

[0023] The universal ball 20 includes a main body 21, a first rolling body 22, and several second rolling bodies 23 arranged between the main body 21 and the first rolling body 22. One end of the main body 21 is provided with an accommodating groove 24 to form a The side wall 241 of the accommodation groove, the second rolling body 23 is rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com