Method for detecting state of observation hole cover of coke oven

A technology for checking the fire hole cover and detection method, which is applied to the heating of the coke oven, the door/closer of the coke oven, the coke oven, etc., and can solve the problems of workers' personal and health safety hazards, dissipation, manual inspection, etc., to achieve Improve reliability and service life, avoid irreversible damage, and avoid environmental pollution incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for detecting the state of the coke oven fire hole cover of the present invention will be further described below.

[0031] The method for detecting the state of the burner hole cover of the coke oven includes the following steps:

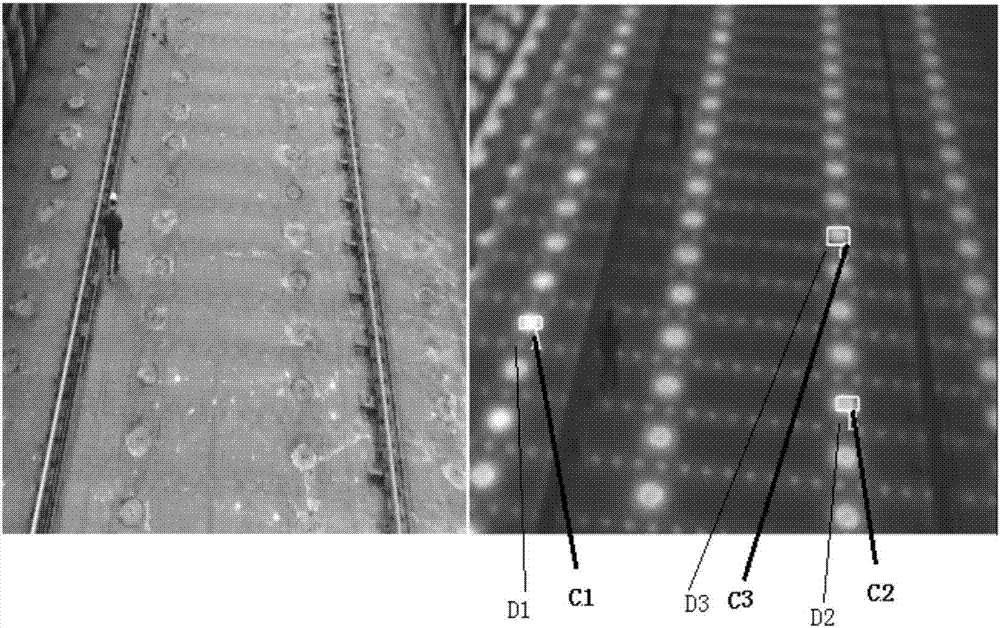

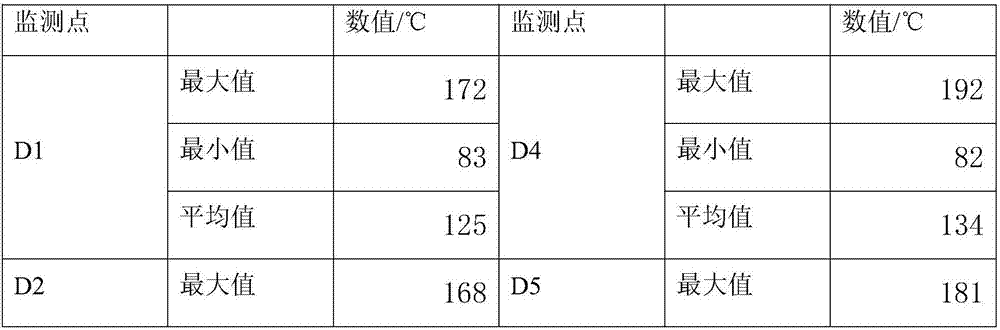

[0032] (1) the temperature detection device is installed on the position where the fire hole cover can be scanned and away from the fire hole cover, and the temperature of the fire hole cover is detected; the temperature detection device is an infrared thermometer or an infrared thermal imager, Obtain infrared images by point scanning, plain scanning or thermal imaging, and calculate temperature data;

[0033] The temperature detection device is installed on the bracket higher than the roof of the coke oven on the coke collecting side, and is used to scan multiple fire hole covers in real time to detect the temperature of the fire hole covers; heat insulation facilities, ventilation facilities and / or rain protection.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com