A Simulation Method for Surface Topography Modeling and Forming of Side Milling Ruled Surface

A technology of ruled surface and surface topography, applied in the field of precision machining, can solve the problems of low efficiency and low simulation accuracy, and achieve the effects of improving simulation accuracy, improving simulation efficiency and saving simulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

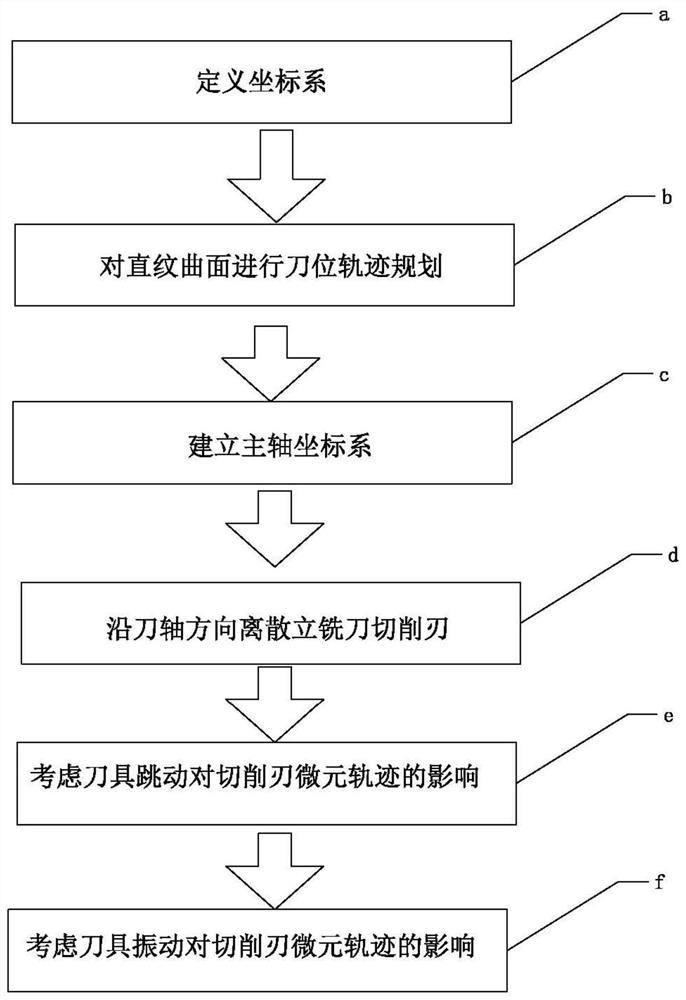

[0044] like figure 1 As shown, the surface topography modeling method of a side milling ruled surface provided by the present invention comprises the following steps:

[0045] a. Define the coordinate system;

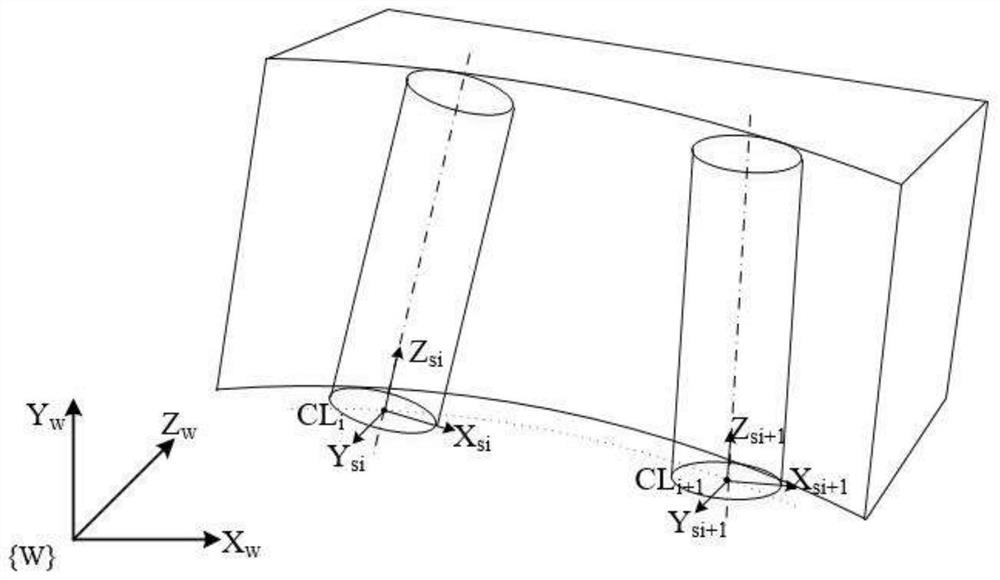

[0046] In order to describe the pose of the tool relative to the workpiece during the machining process, the following main coordinate systems are defined, including the workpiece coordinate system {W}, the spindle coordinate system {S}, the tool coordinate system, the cutter tooth coordinate system and the auxiliary coordinate system, such as image 3 shown; as Figure 5 As shown, set the coordinate system {1}, coordinate system {2}, and coordinate system {3}.

[0047] b. Carry out tool position trajectory planning on the ruled surface;

[0048] For tool position trajectory planning on ruled surfaces, CAM software (such as UG) can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com