Cantilever fulcrum jumping detecting tool and method

A jump detection and fulcrum technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems that the turbine rotor cannot get the runout value and blade tip clearance, so as to avoid the inability to check and solve the inability to accurately detect and measure get accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

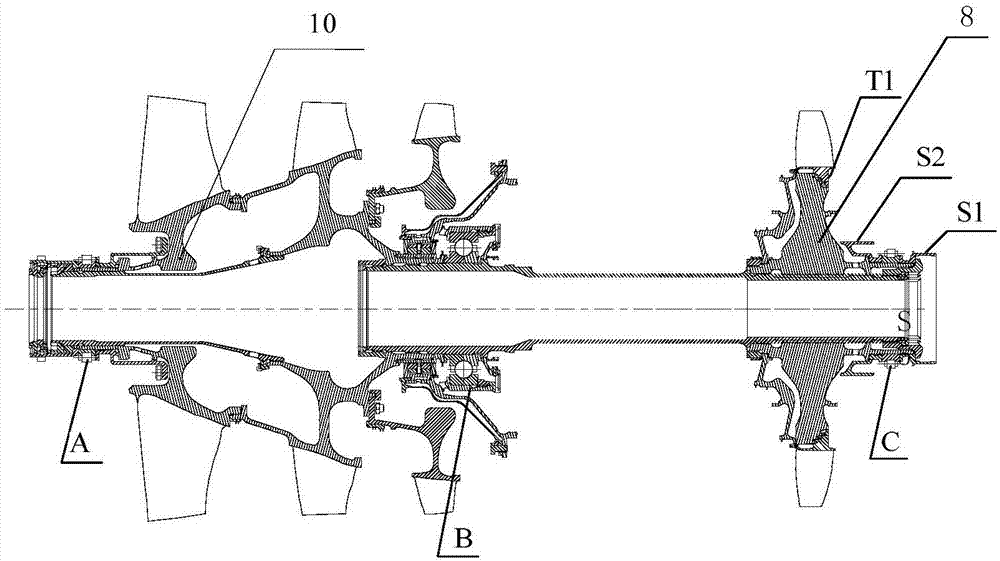

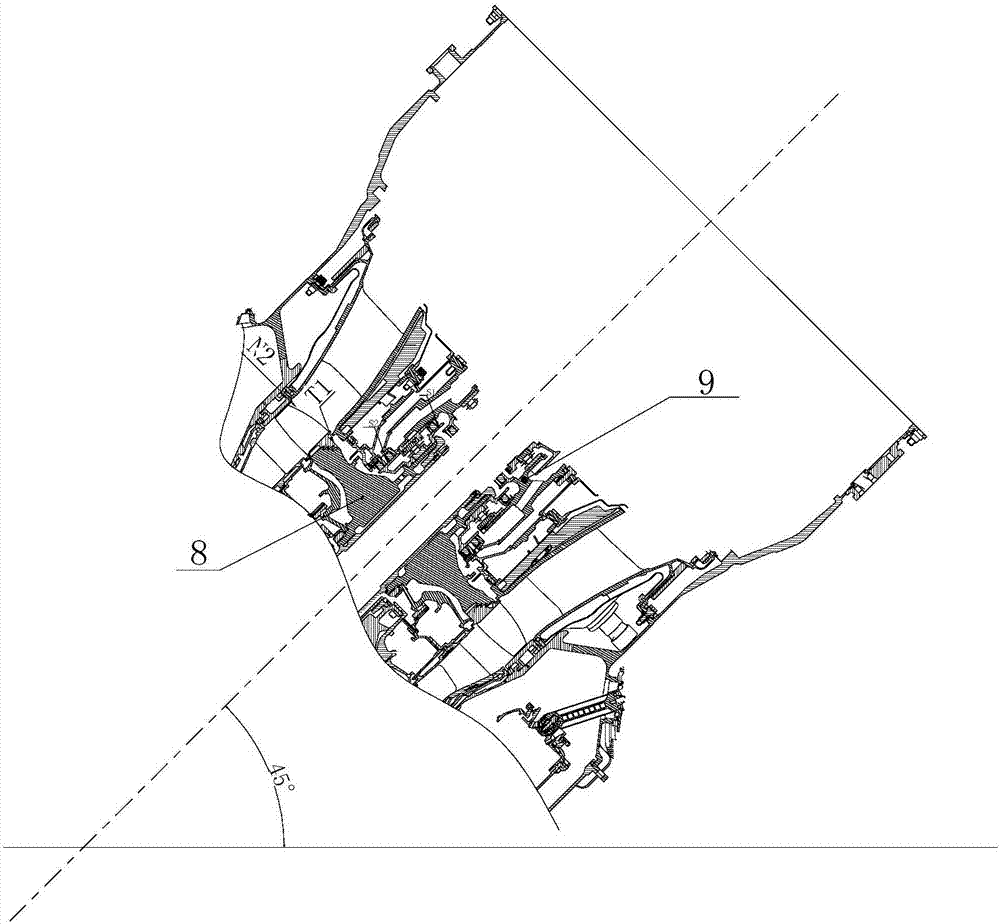

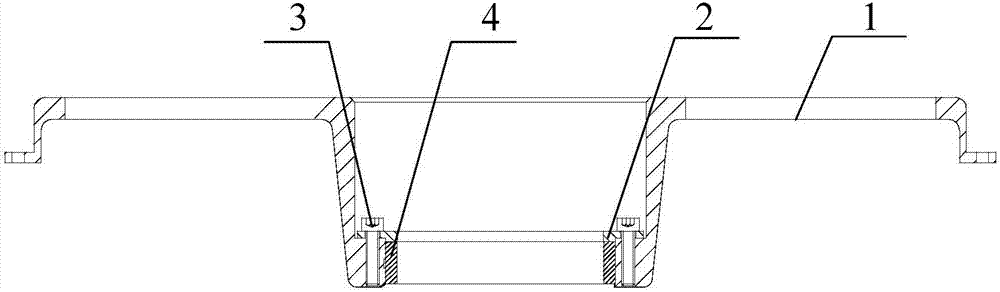

[0032] Reference figure 1 The preferred embodiment of the present invention provides a cantilever fulcrum bounce detection tool. The detection method of the low-pressure turbine rotor bounce value and blade tip clearance on the existing engine is to detect without installing the interstage guide 9, but it will There are the following drawbacks: On the one hand, because the low-pressure turbine rotor 8 is connected to the low-pressure compressor through the long shaft, cantilever deflection occurs during end face detection and tip clearance detection when the support point of the low-pressure turbine rotor 8 is not fixed. As a result, the measured low-pressure turbine rotor runout value and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com