Method for performing electrolytic extraction on ultrafine carbide in steel

An electrolytic extraction and carbide technology, applied in the preparation of test samples, etc., can solve the problems of small size of ultrafine carbide, difficult non-destructive separation, carbide erosion, etc., and achieve the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

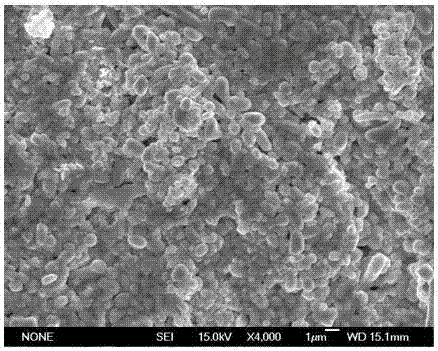

Image

Examples

Embodiment 1

[0023] Embodiment 1: The method for electrolytic extraction of ultrafine carbides in steel adopts the following specific processes.

[0024] (1) The formula of the electrolyte is as follows (wt%): tetramethylammonium chloride 4%, acetylacetone 10%, ethylene glycol 5%, triethanolammonium 3%, and ethanol with a purity of 99.9% as the balance. Into a mixed solution; In addition, add 5g of diphenylguanidine and 10 grams of urethane pin in every liter of mixed solution by volume.

[0025] (2) Put the above electrolytic solution into the electrolytic cell; put the GCr15 steel sample containing carbides into the electrolytic cell after polishing and cleaning, as the anode; 316L stainless steel plate as the cathode; pass in argon gas with a flow rate of 0.3 liters / minutes; the temperature of the electrolyte is 0-3°C; adjust the electrolysis potential to 3.5V, and the current density is 0.045A / cm 2 , The electrolysis time is 28 hours.

[0026] (3) Put the above-mentioned electrolyte...

Embodiment 2

[0027] Embodiment 2: The method for electrolytically extracting ultrafine carbides in steel adopts the following specific processes.

[0028] (1) The formula of the electrolyte is as follows (wt%): tetramethylammonium chloride 3%, acetylacetone 12%, ethylene glycol 6%, triethanolammonium 2%, and ethanol with a purity of 99.9% as the balance. Into a mixed solution; In addition, add 5g of diphenylguanidine and 10 grams of urethane pin in every liter of mixed solution by volume.

[0029] (2) Put the 82A steel sample containing carbides into the electrolytic cell after polishing and cleaning, as the anode, and place it in the anode position in the middle of the electrolytic cell; the 316L stainless steel plate is used as the cathode; argon gas is introduced, and its flow rate is controlled to 0.8 liters / min; the temperature of the electrolyte is controlled by an ice bath to 0-3°C; the electrolytic potential is adjusted to 3.0V, and the DC current density is 0.035A / cm 2 , electro...

Embodiment 3

[0031] Embodiment 3: The method for electrolytic extraction of ultrafine carbides in steel adopts the following specific processes.

[0032] (1) The formula of the electrolyte is as follows (wt%): tetramethylammonium chloride 5%, acetylacetone 8%, ethylene glycol 3%, triethanolammonium 4%, and ethanol with a purity of 99.9% as the balance. Into a mixed solution; In addition, add 5g of diphenylguanidine and 10 grams of urethane pin in every liter of mixed solution by volume.

[0033] (2) Put the 50CrV30A steel sample containing carbides into the electrolytic cell after polishing and cleaning, as the anode, and place it at the anode position in the middle of the electrolytic cell; nitrogen gas is introduced, and its flow rate is controlled at 0.5 liters / min; The ice bath is controlled at 0-3°C; the 316L stainless steel plate is used as the cathode; the electrolysis potential is adjusted to 4.5V, and the DC current density is 0.06A / cm 2 , electrolysis for 25 hours.

[0034] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com