Novel microbubble oxygenated biological membrane silk and water treatment method

A biofilm and microbubble technology, applied in the field of water treatment, can solve the problems of unstable membrane structure, low oxygen utilization, large power consumption, etc., and achieve the effects of improving growth, metabolism and reproduction, improving treatment efficiency and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A new type of microbubble oxygenated biofilm silk and water treatment method of the present invention will be further described below in conjunction with the examples, but the patent is not limited to the following examples. In conjunction with accompanying drawings, carry out detailed description.

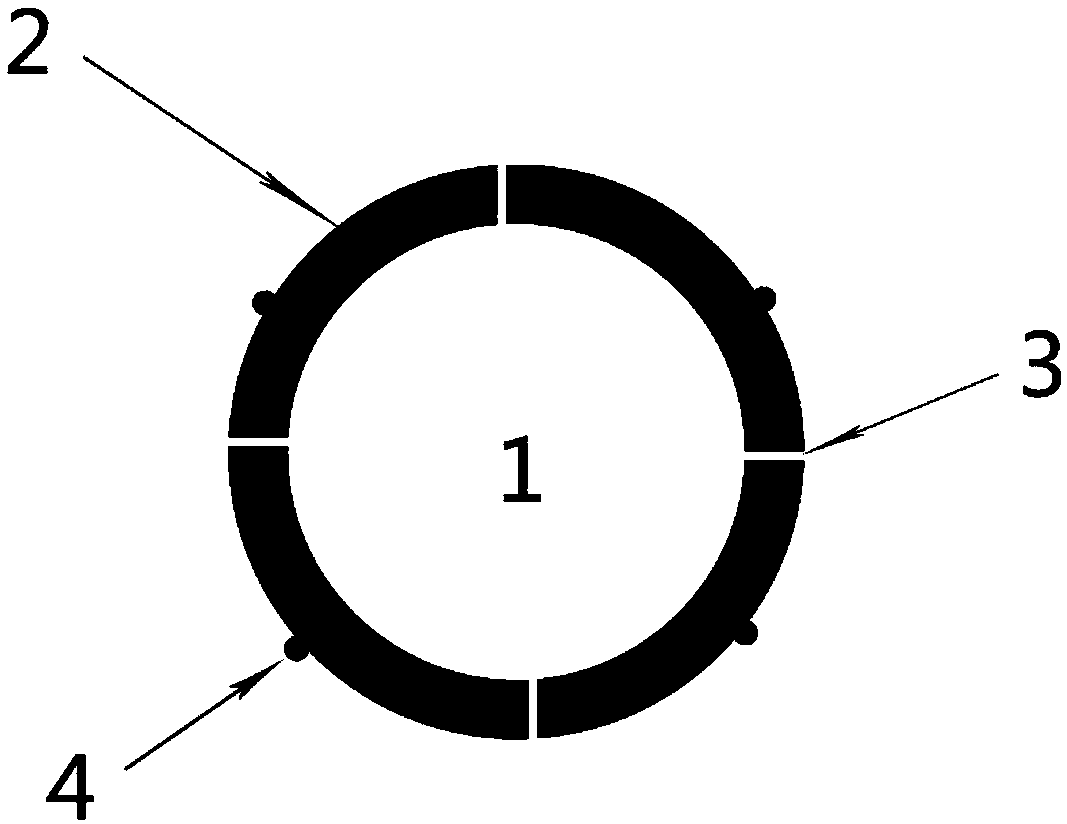

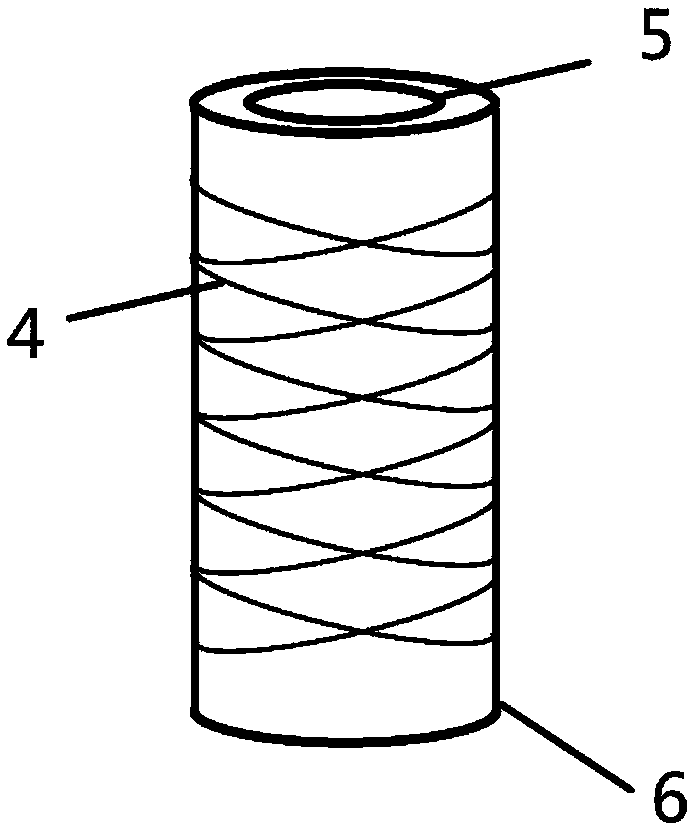

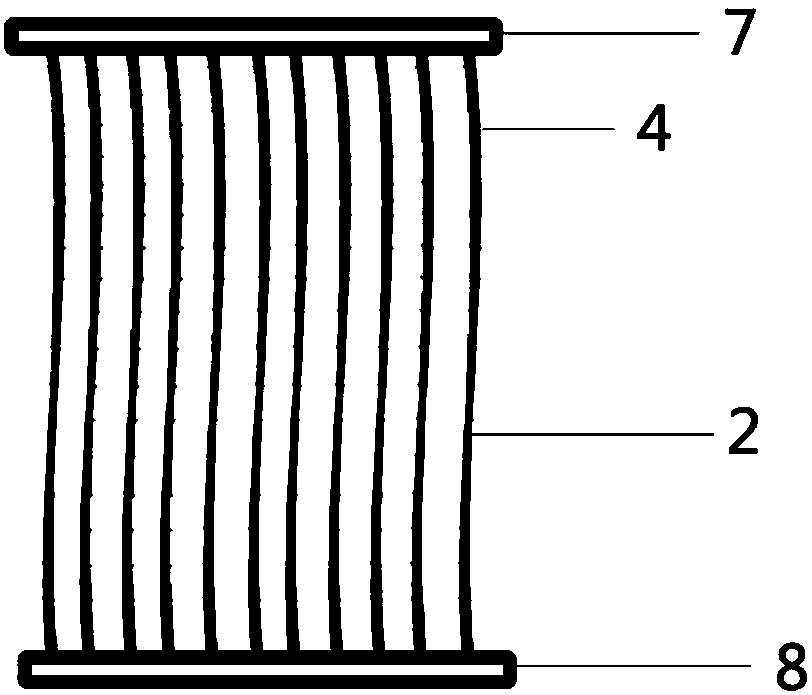

[0027] A new type of microbubble oxygenated biofilm silk, which is composed of hydrophobic material 5, hydrophilic coating 6 and hydrophilic structure reinforced braid 4; the inner layer of microbubble oxygenated biofilm silk 2 is hydrophobic material 5. The middle layer is a hydrophilic coating 6, and the outer layer is a hydrophilic structural reinforcement braid 4, and the three layers are adhered to each other; the hydrophilic coating is applied on the outer surface of the hydrophobic material membrane without blocking the membrane The wall hole 3, the liquid phase water body will not infiltrate the inside of the membrane filament 5, that is, keep the inside of the memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com