Dendrobium polysaccharide emulsion containing coconut oil and preparation method thereof

A Dendrobium polysaccharide and coconut oil technology, applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of dendrobium polysaccharide system damage, poor stability, and system viscosity reduction, and achieve viscosity and uniform stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

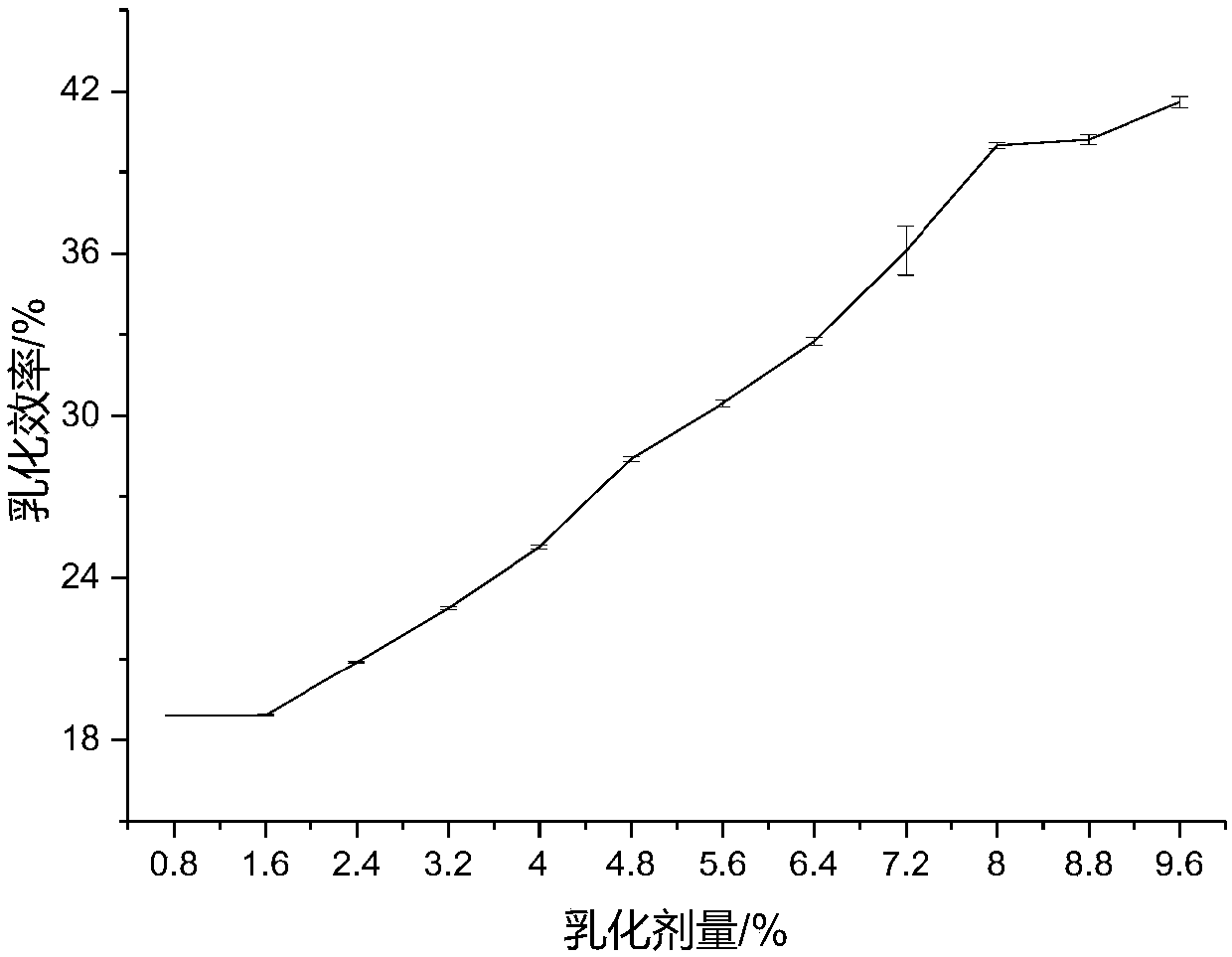

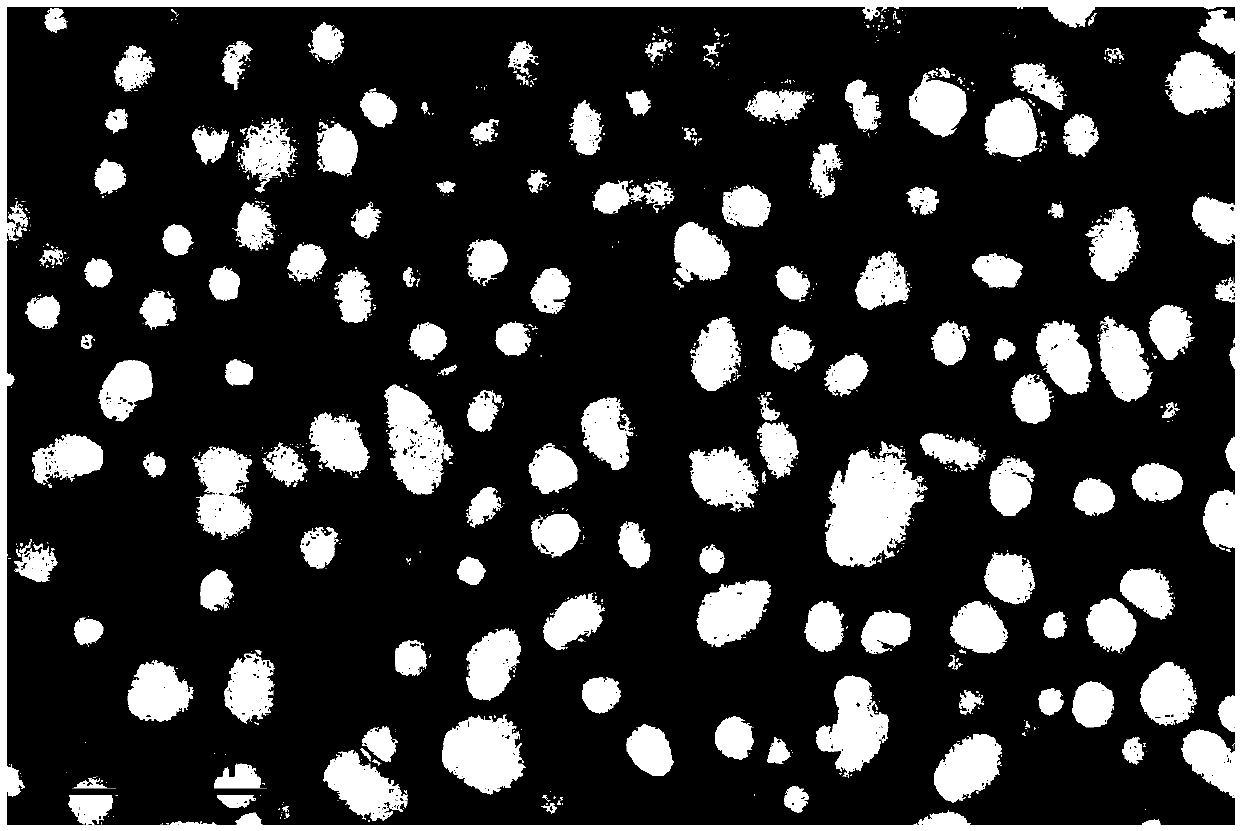

[0031] Embodiment 1: prepare the dendrobium polysaccharide emulsion containing coconut oil of the present invention

[0032] Distilled glyceryl monostearate (HLB value=3.8) 3g, sucrose fatty acid ester (HLB value=15) 7g, surfactant HLB value after compounding is 11.6, deionized water 260g, mix under the condition of 60 degrees Celsius, Allow distilled glyceryl monostearate, sucrose fatty acid ester to fully dissolve to form an aqueous phase. Add 30 grams of cold-pressed coconut oil to the water phase (oil phase: water phase=1:9, the surfactant accounts for 3.33% of the total weight of the oil phase and the water phase), stir and mix at 70 degrees Celsius, and constantly add Glycerol, until the coconut oil oil droplets are all dispersed to form a self-emulsifying microemulsion system with blue opalescence, set aside.

[0033] The freshly harvested Dendrobium candidum stems are used as raw materials, cut into sections, added with deionized water, and beaten with a tissue masher...

Embodiment 2

[0035] Embodiment 2: preparation of the dendrobium polysaccharide emulsion containing coconut oil of the present invention

[0036]Will distill glyceryl monostearate 1.5g (HLB value=3.8), glyceryl monolaurate 1.5g (HLB value=5.2), sucrose fatty acid ester 7g (HLB value=15), surfactant HLB after compounding The value is 11.85, and 260g of deionized water is mixed at 70 degrees Celsius to allow distilled glyceryl monostearate, glyceryl monolaurate and sucrose fatty acid ester to fully dissolve to form an aqueous phase. Add 60 grams of cold-pressed coconut oil to the water phase (oil phase: water phase=2:9, the surfactant accounts for 3.03% of the total weight of the oil phase and the water phase), stir and mix at 70 degrees Celsius, and constantly add Glycerol, until the coconut oil oil droplets are all dispersed to form a self-emulsifying microemulsion system with blue opalescence, set aside.

[0037] The freshly harvested Dendrobium candidum stems are used as raw materials, c...

Embodiment 3

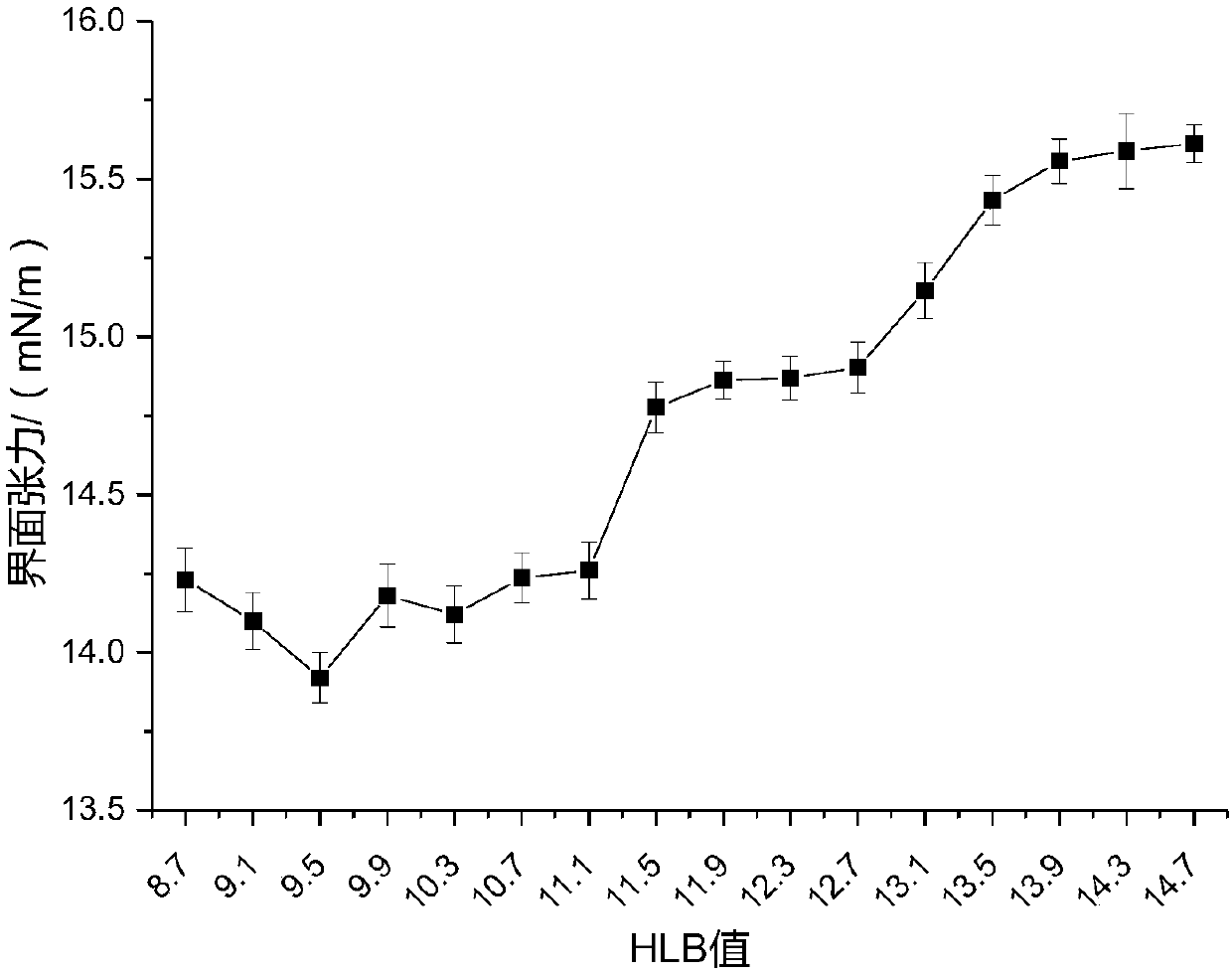

[0039] Embodiment 3: the determination of composite surfactant HLB value

[0040] 1. Compounding of three surfactants

[0041] Composite surfactants A (distilled glyceryl monostearate), B (glycerol monolaurate) and C (sucrose fatty acid ester) are used to obtain composite surfactants with different HLB values. According to different HLB values, press formula to determine their respective mass fractions.

[0042]

[0043] Where: W ABC =W A +W B +W C

[0044] HLB ABC - the HLB value of the composite surfactant;

[0045] HLB A - the HLB value of A;

[0046] HLB B - the HLB value of B;

[0047] HLB C - the HLB value of C;

[0048] W A - the mass fraction of A in the solution, %;

[0049] W B - the mass fraction of B in the solution, %;

[0050] W C - the mass fraction of C in the solution, %;

[0051] W ABC - the mass fraction of complex surfactant in the solution, %.

[0052] 2. Compounding of two surfactants

[0053] Composite surfactants A (distilled gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com