Foundation treatment system based on electric heating drainage plates and construction method thereof

A foundation treatment and drainage board technology, which is used in basic structure engineering, soil protection, construction, etc., can solve the problems of small increase in strength, can not meet the requirements of foundation use, etc., and achieves convenient layout, reasonable design, and reinforcement quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

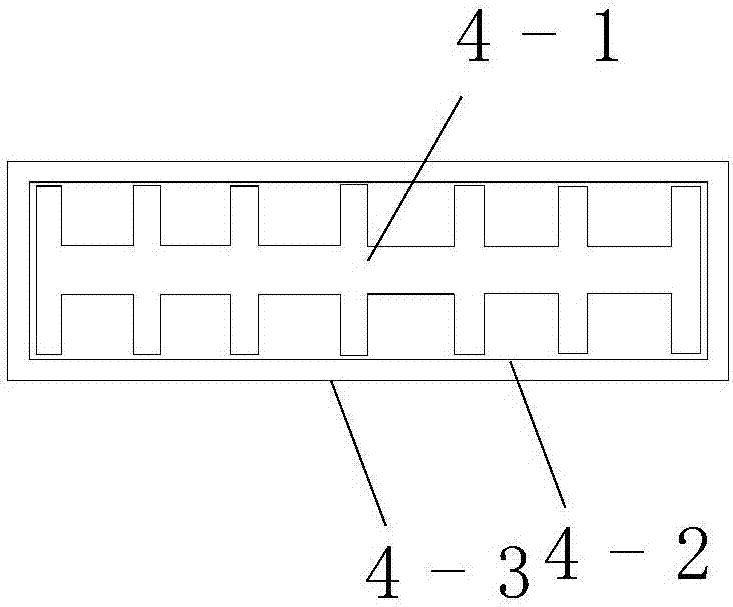

[0033] A ground treatment system based on electric heating drainage boards, including electric heating drainage boards 4, see attached figure 1 , the electric heating drainage plate includes a plastic core plate 4-1, two layers of filter cloth 4-2, 4-3 are wrapped around the plastic core plate, and an electric heating wire 4-4 is arranged in the interlayer between the two layers of filter cloth, so The above-mentioned electric heating wires are arranged in a serpentine shape along the length of the electric heating drainage board (see attached figure 2 ), or the electric heating wire spirals around the periphery of the electric heating drain board (see attached image 3 );

[0034] The above-mentioned electric heating drainage board is vertically arranged in the foundation, the electric heating drainage board is arranged in a lattice, the head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com