Inner rotor aircraft structure

A rotorcraft and rotor technology, applied in the field of aircraft, can solve the problems of insufficient compact structure, enlarged blade size, inability to realize vertical take-off and landing and air suspension, etc., and achieve the effect of compact structure and strong maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

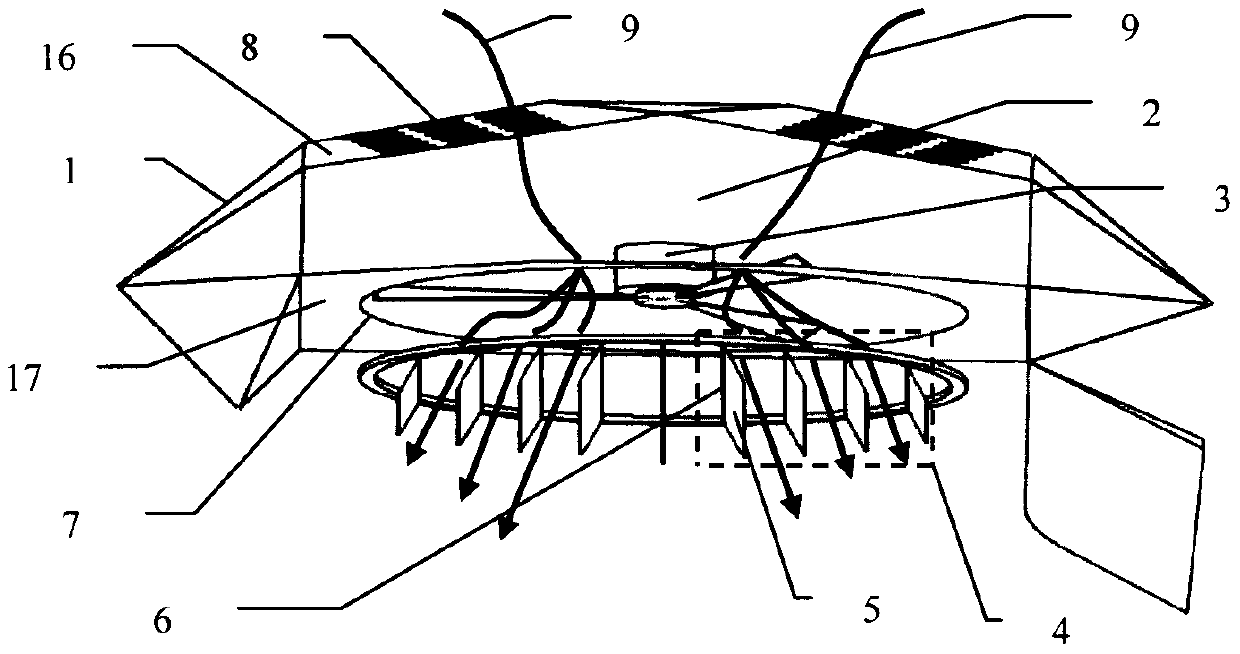

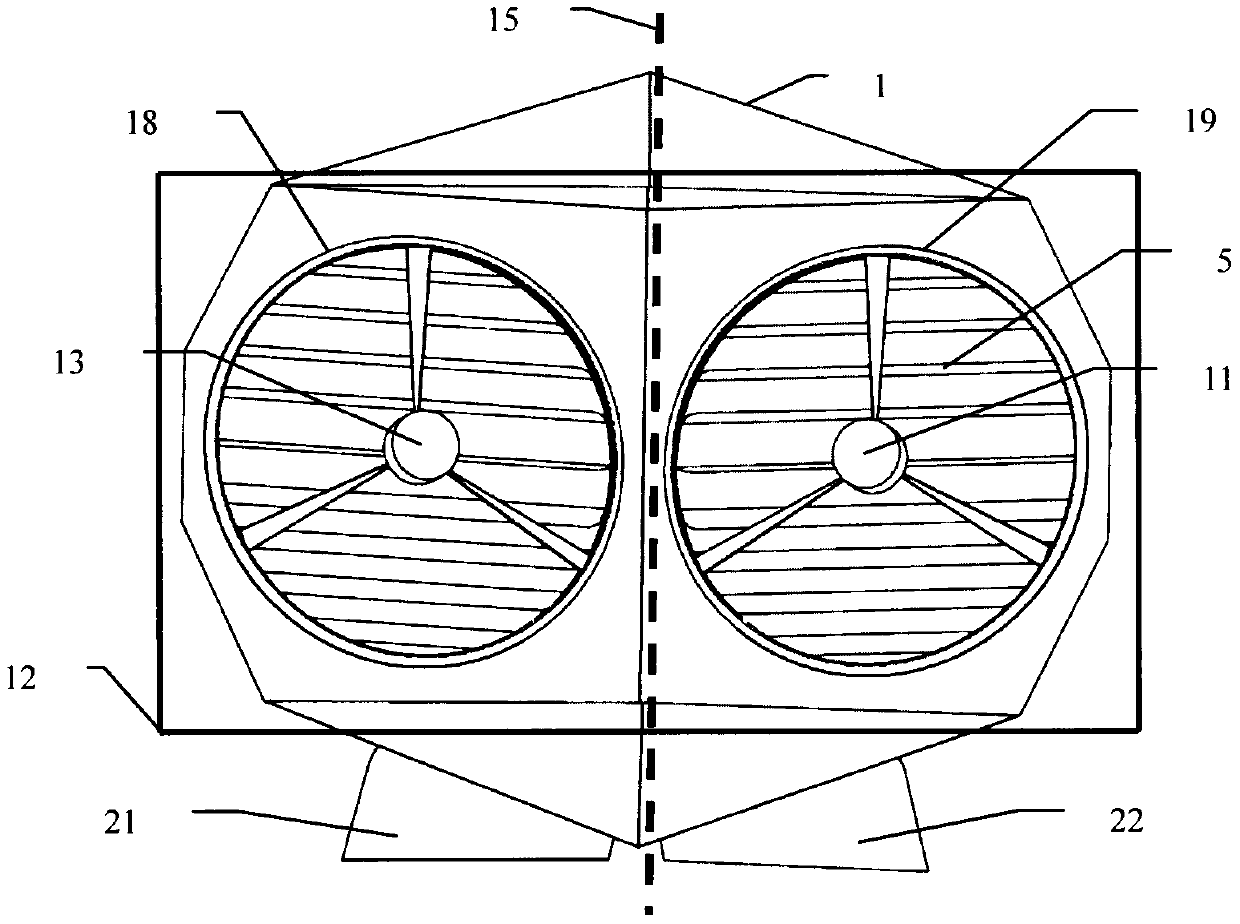

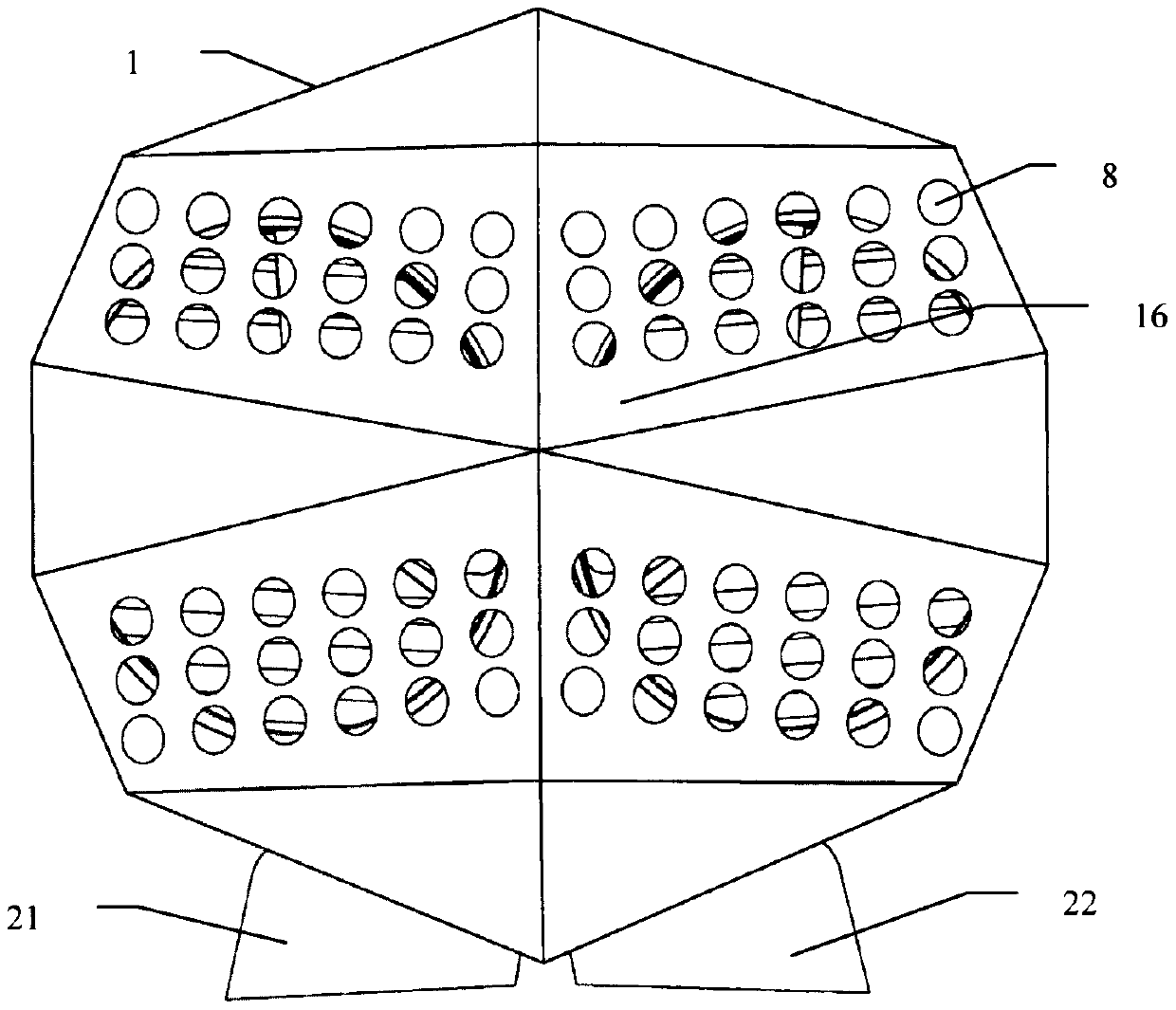

[0039] This embodiment provides a kind of aircraft structure with left and right inner rotors, as follows:

[0040] Such as Figure 1-6 As shown, it includes a body (1), a rotor chamber (2), an air inlet (8), an air outlet (7), a deflector (5), and a rotor (3), wherein the rotor chamber (2) is embedded in the Inside the body (1), the body (1) is provided with the air inlet (8) and the air outlet (7), the air inlet (8), the air outlet (7) and the rotor cavity (2) communicate with each other, the deflector (5) is installed at the air outlet (7), and the rotor (3) is installed in the rotor chamber (2).

[0041] Optionally, the deflector (5) is in the shape of a long thin sheet, and the deflector (5) is provided with a deflector rotation shaft (6), and the deflector (5) can rotate around the The deflector rotating shaft (6) rotates.

[0042] Optionally, a plurality of guide vanes (5) form a guide vane group (4), and the planes of the guide vanes (5) in the same guide vane group...

Embodiment 2

[0062] This embodiment provides an aircraft structure with up and down inner rotors, which is another modified form of the aircraft structure with left and right inner rotors provided in Embodiment 1, and is used to illustrate an inner rotor aircraft provided by the present invention Structural variability.

[0063] Such as Figure 7 As shown, the left and right inner rotors in the rotor chamber described in Embodiment 1 are changed to upper and lower inner rotors, that is, an upper rotor (24) and a lower rotor (25) are provided in the rotor chamber (2), and the The upper rotor (24) and the lower rotor (25) are installed in cascaded form in the rotor cavity (2), the rotation axis of the upper rotor (24), the rotation axis of the lower rotor (25) and the body center The vertical and vertical lines (23) are coaxial, and the rotation plane of the upper rotor (24) and the rotation plane of the lower rotor (25) are parallel to each other. The upper rotor (24) and the lower rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com