Self-washing-free double-cone PDC cone composite drill bit

A composite drill bit and roller cone technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problem that the PDC bit cannot replace the roller cone bit, etc., so as to solve the time spent at the bottom of the well, reduce the loss of water head, reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

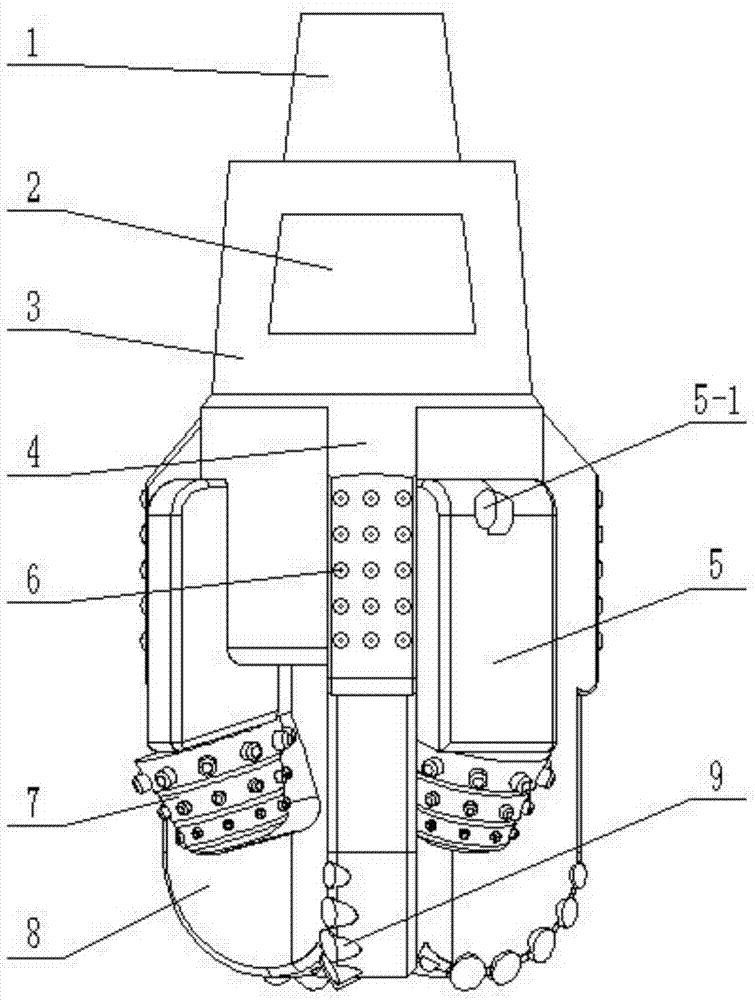

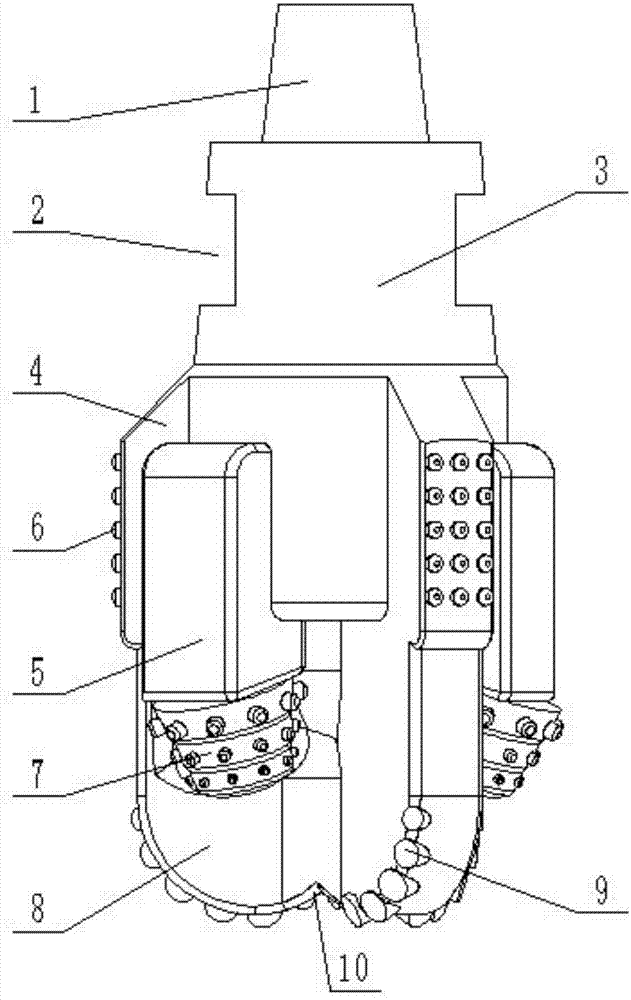

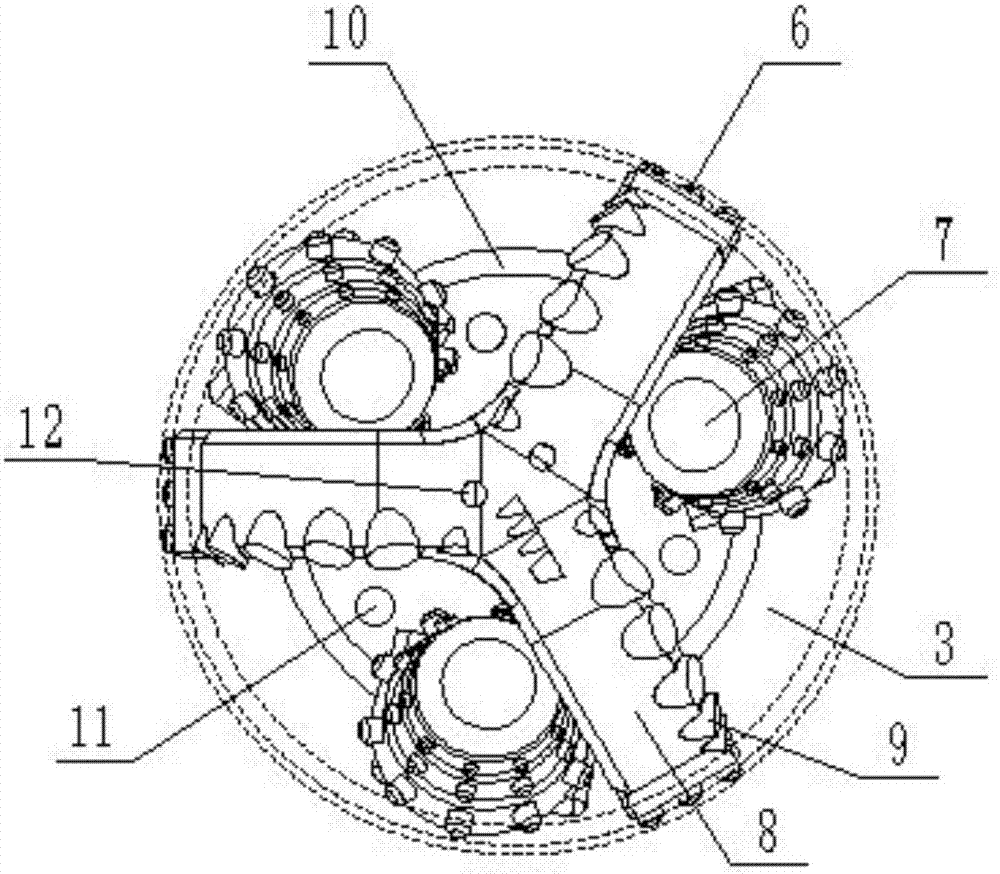

[0030] Combine below Figure 1-10 Explaining this embodiment, the present invention relates to the technical field of petroleum equipment, and more specifically is a non-self-cleaning compound cone PDC roller cone composite drill bit, including: thread 1, shackle cap 2, bit body 3, gauge body 4 , Cone connecting body 5, diamond particles 6, cone 7, crown 8, PDC cutting teeth 9, chip flutes 10, circumferential water eye 11 and central water eye 12.

[0031] The cone connecting body 5 is an inner hollow structure, an oil storage cavity 5-1 is arranged inside the cone connecting body 5, and a cone connecting column 5-2 is arranged at the bottom end of the cone connecting body 5.

[0032] The outer wall of the cone 7 is provided with a plurality of cemented carbide teeth 7-1. The inner wall of the cone 7 is provided with a cone connecting column mounting groove 7-2, and the inner wall of the bottom end of the cone connecting column mounting groove 7-2 is provided with Card slot 7-3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com