Improving method and bell-mouthed type air ventilation structure of air vent of down-hole plane gate

A plane gate and bell mouth technology, which is applied in the metal structure field of water conservancy and hydropower projects, can solve the problems of cavitation in the lintel section, gate vibration, gas in the lintel section cannot be replenished and discharged, etc., and achieve the effect of ensuring safety and reducing gate vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

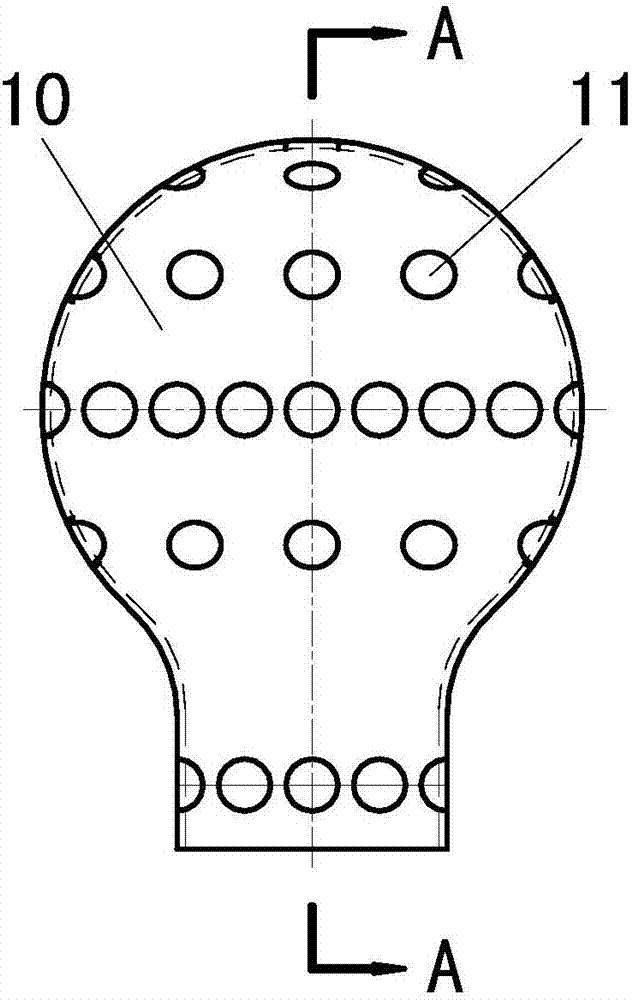

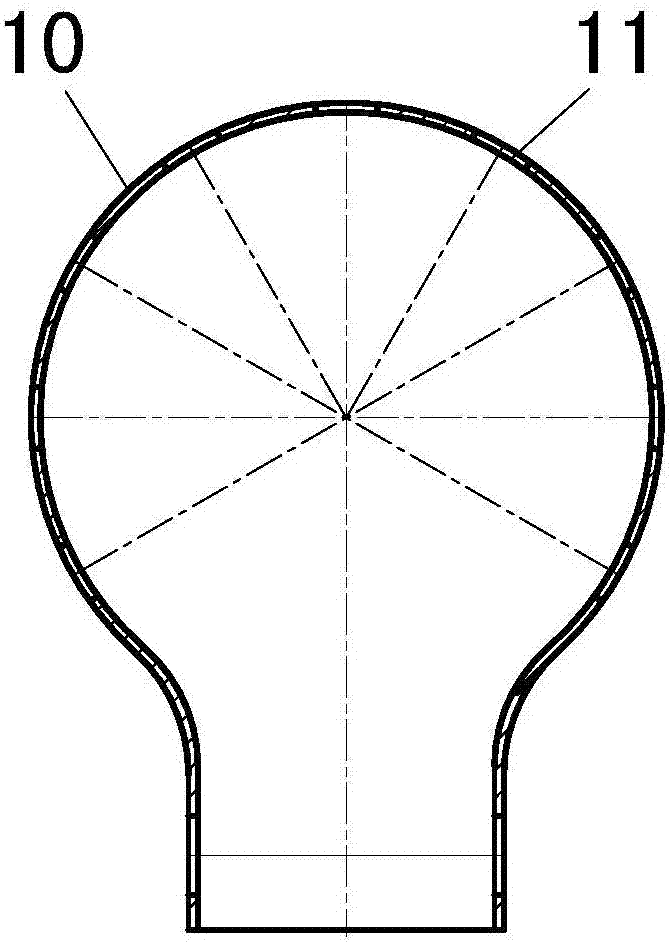

[0024] A kind of down-the-hole planar gate trumpet type ventilation structure, such as figure 1 As shown in the figure, a bell mouth type ventilation hole is arranged on the lower end surface 1 of the door lintel. The bell mouth 17 of bell-mouth type ventilation hole is positioned at the bottom; The bell-mouth type ventilation hole top is circular hole 18;

Embodiment 2

[0026] A kind of down-the-hole planar gate trumpet type ventilation structure, such as Figure 5 As shown in the figure, a bell mouth type ventilation hole is arranged on the lower end surface 1 of the door lintel. The bell mouth 17 of the bell mouth type ventilation hole is positioned at the bottom; The top of the bell mouth type ventilation hole is a round hole 18; to the downstream outer edge of the shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com