a potato slicer

A slicer and potato technology, applied in metal processing, etc., can solve the problems of being unsuitable for ordinary families, high cost and price, and large size, and achieve the effect of simple and reliable design, low manufacturing cost, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

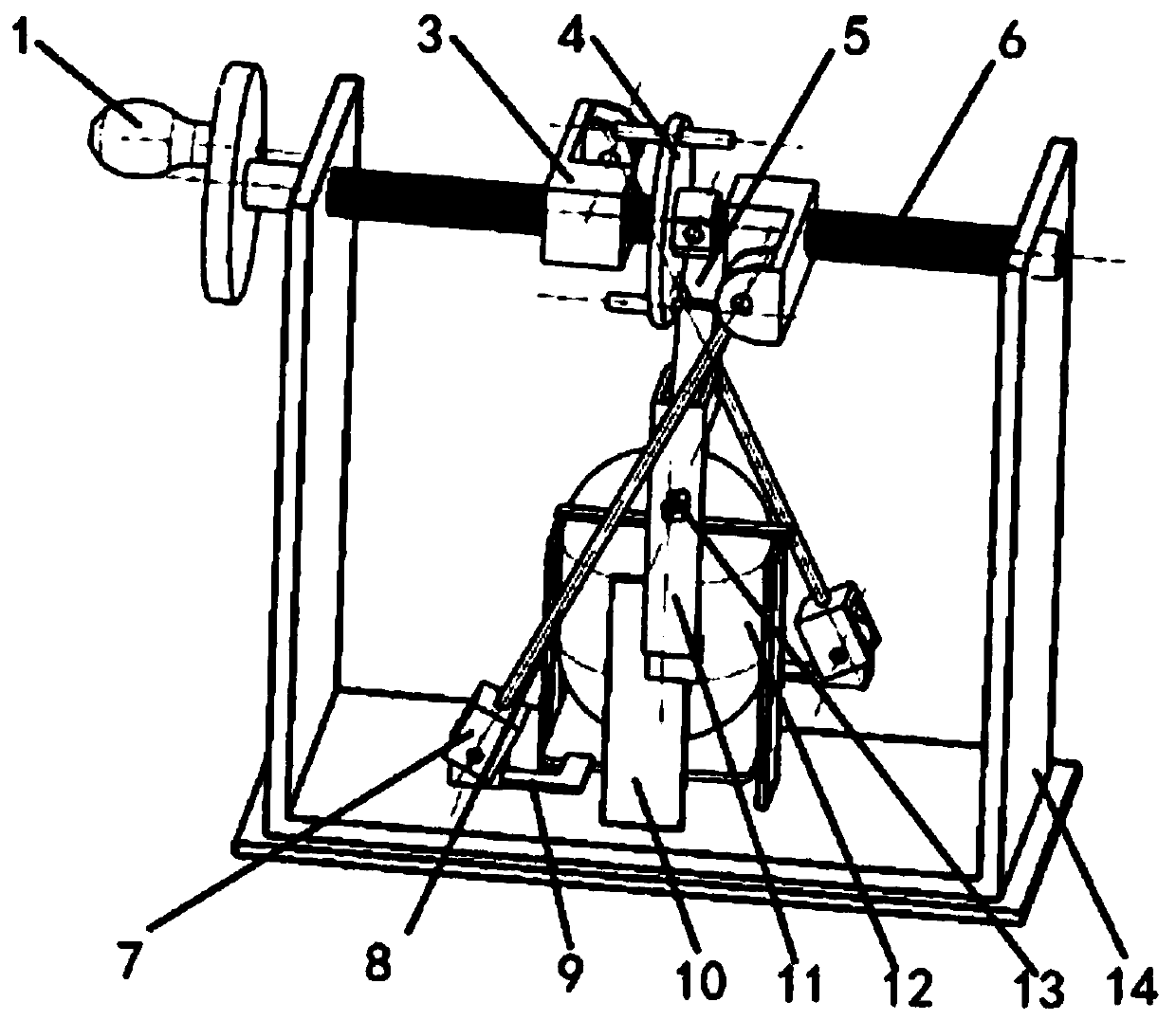

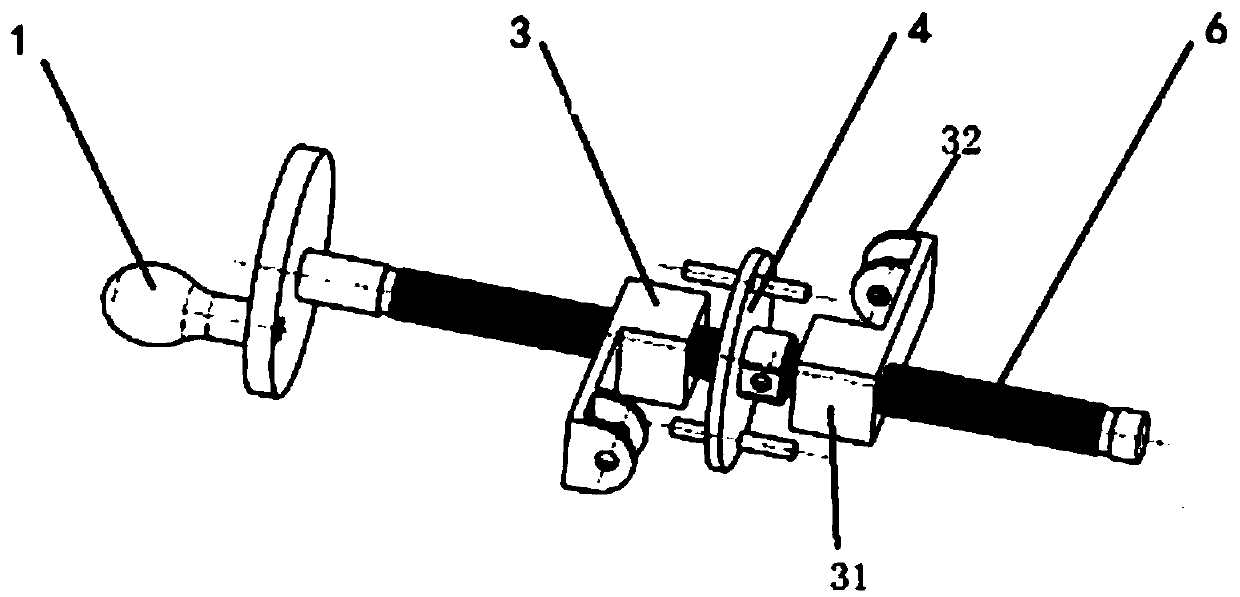

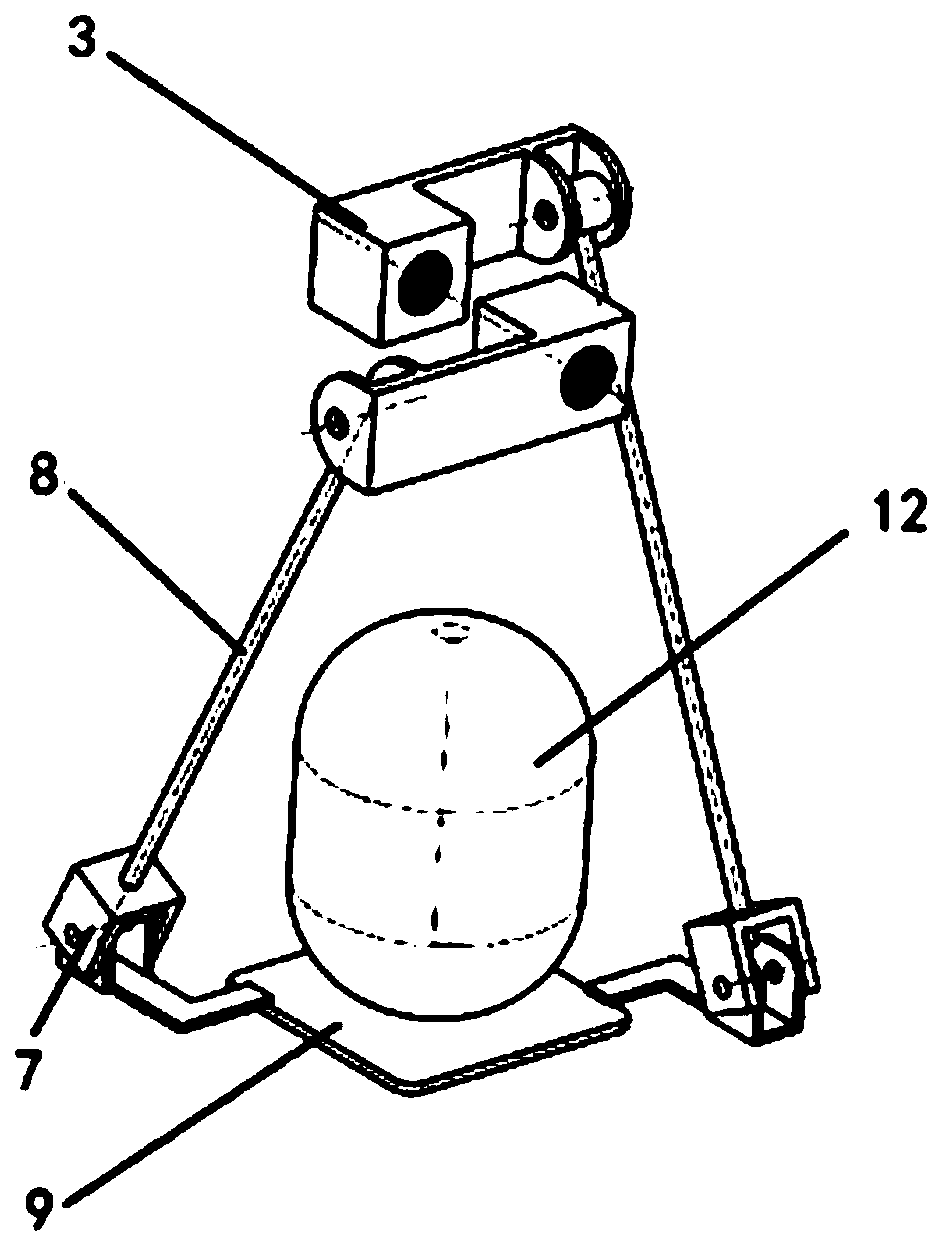

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 5 As shown, the present invention discloses a potato slicer, which includes a moving block 3, a driving turntable 4, a knife 5, a threaded guide rod 6, a cylindrical head connecting rod 8, a bottom support platform 9, a limit plate 10, a spring 13 and a base 14 , the threaded guide rod 6 is rotatably connected to the base 14 , and the driving turntable 4 is fixed on the threaded guide rod 6 . A forward threaded part and a reversed threaded part are provided on the threaded guide rod 6, and the forward and reversed threaded parts are placed symmetrically on both sides of the drive turntable 4 respectively, and the two moving blocks 3 are screwed to the forward threaded part respectively. and on the reverse threaded part. The bottom ends of the two cylinder-head connecting rods 8 are hinged on both sides of the supporting platform 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com