Composite filter rod supportive of heat exchange

A composite filter rod and capillary channel technology, which is applied in e-liquid filter, application, tobacco and other directions, can solve the problem of reducing consumer satisfaction and smoking quality of cigarettes, weakening the filtering effect of filter rod tow particulate matter, and weakening condensable particles. It can solve the problems of condensation of particulate matter, so as to achieve the effect of suitable for industrialization promotion, reducing the hazard index and reducing the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

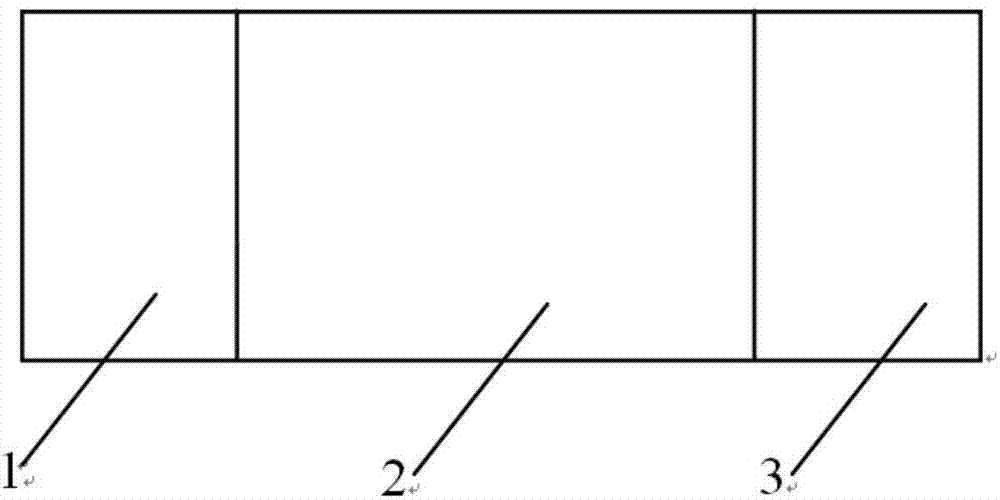

Embodiment 1

[0031]Embodiment 1: The present invention provides a heat-exchangeable composite filter rod. The heat-exchangeable firmware section accounts for 50% of the entire composite filter rod's length, is located in the middle section of the composite filter rod, and has acetate fiber sections at both ends. 2.7Y / 35000 tow is used for acetate fiber filter rod sections 1 and 3, the filter rod length is 5mm, the pressure drop of this section of filter rod is about 170Pa, and the molded paper is 10000CU. The heat-exchangeable firmware section adopts a coaxial firmware section, the length is 20mm, the diameter of the heat-exchangeable firmware section filter rod is 4.8mm, the outer tow is 3.0Y / 32000 tow, and the forming paper is 10000CU. The pressure drop of the filter rod in this section is about 200Pa. Composite the three-section filter rods on a forming machine, and the composite filter rod forming paper is 15000CU. The pressure drop of the ternary composite filter rod in the cigarette...

Embodiment 2

[0038] Embodiment 2: The present invention provides a heat-exchangeable composite filter rod. The heat-exchangeable firmware section accounts for 40% of the entire composite filter rod length, is located in the middle section of the composite filter rod, and has acetate fiber sections at both ends. 2.7Y / 35000 tow is used for acetate fiber filter rod sections 1 and 3, the filter rod length is 5mm, the pressure drop of this section of filter rod is about 170Pa, and the molded paper is 10000CU. The diameter of the filter rod in the heat-exchangeable firmware section is 7.67mm, and there is no molding paper. Because there are through holes for the flue gas passage in this section, the pressure drop is below 50Pa. Composite the three-section filter rods on a forming machine, and the composite filter rod forming paper is 15000CU. The pressure drop of the ternary composite filter rod in the cigarette is about 500Pa.

[0039] The composite filter rod is rolled on the wrapping machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com