Self-sealing pressurizing plate type filter

A disc filter, self-sealing technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of increasing equipment and civil construction investment, high equipment and civil construction investment, and high discharge height , to achieve the effect of facilitating maintenance, saving energy consumption, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

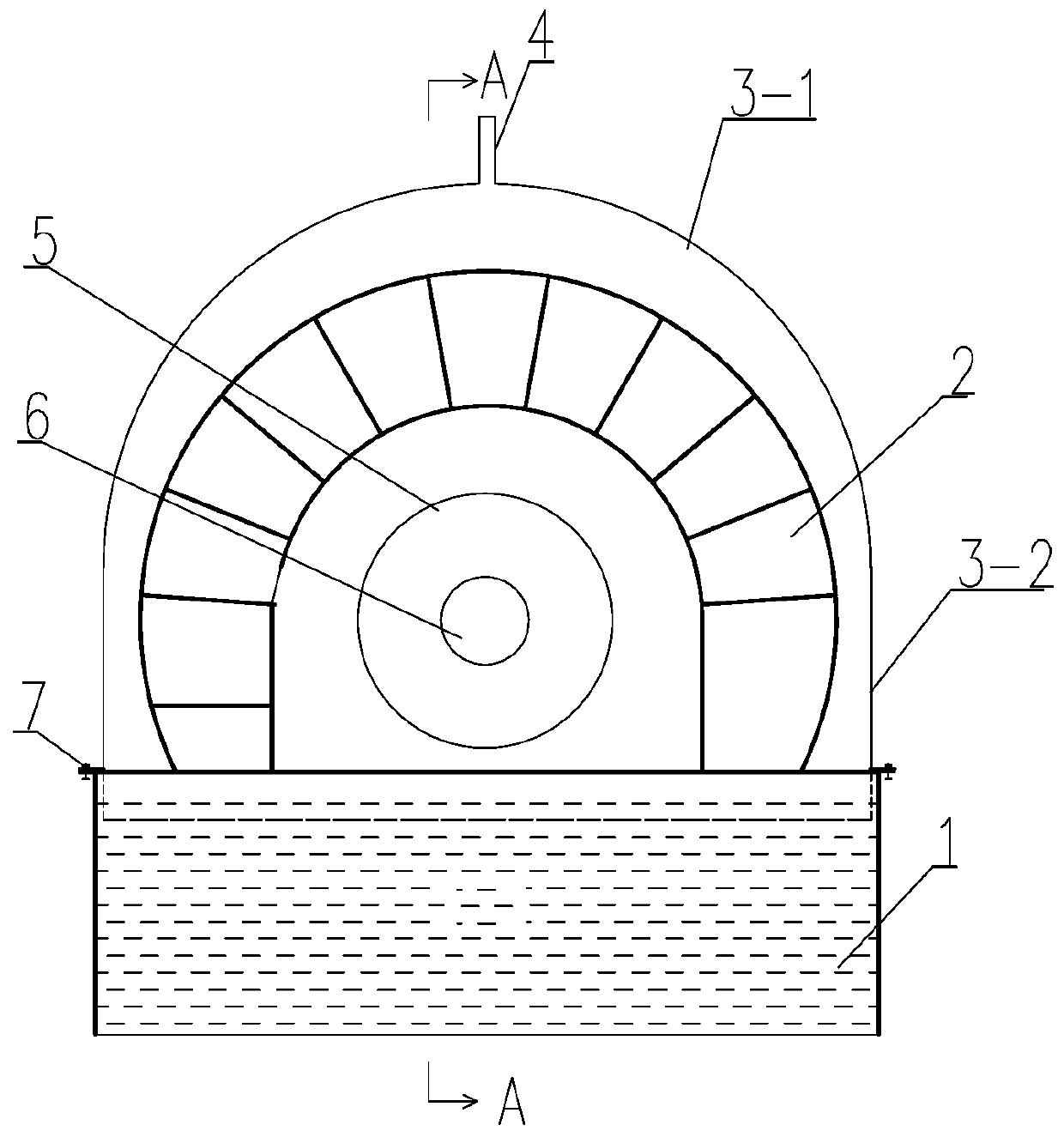

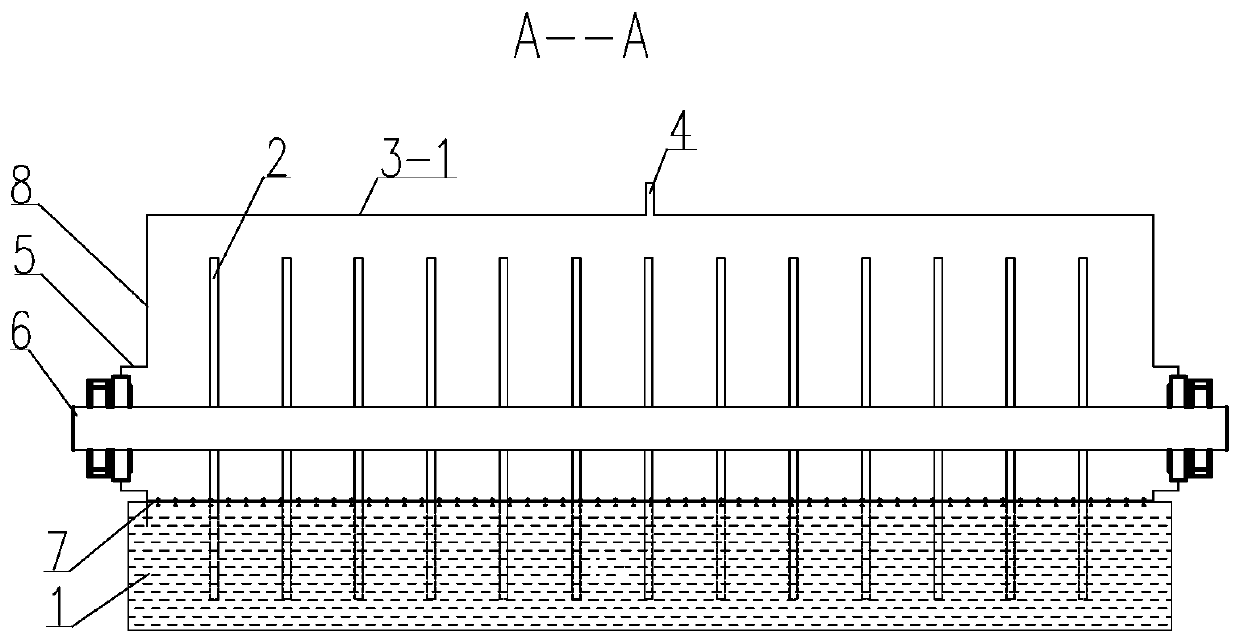

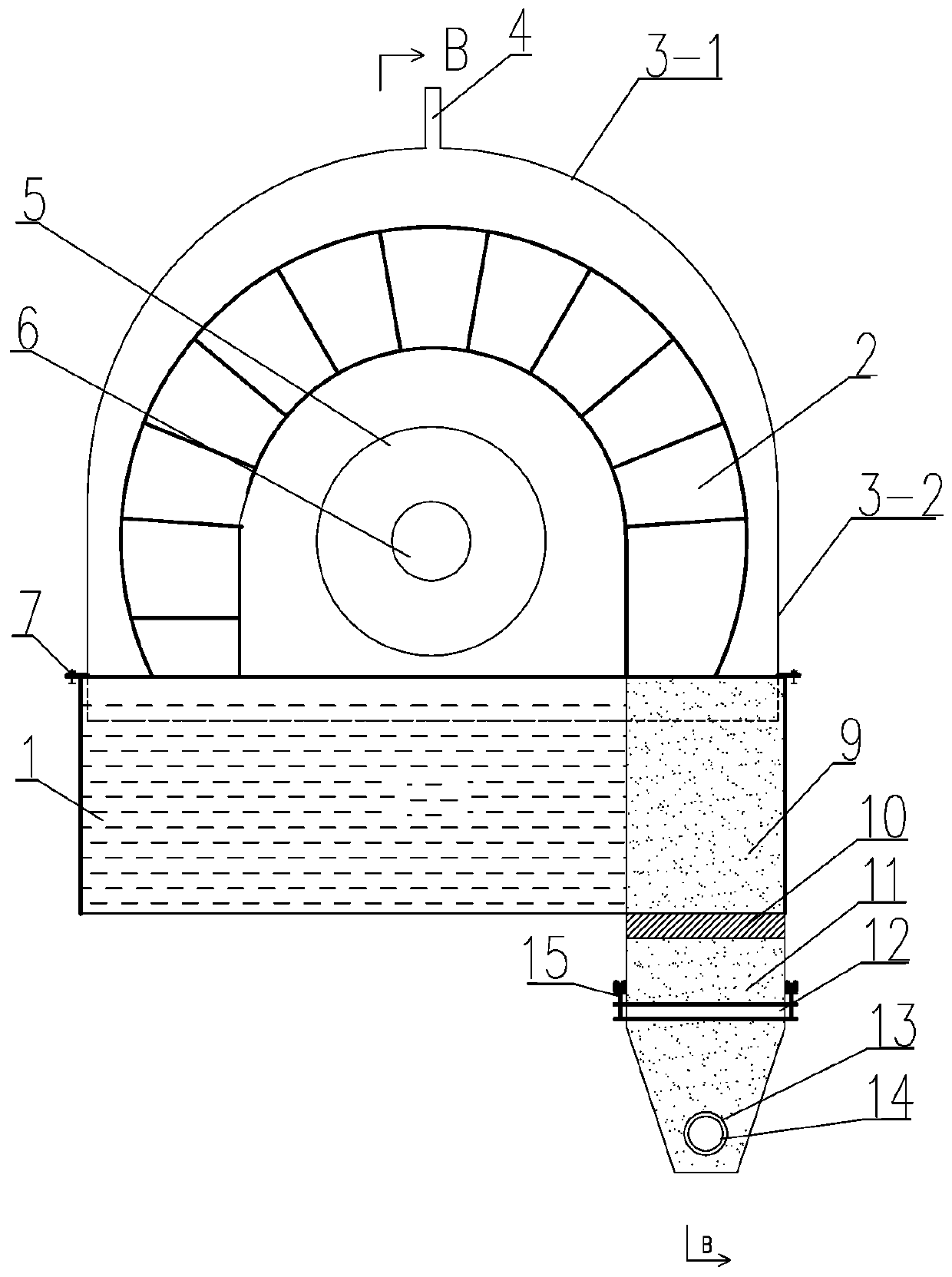

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1-Figure 4 As shown, a self-enclosed pressurized disc filter of the present invention includes a main shaft 6, at least one circular filter disc 2 fixed on the main shaft 6 arranged axially along the main shaft, a slurry tank 1, and a discharge tank 9 , a scraper device for unloading, a pressurization system and a discharge system, characterized in that:

[0026] The pressurization system includes a pressurization chamber arranged on the upper part of the slurry tank 1 and the discharge tank 9, and the pressurization chamber is composed of an upper arc-shaped chamber body, two end faces and a central cylinder 5,

[0027] The two end faces are respectively composed of semicircular end faces at both ends of the arc-shaped chamber body and a rectangular end face 8 with a shaft hole welded to the lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com